In the modern market, the ability to develop a new product is not just for competitive advantage but also a necessity. Every industry is always trying to keep up with technological developments and satisfy the ever-evolving needs of its customers. Product designers and structural engineers depend heavily on the creation of new goods. The result is to bring solutions that are not only structurally sound and sustainable but also practical and visually beautiful.

Why Develop a New Product?

New engineering product development (NPD) spurs growth and innovation for companies helping them to stand out. It means turning concepts into workable solutions that satisfy customer demands and increase market share for product designers.

Many businesses follow a structured NPD to enable their product to reach their target market.

For structural engineers, it means making sure their designs are workable, safe, and dependable while addressing practical and regulatory considerations. Adopting this strategy facilitates the communication between engineering and design, leading to successful product launches that meet or surpass expectations.

The most important stages of this process are the design and development stages where the product comes into shape. Product engineers are responsible for turning those ideas into a tangible reality. They are instrumental in driving technological progress and commercial success.

Whether you are working on hardware, a service, or a product, it is essential to follow some steps to start and finish a new product development successfully.

Product Engineering and Product Development

Achieving a successful new product development process requires both Product Engineering and Product Development.

Product engineering focuses on developing, designing, and testing products to meet the required standards and performance expectations. Product development encompasses activities like market research and conceptualization. Both processes are crucial to creating successful products. Product development is like dreaming of a cool new thing, and product engineering is making that dream a reality.

In this article, we will delve into Six (6) steps that can help plan, execute, and deliver the project.

1. Define the problem

Identifying the problem that your product aims to solve is the major thing in product development is to identify. It’s crucial to comprehend the requirements and challenges faced by intended consumers.

1) Understanding the problem

- Identify the need: this could be a design flaw in an already existing product or a need or an entirely new product. A product may involve usability problems or unfulfilled design requirements.

- Assess the market need: the state of the market now to see if identical issues are being handled.

- Technical Viability: feasible commercial potential and whether it can be developed realistically using current technologies.

2) Gathering information

- Industry research: Carry out research and reports from the industry to comprehend more general trends and difficulties in the subject

- Technical Feasibility Studies: Discuss the technical details of your suggested solution with engineers. Like, limitation of designs, structural integrity, and materials.

- Competitor Analysis: Study competitors’ products to find gaps and shortcomings in existing solutions to get innovative.

2. Generate and validate solutions

To accomplish the project objectives and satisfy customer expectations, conceive various concepts and functionalities. Figure out and test potential solutions that address the issue and benefit your clients.

