From basics to advanced concepts, this guide covers all aspects of types of threads. Explore different thread types, their applications, and best practices for optimal performance in structural, product, and manufacturing projects.

Threads are frequently disregarded but undeniably crucial components in the engineering world. Threads are essential for sealing, power transmission, and fastening, and they can be found in everything from tiny screws to massive industrial machines. Gain insights into advanced thread technologies and explore deeper essential knowledge for making informed engineering decisions.

A thread is a produced or cut helical ridge or groove on a cylindrical surface. This exact spiral design forms a mechanical interface that enables the transmission of rotational force or the secure joining of components. Comprehending its foundational components is crucial to designing efficient threads capable of securely joining or fastening components together.

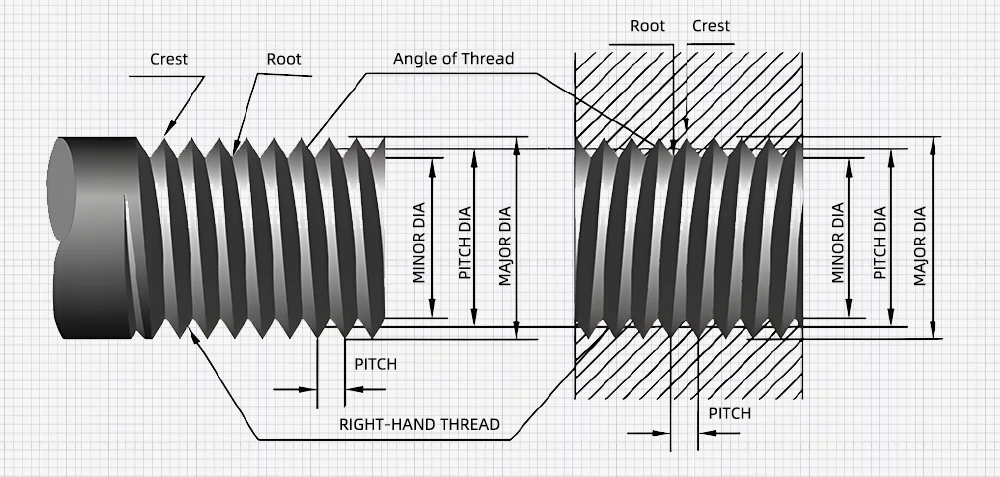

Core Elements Of Screw Thread

PITCH

Pitch represents the axial distance between two successive crests (or roots) of a thread. This should not be confused with the lead, which is the distance a screw thread advances axially in one complete turn. It has a direct impact on the thread’s capacity to advance with each rotation as well as its linear and rotational movement.

ROOT

The root is the bottom surface of the thread. It’s the lowest point in the thread, as opposed to the crest.

FLANK

Frank refers to the straight sides of the thread that connect the crest and the root, forming the sloped surfaces of the thread. They form a solid structure with sloping side surfaces and inclines running from the crest to the root.

CREST

Crest means the highest point of a thread that forms the external surface of the screw.

LEAD

The lead is the axial distance that a bolt or nut travels in a full rotation (360 °). The lead in multi-start threads is equal to the number of starts multiplied by the pitch, whereas in single-start threads, it is equal to the pitch. The smaller the lead, the higher the mechanical advantage.

ANGLE OF THREAD

It’s the angle measured in an axial plane between the thread’s flanks.

MAJOR DIAMETER

The major diameter is the diameter of an imaginary cylinder that surrounds and touches the tops of the external threads. Internal threads touch the bottoms of the threads.

MINOR DIAMETER

Minor diameter also referred to as root diameter is the diameter of the imaginary cylinder at the root.

PITCH DIAMETER

Pitch diameter is the diameter at which tooth thickness equals pitch/2 or the diameter of the imaginary cylinder (concentric to the thread axis) that crosses the surface at that location. The pitch diameter exists halfway between the sharp major and minor diameters on a sharp V-thread shape. However, few threads form this way.

