In engineering design, selecting the most appropriate CAD or computer-aided design system will significantly affect a project’s speed, precision, and success. NX CAD, SolidWorks, and Creo are today’s leading CAD software. All these software platforms present different features and functions to provide customized solutions.

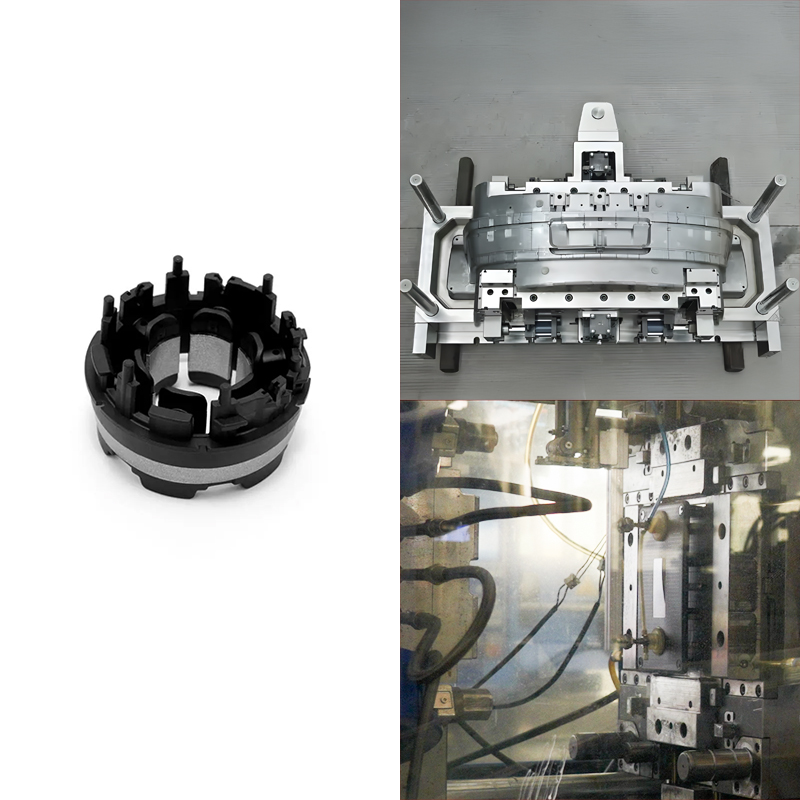

The NX CAD, a Siemens product, is a tool for designing products, engineering, and manufacturing necessary to offer the best solution for designing complex products. It particularly suits industries such as aerospace and automotive, where tight tolerances and design to production techniques are critical.

SolidWorks targets different industries, especially SMEs. It has a simple graphic interface and powerful modeling capabilities. This makes it one of the most popular choices for engineers and designers.

