Accelerate Your Parts Manufacturing with On-Demand Services

Your Partner in Fast, Precise, On-Demand Parts Manufacturing

- Fastest Customization, Best Precision Delivered

- Highest Flexibility, Best Results Guaranteed

- Smoothest Process, Quickest Solutions Offered

All-Inclusive Custom Parts Manufacturer

First Mold is a national high-tech digital manufacturing enterprise specializing in custom parts making. We’re mainly engaged in the production and manufacture of precision plastic parts and precision metal parts through precision molds, injection molding, rapid prototype, CNC machining techniques.

Our manufactured products are used in a wide range of applications, mainly in automotive parts, medical devices, consumer electronics, etc.

First Mold's factory in Mexico

First Mold’s factory in Mexico mainly serves the North American market, covering regions including Michigan, California, Illinois, Minnesota, Massachusetts, New Jersey, Ohio, Texas, Georgia, Kentucky, Mississippi, North Carolina, West Virginia, Tennessee, Alabama, Toronto, Hamilton, London, Windsor, Montreal, Quebec City, Calgary, Edmonton, Alberta, Vancouver, British Columbia, Monterrey, Toluca, Guadalajara, Querétaro, León, Puebla, etc.

With the core technology developed by our China-based team, we ensure the quality of your products while lowering costs through efficient production management. This allows us to provide you with cost-effective and high-quality solutions.

Customize Plastic And Metal Parts Production Services

One-stop service is a special feature of First Mold. Because we have a complete range of equipment and processes, you do not have to go through the trouble of interfacing with several companies for different steps.

Injection Molding Services

First Mold offers one-stop-shop injection molding services that comprise design support, mold making, injection molding, mass production and surface finishes.

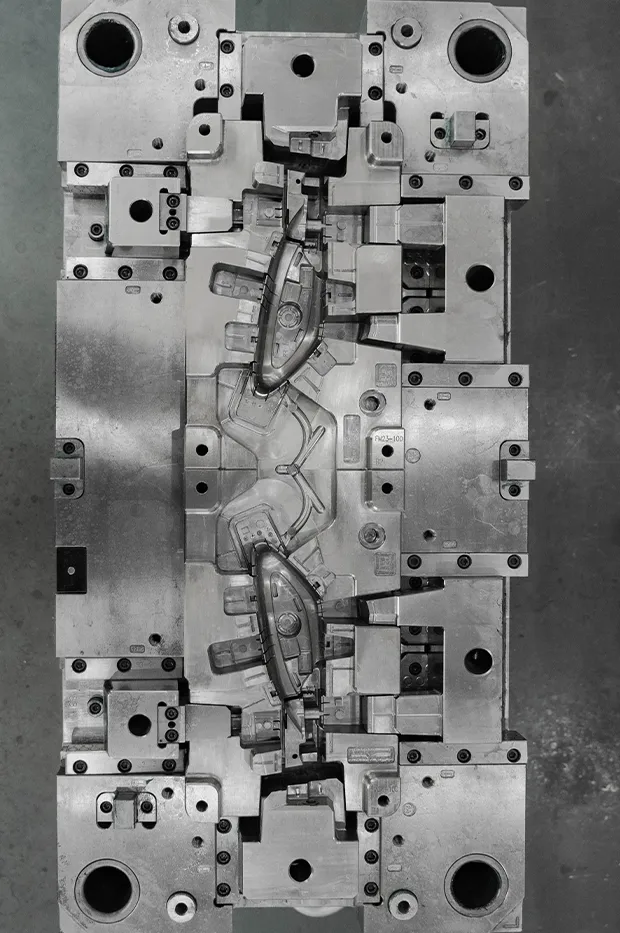

Mold Making Services

First Mold makes molds by means of CNC cutting and EDM machines. Before that, our professional technicians will provide you with free design and material advice.

CNC Machining Services

Our custom CNC capabilities are achieved through CNC milling, 3, 4, and 5-axis CNC machining, CNC turning, Wire EDM, and precision machining.

Rapid Prototyping Services

First Mold is not only fast but also precise in the process of prototypes. More than that, we focus on the rationality of your product design and material selection.

