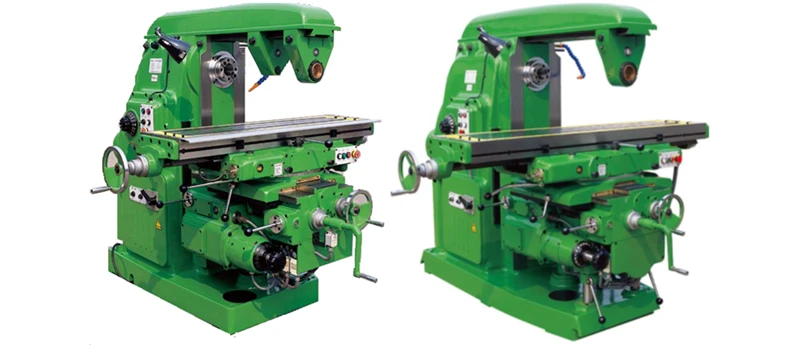

When analyzing the horizontal mill vs vertical mill, the main concern is the operational benefits.

What is a Horizontal Mill?

A horizontal mill is a type of milling machine in which the cutter is situated horizontally on the milling head. This sets it apart from vertical mills, where the spindles are positioned vertically. The spindle’s horizontal orientation brings about some gains when it comes to performing machining operations.

Key Features of a Horizontal Mill

Horizontal Spindle Orientation

The spindle in a horizontal mill is horizontal. Horizontal mills place the cutting tool on this specific axis. This design allows the cutting tool to move from side to side across the workpiece. As a result, it supports different types of cutting and styles.

Horizontal spindle enables lengthy and flat exercises or milling of large surfaces, enabling the tool to perform various tasks. Of these configurations, the horizontal spindle configuration poses several advantages, including stability and performance. It offers a robust setup, which is tremendously required in cutting processes involving large or bulky pieces.

This increased stability reduces vibrations and helps it cut more accurately, removing material and providing a fine surface finish. As a result, horizontal mills are suitable for any application where strength and accuracy are important in the production line, such as the automotive, aerospace, machinery, etc.

Table and Workpiece Movement

The spindle is mounted horizontally in a horizontal mill, and the tool cutter is secured to this horizontal spindle. This allows the cutting tool to be positioned side-to-side with the workpiece regarding cutting operations and approaches.

The justification for the spindle position being horizontal is to serve the purpose of operations requiring an elongated flat table or for TP milling extensive table areas. Horizontal spindle configuration exhibits several advantages, particularly in stability and performance.

It provides the support needed for extensive hacking operations involving large or bulky stock. The increased stiffness prevents vibrations and translations. This improvement ensures accurate and rapid machining of the material while providing a smooth finish. Consequently, horizontal mills are very useful where accurate and stringent tolerance in combination with rigorous usage is expected, such as in the automotive, aerospace, and heavy equipment industries.

Cutting Tools and Operations

In the horizontal mill, the worktable can be shifted right-left and forward-backwards. This movement enables the operator to maneuver the working table and the workpiece about the cutting tool, which is positioned horizontally.

The angular position of the table enables the operator to get the optimal position to make the cuts accurate and other intricate operations as needed without straining.

Furthermore, the construction of a horizontal mill guarantees clamping and securement of the workpiece with no hazard of slippage. This stability is essential in reducing vibration while cutting, especially when dealing with bulky articles. A secure setup also increases the repeatability of each cut to improve the performance of the overall machining jobs.