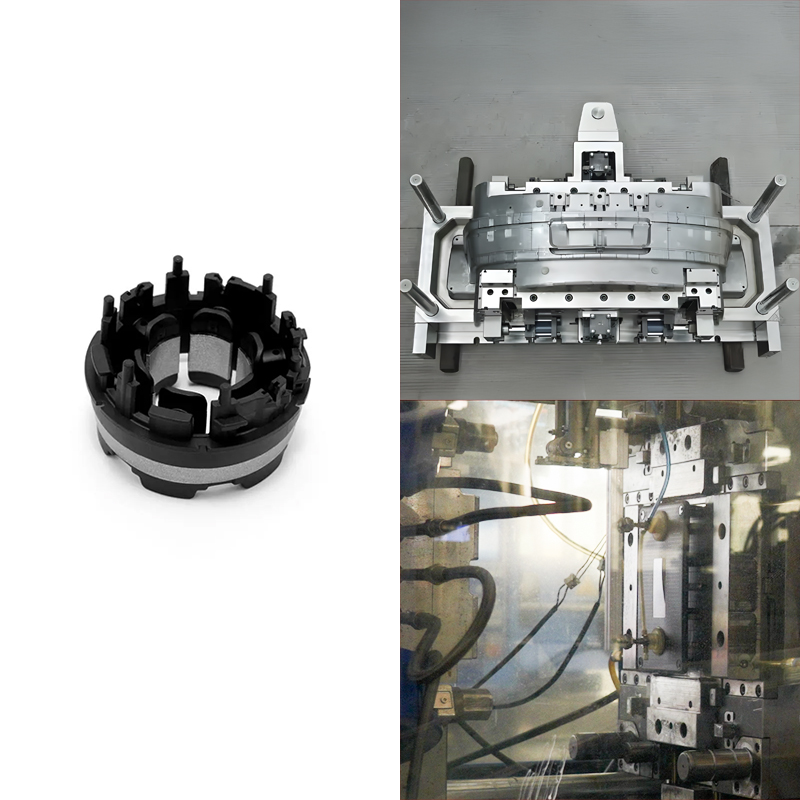

EXTERNAL THREAD

These are threads that are featured on the outer surface of components such as pipes, bolts, screws, studs, cylinders, and shafts.

INTERNAL THREAD

Internal thread forms on the inner surface of the parts, like the threads within a nut, cylinder, or pipe.

RIGHT-HAND THREAD

When a bolt or rod rotates clockwise, its outer surface advances into the nut, and when the screw is positioned horizontally, it slopes upward and left.

LEFT-HAND THREAD

When a bolt or rod rotates counterclockwise, its left-hand thread advances into the nut. When the screw is positioned horizontally, it slopes upward and to the right.

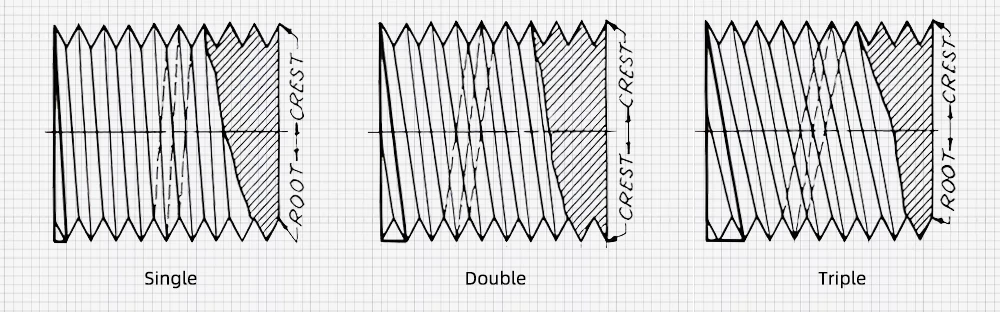

SINGLE-START THREAD

Single-start thread is a single-start thread that has a pitch that coincides with the lead and only one visible helix, or starting point, that runs the length of the thread on a cylinder. The thread pitch causes the nut to travel along the axis when a nut is firmly secured at one location on a threaded bolt and the rod turns 360 degrees.

DOUBLE-START THREAD

The threads on the inside of the nut’s hole are also double-start threads when there is a double-start thread. A nut advances or shifts twice the pitch of the thread when it fits into a double-start threaded bolt or rod, and the rod turns 360 degrees.