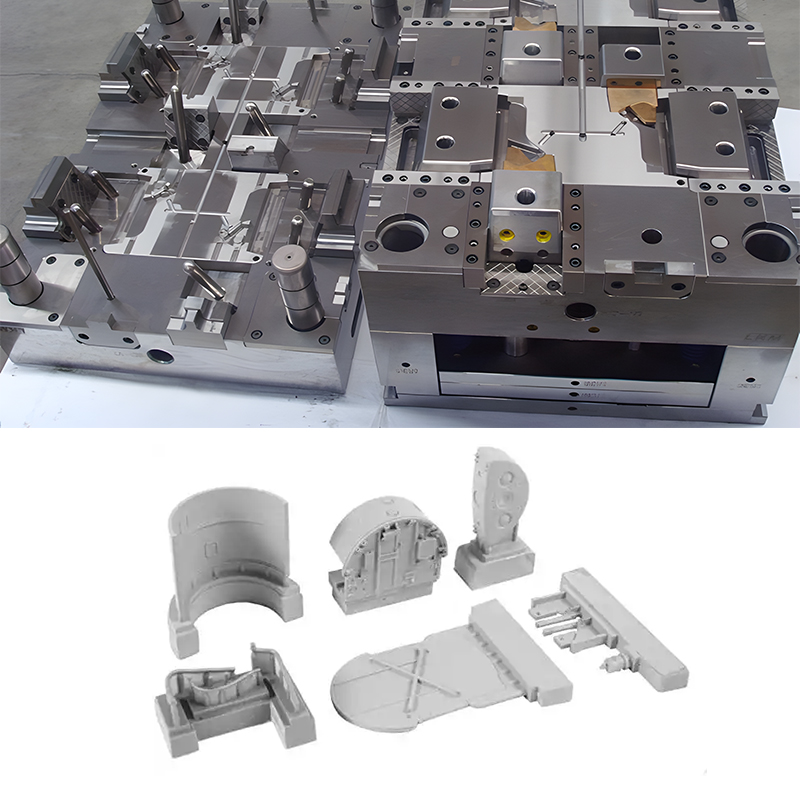

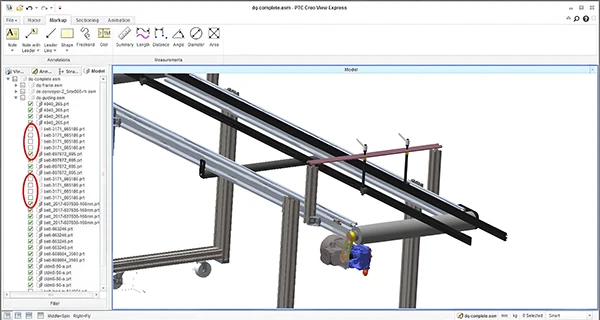

Creo by PTC is another famous solution with an impressive tool for parametric design and reasonable finesse in working with 3D CAD and 2D drawings. It is applicable in machinery, electronics, and consumer goods.

Choosing the right CAD software for a specific engineering project is not just a matter of adaptation. Instead, it is a matter of strategy. The proper tool selection will help to accelerate the workflow, decrease the number of mistakes, and enhance teamwork. This leads to cost optimization and faster product release.

On the other hand, making a wrong decision may cause the process to become lengthy and costly and produce a product that does not meet the standard. Therefore, it is critical to pinpoint each CAD application’s key advantages and disadvantages to make the right choice.

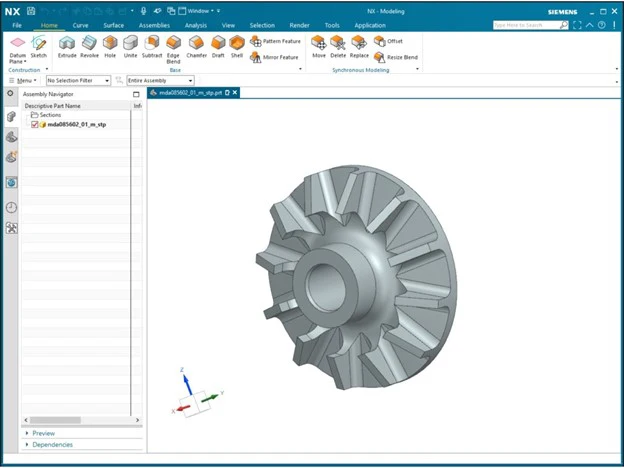

Overview of NX CAD

NX CAD is Siemens Digital Industries Software’s specialized three-dimensional computer-aided design (3D CAD) tool. This application is helpful in various fields, such as designing products and drawing and manufacturing objects. NX CAD is an integrated application incorporating CAD, CAM, and CAE system features. This next-generation solution meets the needs and addresses the challenges facing engineers and manufacturing professionals throughout the product development and manufacturing cycle in a single, integrated package.

Core Capabilities of NX CAD

NX CAD includes functions to create states, cutting-edge assemblies, and limitless surface models. Some of the common forms of modeling are parametric modeling and direct modeling. However, it is beneficial when dealing with interactions, dependencies, and constraints between assemblies.