1) Generating Solutions

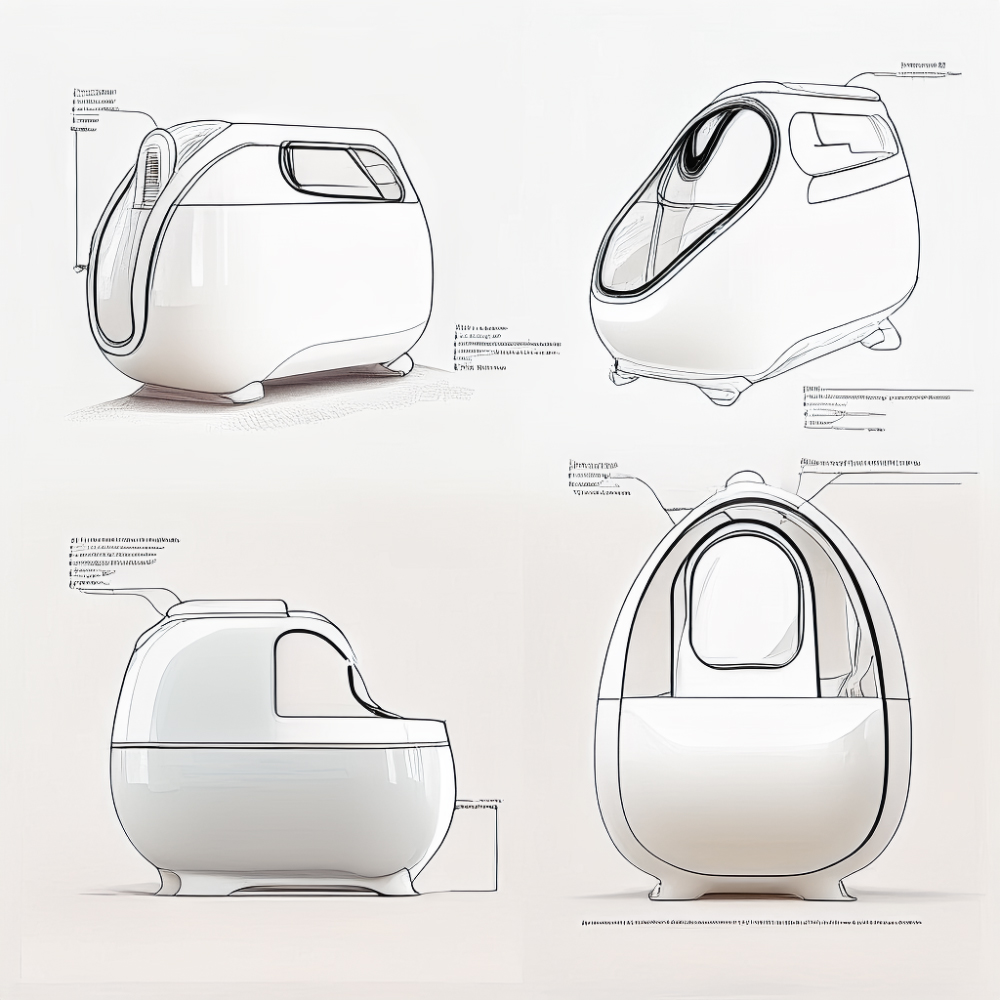

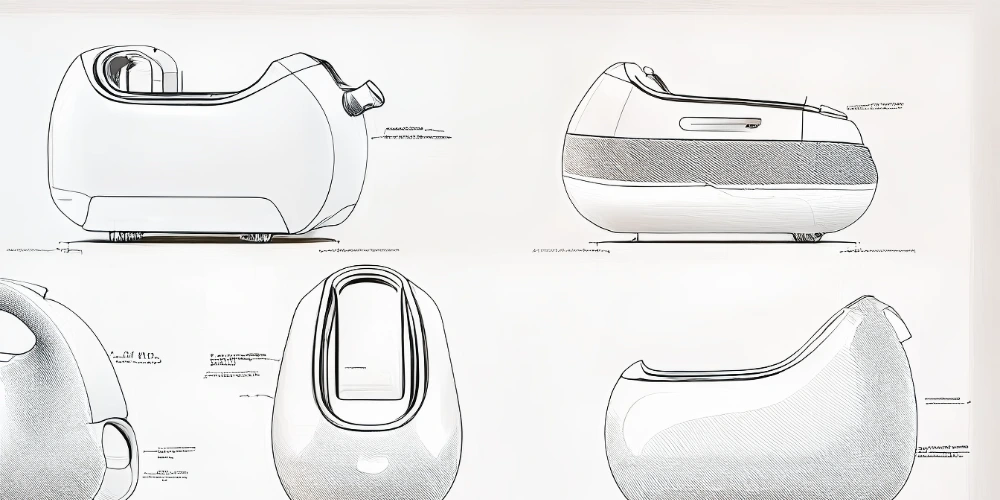

- Conceptual Design: Using wireframes and mockups, create preliminary design concepts. These resources enable you to explore various design alternatives and functions while successfully visualizing and communicating your ideas.

- Brainstorming: brainstorming meetings with your group to provide concepts and solutions. Consider different opinions and encourage creativity.

2) Validating Solutions

- Prototyping: Simple sketches, 3D models, and working prototypes of the product are made possible. These models can be made with tools like CAD software and rapid prototyping technologies (like 3D printing).

- Usability Testing: Test the prototypes’ usability to see how well they satisfy their requirements. Gather feedback on the technical aspects.

- Feasibility Analysis: Test the prototypes’ usability with structural engineers and product designers to see how well they satisfy their requirements.