MULTI-START THREAD

The multi-start threads refer to two or more threads with the same pitch running parallel to one another. In situations where a system does not require self-locking but rather requires a high translation speed along the thread axis, many start threads apply.

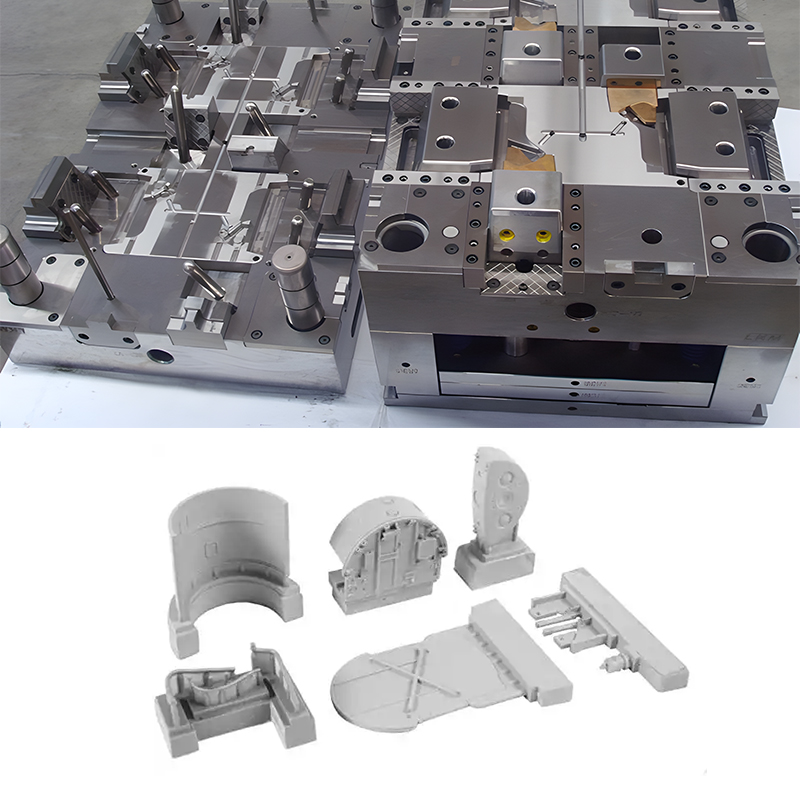

Types Of Threads

The development of various thread profiles has been influenced by historical manufacturing processes and regional preferences, which have led to the standardization of specific thread types for different applications. Additionally, due to unique requirements on the load-bearing capability, there are different thread standards. This is where the thread shape matters. Every type of thread has a distinct purpose, and they are all characterized by unique profiles. This affects the actual appearance and behavior of the thread and comprises of values like pitch and flank angle. The application domain for which a thread is suitable is also determined by the thread profile. Common thread types fall into many groups based on this.