Specialized documentation and drafting capabilities are available to generate accurate two-dimensional drawings of a three-dimensional object to a specified scale.

In addition, NX CAD has an Analog Application, which includes structural, thermal, and fluid Analysis based on Finite Element Analysis (FEA). It also applies to computational fluid dynamics (CFD) to improve the design and engineering execution.

Industry Applications

Due to its reliability, NX CAD is adaptable and applicable across industries.

Car manufacturing is helpful in virtually all phases of designing, simulation, and manufacturing planning to deliver accurate and efficient models.

In aerospace, NX CAD has an excellent capacity for advanced design, robust simulation tools, and manufacturing functions.

Software is vital in creating and manufacturing machinery and equipment in industrial automation. It promotes the high reliability and precision necessary for complicated manufacturing and equipment.

Strengths and weaknesses of NX CAD

Strengths of NX CAD

NX CAD is a reliable Infra CAD tool, famous for its superior modeler feature and its smooth integration among the design, analysis, and manufacturing functions. It is essential to work with complicated shapes and assemblies. NX CAD has numerous enhanced options for parametric and direct modeling, which makes it suitable for aerospace, automotive, and heavy industries. The software allows the handling of extensive assemblies without a problem.

In addition to the simulation and analysis capabilities, the software will enable designers to create accurate and efficient designs. Thirdly, NX CAD is highly flexible. It has APIs for programming-specific applications. The software efficiently works with other Siemens products, making it particularly valuable for large-scale, intricate projects.

Weaknesses of NX CAD

However, NX CAD has some disadvantages. NX CAD is costly to acquire and maintain, especially for Small and Medium-Sized enterprises. It has many features, and although this does assist in its operation, it vastly disadvantages anyone who may require more coaching within one. Moreover, the use of the software leads to operational capacity. Thus, it is typically combined with high-performance hardware, especially when working with large assemblies or complex modeling.

The particular user interface is changeable. However, it may be more perplexing than other CAD tools. In addition, the licensing models also present different problems. It could make it less available and sexy for organizations that per se do not require such functions.

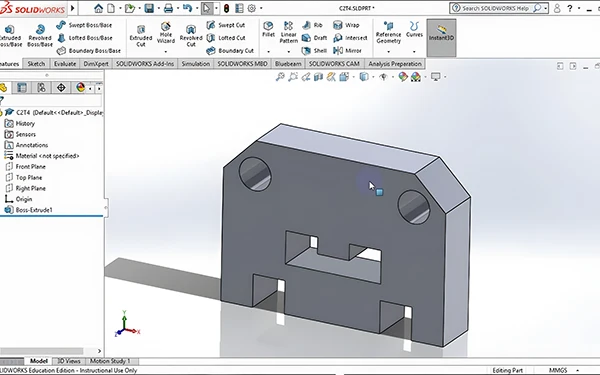

Overview of SolidWorks

SolidWorks is a 3D CAD program from the French company Dassault Systèmes. Its unique features include an interactive interface and excellent design functions, which are generally helpful to engineers, designers, and manufacturers. As solid modeling software, SolidWorks has many uses in modeling, Analysis, and product data management.

Core Capabilities of SolidWorks

All these essential elements are part of the SolidWorks application and make design comfortable and diverse. Its 3D modeling tools reinforce detailed models with the possibility of using parametric and direct modeling methods.

It is effective in the assembly design, where the assemblies by the organizations and relations and constraints of sections can be defined. It assists organizations to ensure the right attitudes and manners.

Accordingly, SolidWorks’s drafting and documentation tools are also professional. They allow the drafting of 2D drawings and documentation from 3D models, conforming to standard and explicit representations.

In addition, the applications also include integrated simulation packages for structural, thermal, and fluid systems. The users get FEA and many other analysis tools to validate and further assure the capabilities and toughness of the design.