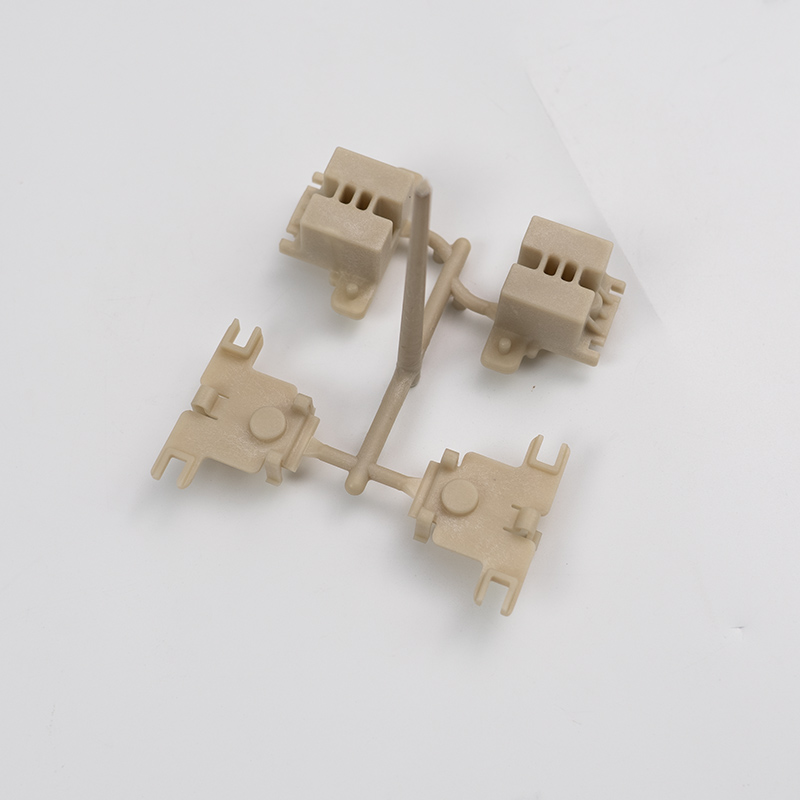

Mass Production of Small Button Parts

Injection Molding of VR Headset Front Cover

Silicone Injection Molded Baby Mask

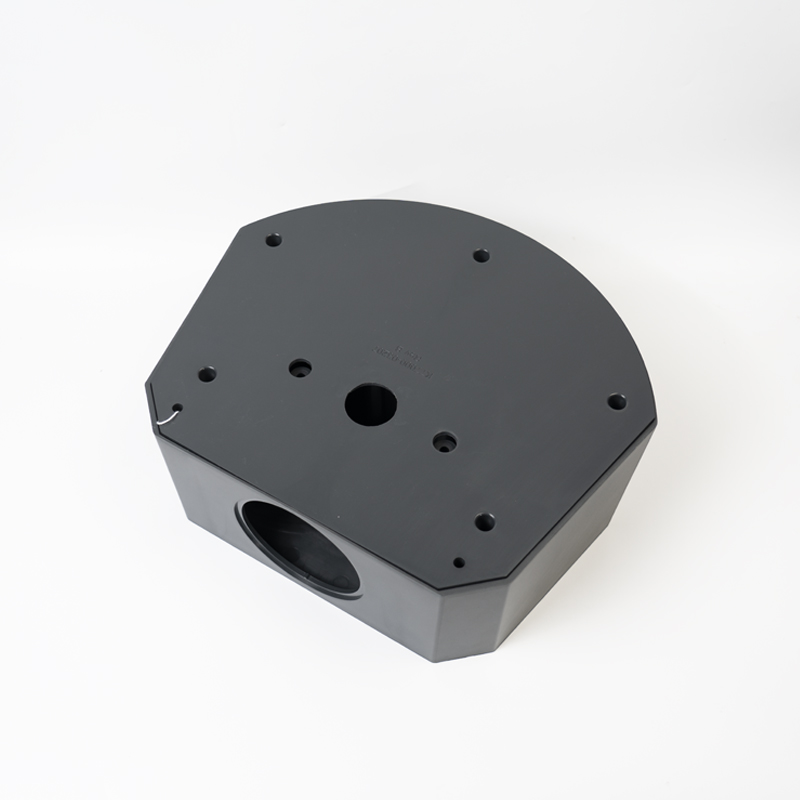

Inspection Equipment Housing Manufacturing By Insert Molding

Production Of Automotive Armrest Bases Through The Injection Molding

Custom Plastic Molding For VR Remotes Controller Housing Manufacturing

Featured Cases

More than ten years of experience in manufacturing plastic and metal parts to satisfy our customers and make progress for ourselves.

First Mold never stops exploring the path of plastic parts and metal parts. Cases are the proof of strength of a good company.

Best Mold & Molding Manufacturer

Building First Mold landscape from long-term visions gathering talents without restricted patterns

- 30,000㎡ factory

- Comprehensive employee structure

- Business global expansion map

First Mold has established a strong presence in over 30 countries, including the United States, Germany, Japan, the United Kingdom, etc.