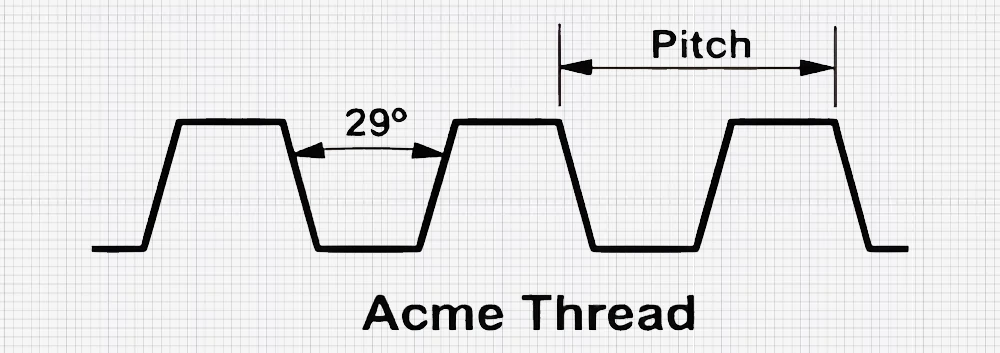

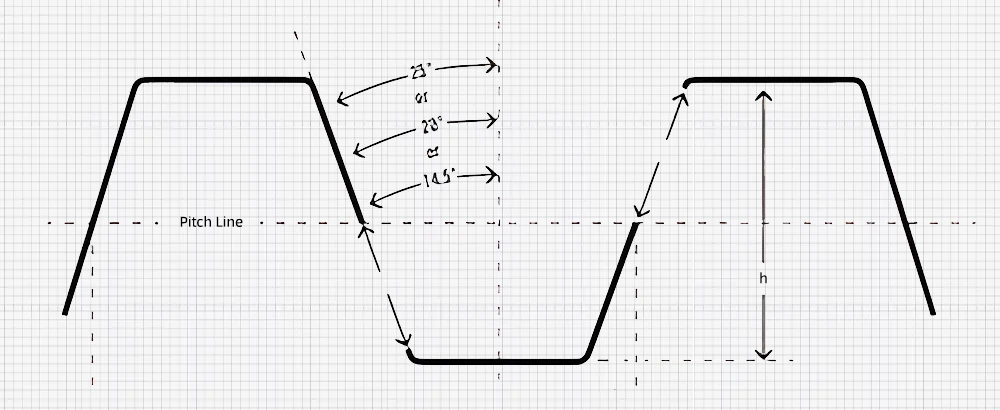

Acme Threads

These threads resemble square threads in general, but they have a tapered shape—that is, they are thin at the top and flat at the bottom. Compared to square threads, it is somewhat simpler to cut on a job. It’s additionally considered to be far stronger. Fixing or unscrewing the split nut on these threads seems easier on their slanting ends. It doesn’t contain any backlash. This thread has a 29° angle of manufacture. Brass valves, bench vices, and screw-cutting lathes are frequently equipped with acme thread.

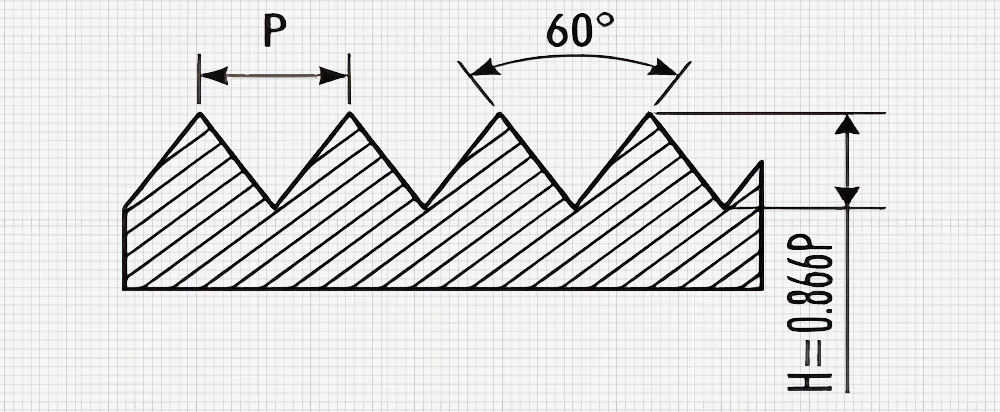

V-Shape Threads

The “V” form of the English alphabet appears in this style of thread. A lathe machine, milling machine, tap, die, and other tools can cut or create these kinds of threads. However, the standards used to make these threads vary. It is the most widely used type of thread.