Industry Applications

SolidWorks is helpful across various sectors as a powerful tool emphasizing design.

It is widely applicable in the automotive industry for modeling, simulation, and manufacturing planning to generate accurate vehicle parts and assemblies.

Furthermore, SolidWorks allows for more precise and efficient design in the aerospace industry. It works by providing superior simulation capabilities and complete compatibility with manufacturing phases.

In machinery manufacture, the software focuses on actual machinery and equipment to ensure they will accommodate the industrial requirements. It features some of the intricate aspects of accuracy and durability.

Strengths and Weaknesses of SolidWorks

Strengths of SolidWorks

SolidWorks by Dassault Systèmes is influential because of its economic cost, convenience in usage, and efficiency in design, among other things, especially for SMEs. This aspect is the easy-to-use and powerful 3D Modeling tools. The software offers robust capabilities for both parametric and direct modeling, making it versatile for various design needs. SolidWorks includes integrated simulation features such as Finite Element Analysis (FEA) and motion analysis, where users can verify and fine-tune their designs within the same environment.

Furthermore, there are a lot of add-ins and application compatibility with other software and tools. This enables the use of SolidWorks and the availability of solid communities and rich resources for learning.

Weaknesses of SolidWorks

Nevertheless, there are certain disadvantages of using SolidWorks. While SolidWorks is generally cost-effective compared to high-end CAD solutions, it may still be costly for small businesses or individual users. It requires a significant amount to pay for licenses, new versions, and modules. While the application may increase performance, completing large or complex assemblies may take longer than using CAE applications independently.

Overview of Creo

PTC’s Creo is a disaster, but the first of the Creo suite is Creo Parametric, which is quite powerful CAD software. This is due to its effective parametric and direct modeling, which has seen wide acceptance by engineers and designers.

Core Capabilities of Creo

Creo has a powerful primary suite of tools focused on design and engineering work. Both parametric and direct modeling approaches are possible by using its 3D modeling tools. This makes it an efficient instrument for designing intricate geometry types and detailed product forms.

It is vital for its precision and versatility in addressing intricate design requirements. In assembly design, however, Creo outperforms its competitors by offering sophisticated tools for assembly management. One can define the components’ relationships, constraints, and interactions, thereby enabling efficient control and adjustment of assembly structures.

Drafting and documentation allow for automated drafting of the objects into accurate 2D drawings from the 3D models to relevant industry standards.

However, Creo has sophisticated simulation tools. They include structural, thermal, and fluid analysis, finite element analysis (FEA), and test designs before manufacturing.

Industry Applications

Creo has proven especially useful in many industries due to its enhanced design functionality.

The discussion emphasizes its importance in the automotive industry for designing, modeling, and manufacturing parts and subsystems of automobiles.

Due to its stability and complete functionality, it plays a crucial role in this application. In the aerospace industry, Creo continues the design of aircraft parts and control subsystems. They comprise accurate modeling and analysis of instruments that affirm instrument integrity, stability, and efficiency.

In addition, it is versatile in mechanical and industrial engineering, particularly in producing machinery and production equipment. It concentrates on accuracy, power, and flexibility to address machinery and equipment requirements.

Strengths and Weaknesses of Creo

Creo is famous for incorporating great parametric and direct modeling ability, which is ideal for any engineering design. It performs well when dealing with large assemblies. It also boasts robust simulation and analysis tools like Finite Element Analysis (FEA). It incorporates computational fluid dynamics (CFD), which helps determine whether the designed product meets performance and safety levels. Further, the customization kit build-in and the other APIs within Creo enable the users to express how this software operates and the enterprise systems.

Nevertheless, the issues that appear in Creo are not diminished. The program’s pricing remains relatively high for companies depending on the subscription package, making it unrealistic for small to medium-sized businesses to adopt it. It also uses many resources and requires significant computing power for the best performance, which can be an issue for those operating in weak IT environments.