- Iterative Improvement: Make necessary adjustments to your prototypes based on input from testing and analysis. Fix the problems.

3. Plan and prioritize the development

Planning and setting priorities when you develop a new product is essential to see the engineering product developed successfully.

1) Organizing the process to develop a new product

Resource Allocation: Determine which personnel, materials, and tools are needed for each activity. All resources should be evenly distributed to avoid delays.

Assign Roles and Responsibilities: Assign clear duties and responsibilities to team members.

Break Down Activities: Break the development process down into more manageable, smaller jobs and activities. This makes sure we tackle every part of the product in a super organized way and helps us get a grip on how the whole process flows.

2) Prioritizing Features and Tasks

Task Backlogs: Make a backlog of features and tasks, then rank them according to importance and urgency. Regular review is necessary.

Roadmaps: Create a product plan that details the deadlines, deliverables, and important milestones. This enables tracking development through a visual depiction of the project’s advancement.

Feature Prioritization: utilize strategies like the MoSCoW method (Must-have, Should-have, Could-have, Won’t-have) to rank features according to their significance and effect on the product’s success.

Agile Techniques: agile project management techniques, like Scrum or Kanban, organize and prioritize the work.

4. Building and testing an engineering product

The most important step is crafting the prototype and texting to get the results. Here one needs the best practices and tools for the product engineering domain.

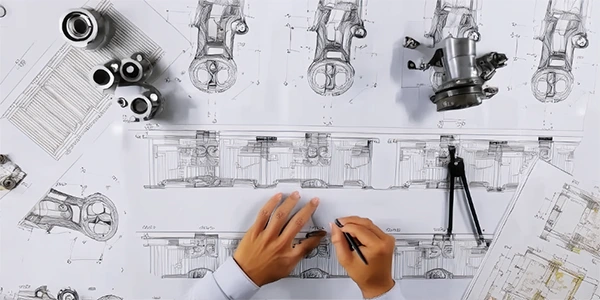

In this phase, the product engineer gets heavily involved in the development. They introduce engineering solutions to optimize designs. For example, design for manufacturability (DFM) and collecting CAD data for technical details.

Testing the product must take place during the entire development cycle. This will ensure the product meets the requirements like, performance, quality, security, and usability.