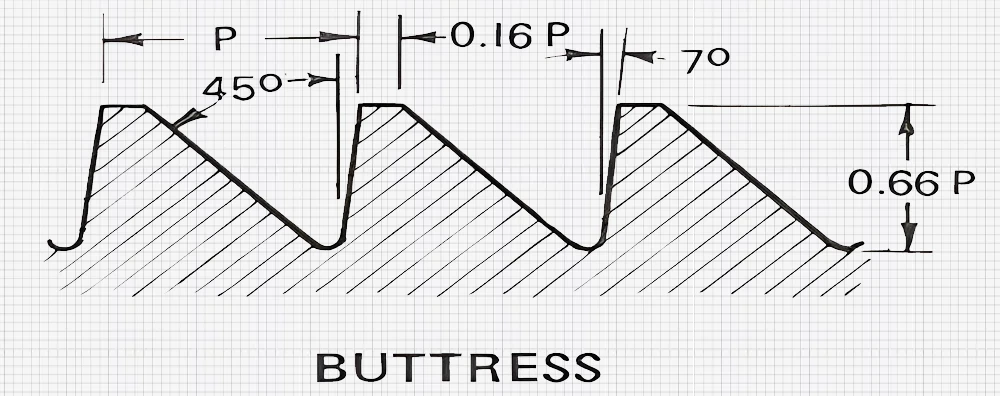

Buttress Threads

This screw thread is triangular, with one face oriented perpendicular to the screw axis and the second face merely sloping. Compared to square thread, it has a stronger pulling force. Square and V-thread advantages are both provided by the buttress thread unit. It is equally as strong as a V-thread and has the same low frictional resistance as square threads. For this reason, it is applicable in situations when there is an excessive draw on one side that needs absorption, much like in a ratchet.

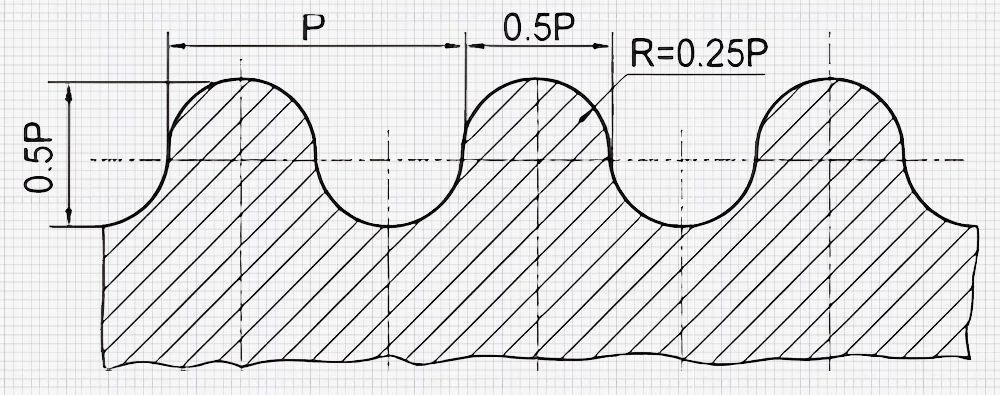

Knuckle Threads

The thread is quite strong. It is usable for both light and heavy, tough jobs. Both the crest and the root on this are half-round. Knuckle threads are designed to perform well in harsh environments where debris might accumulate, thanks to their rounded profile, which resists damage and dirt build-up. This thread modifies the square thread design, allowing for easy casting and rolling. It has a 30° angle. Glass bottlenecks, railway carriage couplings, coupling gears, valves, fittings, slides, hydrants, large molded insulators used in the electrical sector, and other items can all have knuckle threads.

Worm Threads

Though they are deeper than Acme Threads, their shapes are remarkably similar. They are also at a 29 ° angle. Worm threads are commonly used in systems where power transmission occurs at a right angle (close to 90°), such as in automobile worm gear systems. The exact angle can vary based on the specific design. The worm wheels fit the shaft perfectly since three of their teeth are worm threaded in.

Single and Multi-Threads

It is conceivable for a work to have a few distinct, independent threads running concurrently with it. Consequently, when a bolt or screw is fully turned around, it is referred to as a single-threaded screw. Also, a single thread is moving. There is more than one thread present at any given moment in multiple or multi-start threaded screws. The independent threads are starts, and we may have single-start, two-start, three-start, and so on.