- Worldwide Presence

- Cross-Cultural Expertise

- International Standards Compliance

Our strength encompasses a range of specialized departments, from engineering to mold design, and quality control to project management.

- Skilled Workforce

- Continuous Training and Development

- Specialized Expertise Across Services

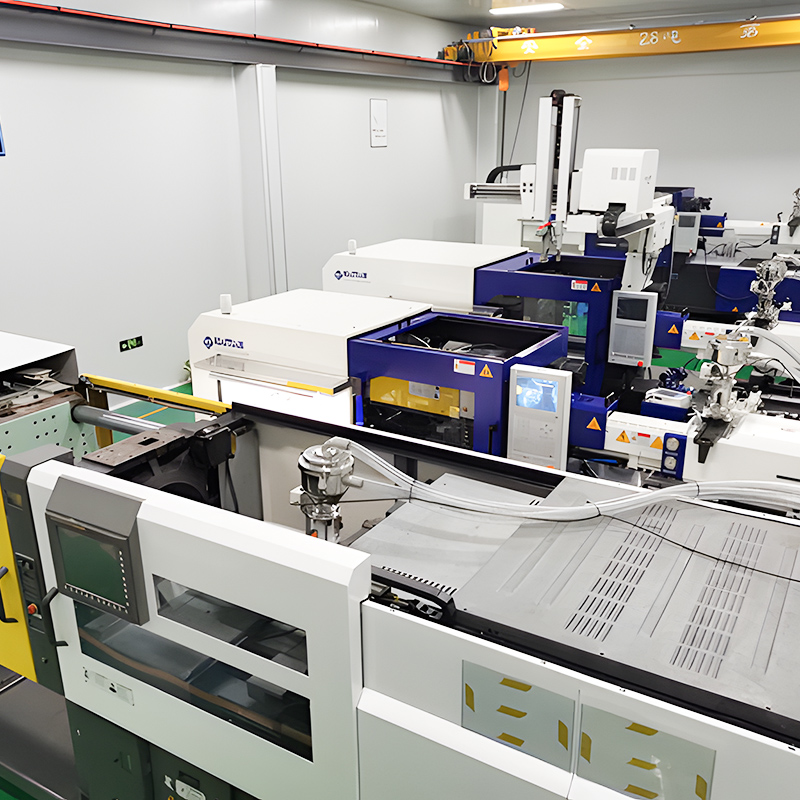

Our select machinery from global leaders enhances our manufacturing capabilities, setting new standards for precision and excellence.

- Advanced Manufacturing Capabilities

- Versatility Across Projects

- Commitment to Quality and Innovation

Their dedication ensures that First Mold remains at the forefront of manufacturing innovation, consistently delivering quality and reliability to our clients.

- Proven Track Record

- Accumulated Expertise

- Long-Term Client Relationships

We believe you will choose us a second time

Only companies that have been in the market for a long time and know what their customers think are your best choices.

Experienced

More than ten years of industry experience, mature quotation system and technical support

Skilled

High-precision production equipment, high-quality production staff, and guaranteed delivery time.

Equiped

Engineers review drawings to eliminate problems, and advanced testing equipment to ensure quality

Thoughtful

Diversified custom processing to save time and effort. Pre-sales and post-sales actively respond to customer needs.

Well-structured organizational framework and sophisticated processing equipment

Mold department, injection department, CNC processing department, quality control department, logistics department, PMC, purchasing department, sales department, marketing department

Injection Molding Workshop

Mold Fabrication Workshop

Mold Machining Workshop

CNC Machining Workshop

Quality Inspection Department

Testimonial

See what our customers said

“When we first requested CNC machining, we tried to contact First Mold. They responded within hours with prices, delivery times and suggestions for our requirements. I am really satisfied with their professional service and high quality control. I would recommend them to my friends Without hesitation.”

“We have been cooperated with Firstmold in injection molding for 6 years. From design to production, First Mold provides excellent and professional injection molding services as well as the high quality products. We feel they are one of the best plastic parts manufacturers We've met in China.”

“First Mold is our the most satisfactory die supplier. They are high efficiency and high quality control. Since 2016, we have cooperated with them on many projects, they also provided professional product suggestions to help us complete the projects. That’s why they’re such a great injection mold company.”

Latest News & Article

Surface Finishing for CNC Machined Parts: Explore anodizing, bead blasting, and electropolishing to enhance durability, aesthetics, and performance.

Injection mold repair tackles defects, reduces downtime, improves output quality, and enhances productivity with precise maintenance methods.

Electrical injection molding shapes precision-engineered components, meeting the demands of modern electronics with innovation, efficiency, and unparalleled durability.

Medical injection molding delivers precision and sterility for healthcare, producing high-quality components that meet strict medical standards.