However, authorities’ licensing and the module system could confuse users. This is especially the case for those who decide on the application’s functional possibilities and organizational structure. These aspects can influence how much such practicality can benefit or disadvantage Creo for some organizations.

Making the Decision: Which CAD Software is Right for You?

Selecting the appropriate CAD application is a strategic decision that will profoundly influence engineering and design undertakings. Choosing the best depends on the type of work, the industry’s requirements, and the workers’ size and composition. Each CAD platform’s specific strengths, such as the capabilities of NX CAD, SolidWorks, and Creo, make it suitable for one situation over another. This information can help you make a wise decision based on the goals and needs of your project in an organization.

Key Factors to Consider Based on Project Type, Industry, and Team Size

- Project Type: One factor that may affect your decision is the nature and size of the project you are in. For high-accuracy projects, such as those in the aerospace or automobile industries, the large assemblies and complicated shapes might give NX CAD an edge. When compared to other complex CAD systems like Pro/Engineer, SolidWorks stands out for its user-friendly interface and adaptability to simpler projects. Relative to Pro/Engineer’s complex interface and capabilities, SolidWorks is usually opted for when work is more straightforward or involves more frequent changes. Parametric and direct modeling make Creo ideal for a project that requires detailed designing and, at the same time, frequent changes.

- Industry Requirements: The needs of various industries might vary, which dictates the type of CAD software one should use. For instance, the aerospace and defense sectors are known to use complex simulation and analysis solutions, in which NX CAD is useful. On the other hand, due to SolidWorks’ simplicity, there may be opportunities for the consumer products and electronics industries. It has a large inventory of designed components. Machinery and industrial equipment design brings Creo desirable product lifecycle management and integrated CAD tools.

- Team Size and Collaboration: Other factors that can affect your choice are your team’s size and the required level of integration. In large teams with many members working on intricate projects, NX CAD can be beneficial. It has good data management and assembly performance. This software has proper team performance features, which are particularly helpful for SW users involved in small production teams. Creo can benefit large projects carried out by big teams or small-scale projects done by small teams.

Recommendations for Different Engineering Scenarios

If your project has many assemblies and needs sophisticated simulation and evaluation, you should go for NX CAD. It is excellent in the large and tiny details. It is suitable for industries with high engineering specifications, such as the flying, car, and high-tech industries.

As for projects focusing on time-to-market and simplicity of usage, SolidWorks is one of the best. Its simple navigation, a wide variety of design templates, and ease-to-follow system make it ideal for consumer products and industrial machinery sectors. They require frequent product design modification.

Both Creo can be helpful if your project calls for a structure with some parametric/direct modeling and robust PLM integration. It is ideal for industries that involve complex design and require a sound method of asset management, such as the machinery, electronics, and automobile industries.

Conclusion

One must take the right CAD software to succeed in engineering design projects. In this case, three different CAD software packages can fit the project’s needs: NX CAD, SolidWorks, and Creo.

This is true when it comes to tool sets in drawing where NX CAD is less equipped than SolidWorks, but it trounces it when it comes to assemblies. It also conducts detailed calculations for sectors such as the aerospace industry and Automotive.

Solid work is relatively easy on this interface and has many robust design tools. Usage is concentrated where prototyping is essential, especially in small teams and industries focused primarily on consumer goods.

Creo can be described as an all-in-one solution that includes the most intuitive and flexible parametric and direct modeling engines and stable PLM integration. It applies to industries where detailed design involves the entire lifecycle of the component or assembly concerned.

When choosing the suitable CAD for a project, some factors to take into consideration are the type of project on hand and the needs of the project in question. Consequently, if engineers can establish the efficacy and productivity of each platform, they should be able to improve the overall performance of projects and technological development. In summary, NX CAD excels in complex assemblies and precision, SolidWorks offers simplicity and versatility, and Creo provides comprehensive parametric and direct modeling with robust PLM integration.