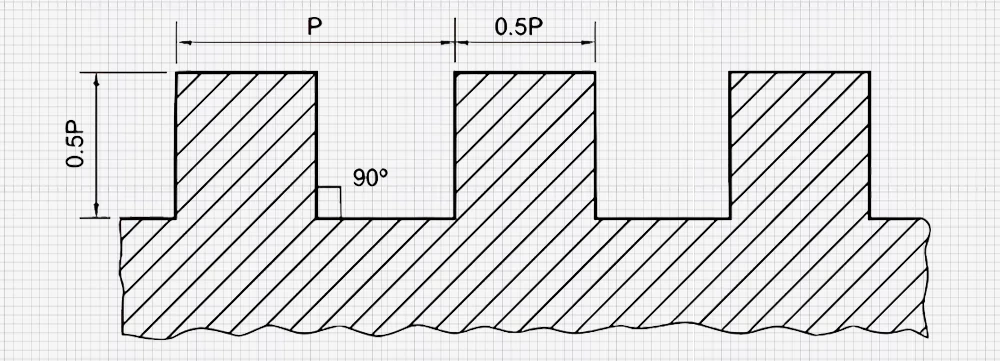

Square Threads

A square thread has an extremely strong root. It is a widely used screw thread that takes its name from its square cross-section. These threads apply in screw jacks, press machines, heavy-lifting apparatuses, power transmission, pressure application, and vice spindle equipment. Though they offer less frictional resistance to movement than Whitworth threads, square threads are not as robust as V-threads. They don’t have a set number per inch or precise measurement.

Taper Threads

This kind of thread has taper threads, which are threads that are cut on a tapered surface. Applicable in shafts such as spindles for polishing. These can be left- or right-handed threads.

These threads have multiple functions.

Mechanical advantage: Applies to lifting mechanisms such as jacks and pulleys.

Precision: Making sure measuring instruments, such as micrometers, are accurate.

Transmission of power: the movement of energy from one place to another.

Speed control: Regulating and reducing motion.

Connecting parts: Assembling bolts and nuts.

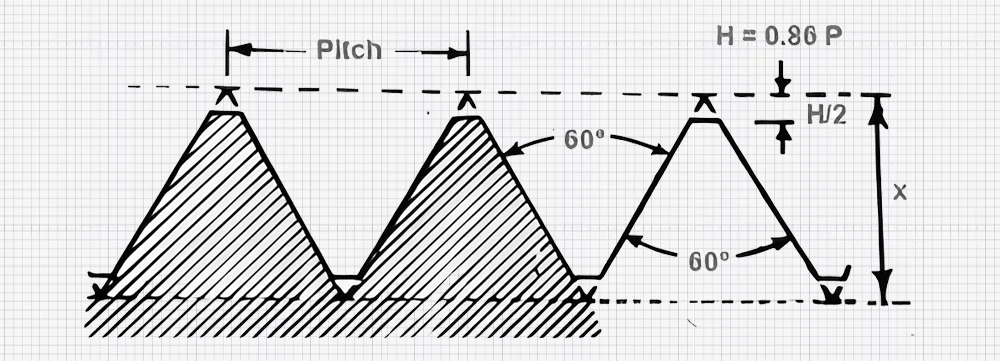

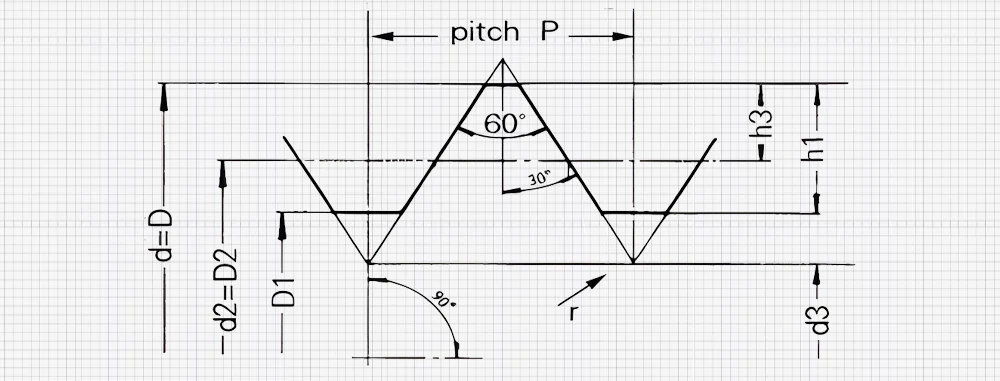

Seller Threads

The American National Thread has a 60° angle and is a V-shaped thread. Its bottom and top are both flat. This extensively used thread was established by the American Standards Institute. Due to its higher strength-to-weight ratio, the National Fine Thread, a thinner variant, often finds use in the automobile and aerospace industries.