1) Building the Prototype of an engineering product

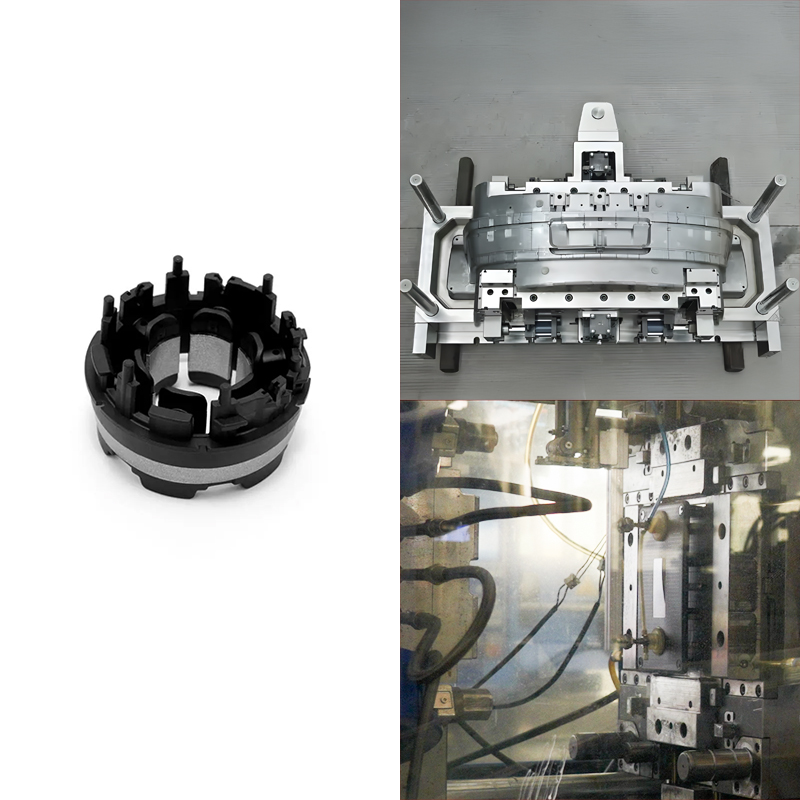

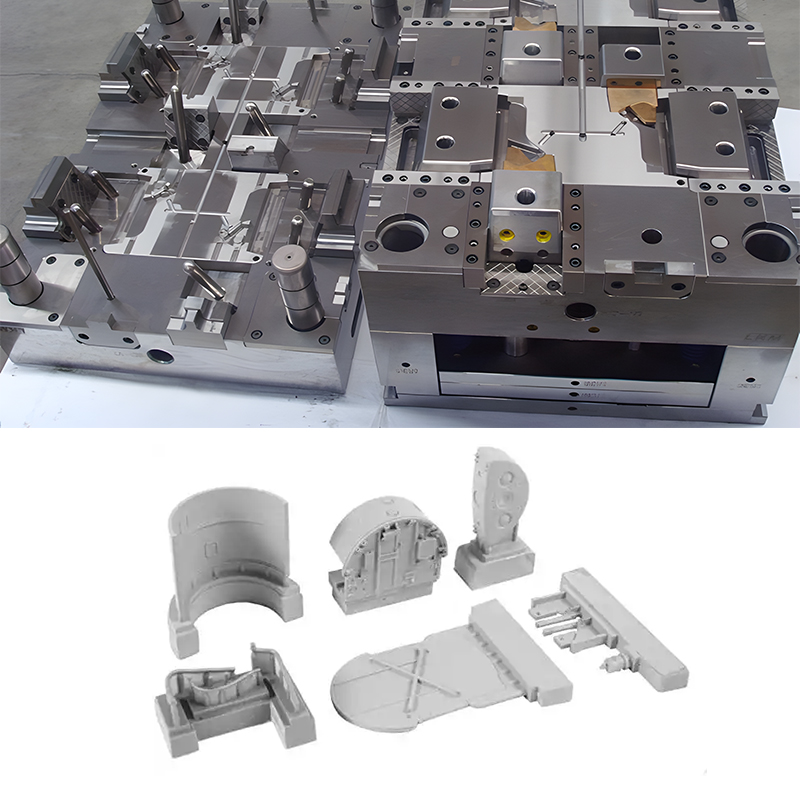

Engineering product Solutions: During this stage, product engineers are essential because they apply engineering solutions to optimize designs. Design for Manufacturability (DFM) is a technique that aids in producing more economical designs. CAD software is another tool that engineers use to create precise technical requirements and guarantee that every component is created correctly. CAE (computer-aided engineering) helps analyze and optimize product designs before prototyping them.

Prototyping Tools: Prototyping can be accelerated by using tools like CNC machines for precise component manufacture and 3D printers for rapid prototyping.

Material Selection: Selecting the right materials per the product requirement. To guarantee that the finished product operates as anticipated, consider material properties like strength and durability

2) Testing the Product

Performance Testing: the product’s functionality should satisfy functional and design requirements. This involves conducting tests in a variety of scenarios to mimic actual use.

Security Testing: Security testing is done on items that involve data or sensitive information. To find flaws and provide a strong defense against possible threats.

Usability Testing: To evaluate the usability and user experience of the product, and get end-user feedback. User testing sessions are one way to do this when users interact with the product and offer feedback on its functionality and conveniences.

Quality Assurance: quality assurance procedures are important to find and fix product flaws and discrepancies. Maintaining high standards can be achieved by utilizing strategies like quality audits and statistical process control (SPC)

5. Launch and market the product

To launch the product for the market, prepare the market strategy, launch plan, and feedback mechanism. Communicating the information about the products to target customers is essential. Use communication channels to reach as many people as possible. Make follow-ups and monitor the launch metrics to provide information on how effective your communication

1) Preparing the Market Strategy

Define the Value Proposition: state the value proposition of your product and its special advantages. Emphasize how it solves certain issues or meets the needs of your target market.