Metric thread (M) or International Threads

Arguably the most popular and widely used thread in Europe is the ISO metric thread, standardized globally. It is sometimes referred to as a standard thread. Millimeters measure diameter and pitch. M is the code letter for the metric thread. Its screw is flat, and the root is round. The thread parameters are prepared by Indian Standard (IS) 1330-1958: the nominal diameter in millimeters comes first, followed by the pitch (distance between threads) in millimeters. As an illustration, the notation “M20 x 2.5” denotes a thread having a diameter of 20 mm and a pitch of 2.5 mm, or 20 threads per inch.

British Standard Thread.

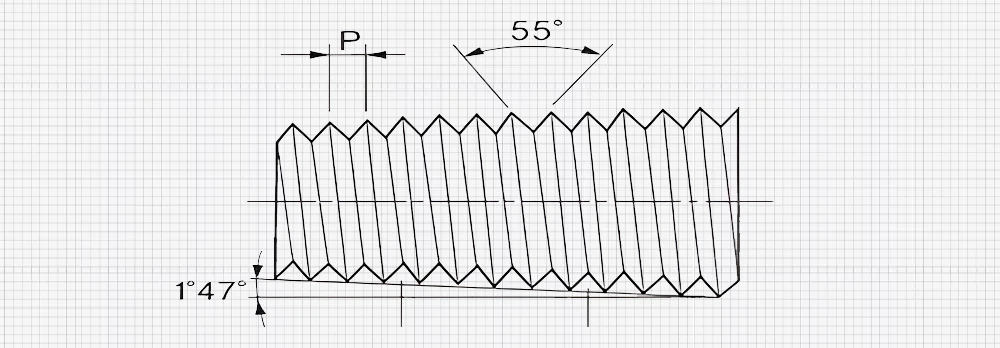

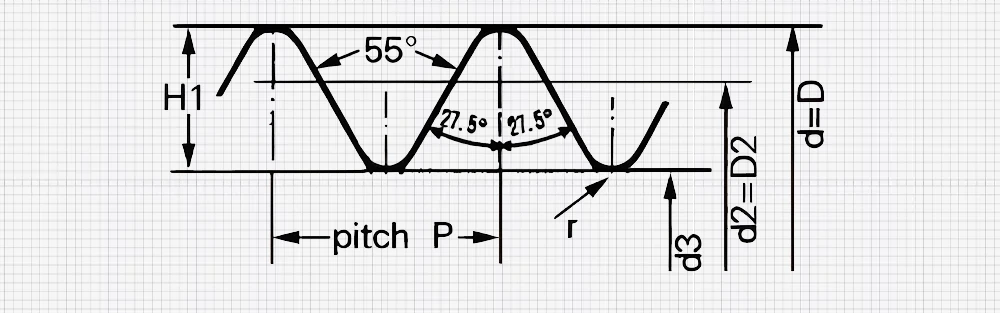

British Standard Whitworth Threads (BSW)

The British coarse control thread was named after the British engineer Joseph Whitworth. This thread was to facilitate interchangeability. The Whitworth thread measures in inches and has a flank angle of 55 degrees. Its crest, as well as root, is round .it has application in many tasks, such as regular nut bolts.

British Standard Fine Thread. (B.S.F)

This thread resembles the BSW thread in form. This thread similarly has a 55° angle, but it has more threads per inch, implying that the threads are thinner. The grasp gets stronger as a result. This threaded nut bolt applies in locations with higher vibration levels.

British Standard Pipe Threads

They have a cut at 3/4 taper per foot and an angle of 55°. They are applicable in steam pipes, gas pipelines, and sanitary pipe fittings. Besides, they are leak-proof because of the taper.