Target Audience: Determine which important audience segments to focus on and then craft your message to appeal to each one. It is easier to craft messages that captivate your target when you are aware of the requirements and problems these groups face.

Competitive Analysis: To find gaps and possibilities, examine the marketing techniques of your competitors. Position your product differently in the market by using this knowledge.

2) Developing the Launch Plan for an engineering product

Communication Channels: Select appropriate channels to reach your target audience effectively. Mix all types of media.

Launch Events: To highlight the features and capabilities of the product, think about holding webinars, live or virtual launch events, or product demos.

Feedback Mechanism: Establish mechanisms to gather early adopter and customer feedback. To learn more about user experiences and potential areas for development, conduct surveys, read online reviews, and communicate with customer service agents.

Monitoring and Analyzing Launch Metrics: use KPIs to measure the launch success. Analytics tools will measure the effectiveness of the platform.

6. Evaluation and Improvement

Collect and analyze the feedback and data from users. It’s important to determine the success rate and your product effectiveness using KPIs such as loyalty, customer satisfaction, and lifetime value. Based on the results, implement changes and enhancements to the product.

Benefits of New Engineering Product Development

To remain competitive and relevant in today’s market, companies must prioritize the development of new products. Companies may stay ahead of the curve in their sectors, expand, and prosper by consistently inventing and creating new products. Here are a few strategies for leveraging the advantages of new product development to grow your company.

- Save Money: Before new items are introduced to the market, their effectiveness in the NPD process may be determined. This allows you to modify your idea to fit the market needs or scrap it completely to save time and money.

- Innovation and Idea Generation: Creating and sustaining an innovative culture is essential to the company’s and its employees’ financial success. The new product development process drives the company’s fresh ideas.

- Strengthen and Formalize the Concept Development Process: At the start of the new product development life cycle, you must clearly define your product concept, just like you would with a new company. The process is necessary to the target customer, which involves defining the product in terms familiar to them.

- Concept Testing: Concept testing and concept development go hand in hand. Testing an idea with the target audience in a real-world setting after it has been finalized is important. This entails utilizing market research techniques to provide prospective buyers with a tangible sample or thorough product description. By interacting with them and getting their feedback, you can learn important things that will help you improve the product and customer experience.

- Marketing Strategy: The product’s marketing strategy can benefit from the new product development process. After your notion has been developed and tested, it makes sense to move forward. You can use the information you gathered throughout the development stage as a marketing plan.

Future trends of New product development

- Sustainability and Eco-Friendly Design: sustainability is a major focus in product engineering, not just a trendy term. In the future, we will see a very eco-conscious consumer base that demands businesses to perform responsibly. In recent times, to reach a socially conscious consumer, the industry must use recyclable materials, choose energy-efficient production processes, and produce eco-friendly goods.

- 3D Printing and Additive Manufacturing: 3D printing and additive manufacturing are shaking up how we prototype and make products. New developments will enable engineers to make complex forms and design adjustments more quickly than they could have with outdated techniques

- Robotic Process Automation (RPA): In product fields, design, and production, robotic process automation, or RPA, is replacing manual labor-intensive operations based on rules. It’s excellent for optimizing processes and increasing efficiency.

- Digital Twins: Virtual replicas of actual systems or things, or “digital twins,” are gaining popularity in product engineering. They let you perform in-depth simulations and gain a better comprehension of a product’s operation. Applications for this technology may include manufacturing, urban planning, and aircraft.

- AI and Machine Learning Integration: AI and ML aren’t just sci-fi anymore they are revolutionizing product design, manufacture, and usage. AI tools will assist engineers in producing more inventive designs, anticipating when a product will require maintenance, and streamlining the manufacturing process. Moreover, ML algorithms will aid in quality assurance and product performance prediction.

Conclusion

To wrap it up, developing a new product is all about understanding what people need and looking for creative solutions. To make something that truly stands out, it is imperative to maintain flexibility and a customer-centric emphasis.