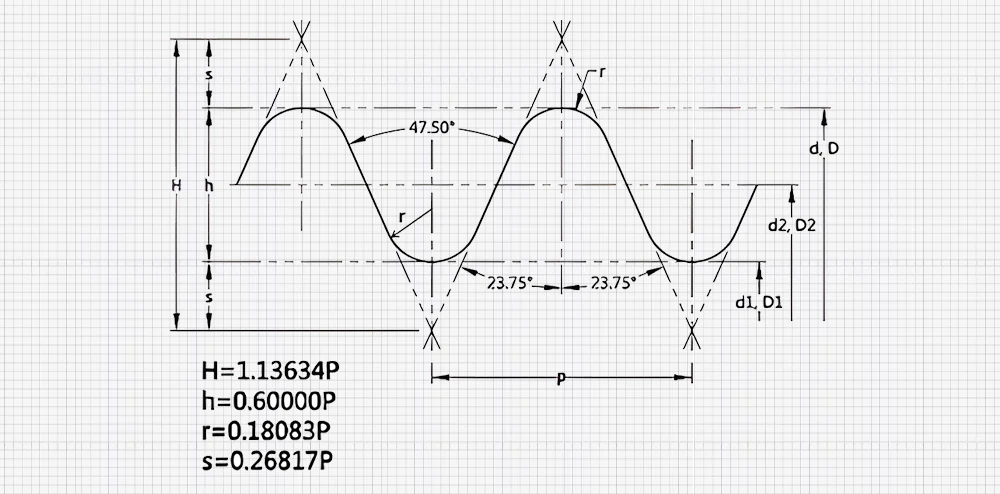

British Association Threads

This thread is present in tiny, sensitive mechanical and electrical devices, including watches, meters, televisions, radios, and electrical appliances. These threads fit 6 mm or 1/2′′ nut bolts and have an angle of 47 1/2°.

An outline of the several thread types and their classifications is given in this table. Specific criteria and modifications may exist.

| Thread Type | Classification | Description | Common Applications |

| V-Threads | General Purpose | Triangular profile, self-locking | Bolts, screws, nuts |

| Unified National (UN) | Standard V-thread for US and inch-based systems | Fasteners, Machinery | |

| Metric | Standard V-thread for metric systems | Fasteners, Machinery | |

| Whitworth (BSW) | British standard V-thread | Older British fasteners | |

| Square Threads | Power Transmission | Square profile, high efficiency | Lead screws, jacks |

| Acme Threads | Power Transmission | Modified square, less efficient but stronger | Lead screws, power screws |

| Trapezoidal Threads | Power Transmission | Trapezoidal profile, high load capacity | Lead screws, machine tool slides |

| Buttress Threads | Thrust Loads | Asymmetrical profile, high thrust capacity | Thrust bearings, clamping devices |

| Worm Threads | Power Transmission | Helical thread on a cylindrical body | Worm gears, screw conveyors |

| Pipe Threads | Sealing | Tapered threads for sealing | Pipe fittings, valves |

| NPT (National Pipe Thread) | Tapered pipe thread for US and inch-based systems | Pipe fittings, valves | |

| BSP (British Standard Pipe) | Tapered or parallel pipe thread for metric systems | Pipe fittings, valves |

Thread Design And Consideration

Thread design is an essential engineering component influenced by elements including load, material, environment, and application. Designers take thread profile, pitch, depth, and tolerance into account to maximize performance. Numerous types of loads influence the thread strength, including static, dynamic, and fatigue loads. Durability, wear resistance, and corrosion protection are all impacted by material choice. Environmental variables such as humidity and temperature affect thread performance. Furthermore, thread function—whether for sealing, power transmission, or fastening—depends on the particular application. Through meticulous evaluation of these factors, engineers can choose or create threads that are suitable for a variety of engineering tasks.

Thread Failures And Prevention

Thread type affects thread failures. Square threads are more likely to gall and seize than V-threads, which tend to strip more frequently. Acme threads combine elements of both, while root fatigue can occur in buttress threads. Pipe threads can strip or fail from corrosion, while metric threads are prone to general failures depending on thread class and load. By addressing these factors, the risk of thread failures can be significantly reduced.

Importance of Thread Types and Future Trends

A comprehensive grasp of thread technology is indispensable for engineers. Because threaded components are so common in engineering systems, this understanding is essential to their design, selection, and use. Engineers can successfully troubleshoot problems, optimize component performance, and cut costs by having a thorough understanding of thread categories, materials, and production methods. Furthermore, guaranteeing product dependability and safety requires a strong basis in thread technology.

More capabilities for already-existing thread types will probably be the main emphasis of future developments in thread technology. This involves creating new materials with increased strength and durability, investigating cutting-edge production processes for intricate thread geometries, and incorporating intelligent technologies for threads that can self-monitor and adapt. Additionally, developing sectors will need to focus on researching ways to optimize thread performance in difficult settings, like corrosive environments or high temperatures.