Chip Removal and Cooling

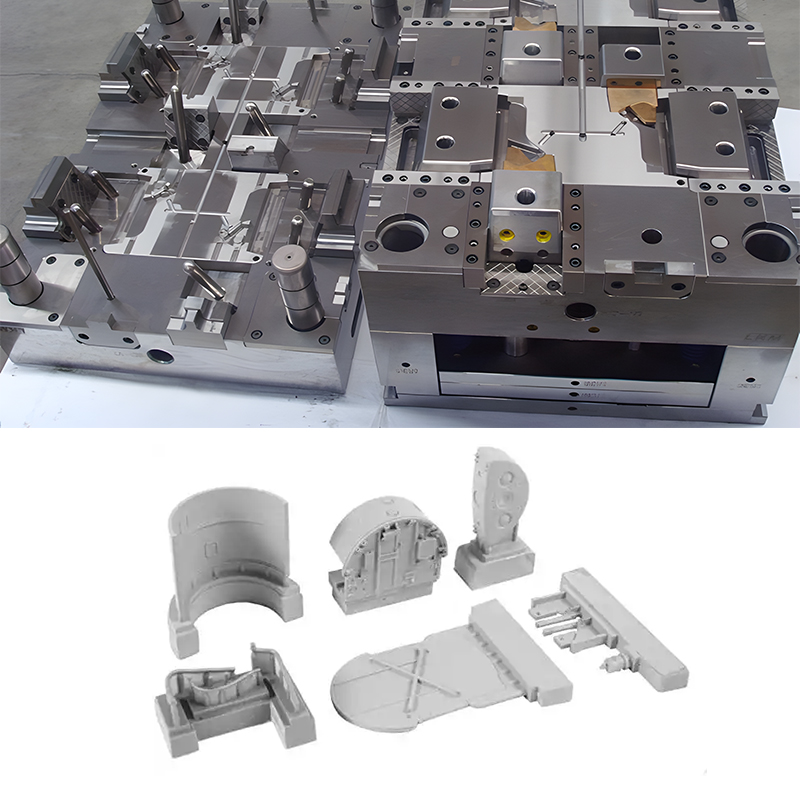

Horizontal mills use face mills, slab mills as well as side and face mills which are a requirement for specific cutting purposes. These tools are ideal for making wide cuts in one pass and are, therefore, more appropriate for some operations compared to vertical mills.

Another vital feature of horizontal mills is that it has high power to cut and remove large quantities of material in one go. This increased capacity translates to horizontal mills being in a better place to execute deep cuts, large surfaces, or complex contours.

Its application is possible in those industries where there is a need to work with oversized and heavyweight products.

Versatility and Setup

Horizontal mills exhibit great versatility and this means that in addition to being used for massive and deep cuts. The specific functions of these machines can be programmed for various usages such as slotting, drilling, and boring. It allows them to meet diverse manufacturing needs. Therefore, these components hold great value in many industries.

However, the arrangement of the horizontal mills is more compound than other kinds of mill machines. The process of making sure that the workpiece is correctly positioned and the clamping is secure involves having optimum desires for optimality.

While relatively simple, horizontal mills are ideal for applications that need greater precision and more taxing power to accomplish challenging tasks, owing to their enhanced functionalities.

Applications and Benefits Of Horizontal Mills

Heavy-Duty Machining

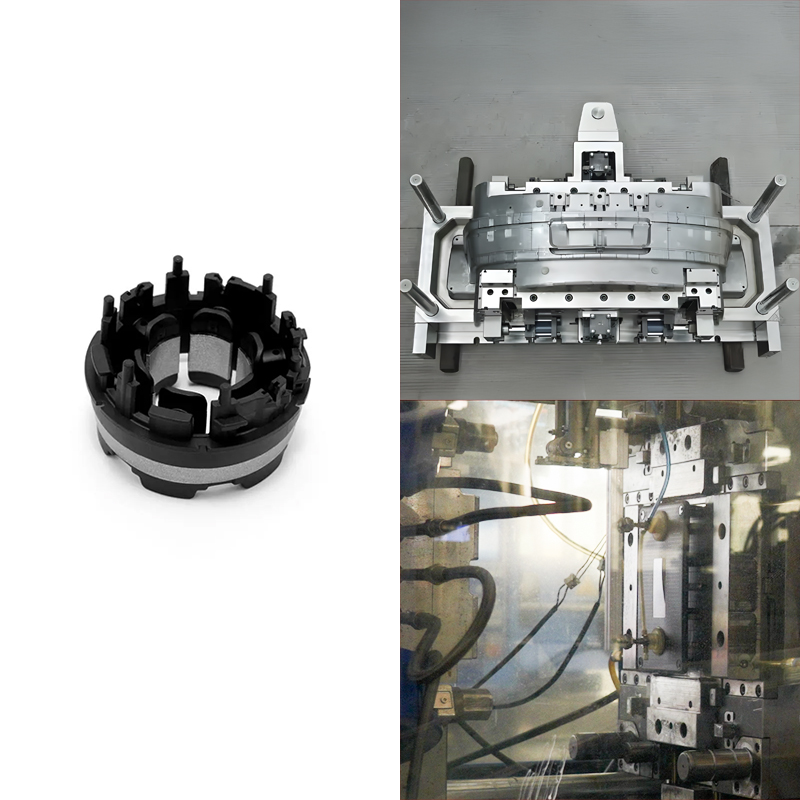

Horizontal mills are applied in situations where it is possible to work large volumes of large, heavy ‘chunks’ of material. They are most beneficial for car manufacturing factories, aviation companies, and industries that involve the production of large and heavy parts.

For instance, in the automobile industry, horizontal mills are employed to engage in components like engine blocks and transmission housing since it entails material reduction with tight tolerance needs.

As in the above example, these mills are applied in aerospace industries where large structural parts like wings, spars, and fuselages are required and where size and strength are factors in operation. Hence, horizontal mills become more critical in performing these functions since they are versatile enough to handle large-sized parts and machine them optimally.

Increased Stability and Accuracy

Horizontal mills are primarily classified based on the position of the spindle; there is a classification within this category; is the horizontal spindle type, which provides more stability during the cutting processes.

This stability is required, especially when dealing with complex or time-consuming operations of machines. It also helps to regulate motions and oscillations that may influence the quality of a product that is being manufactured on the machinery.

This is the case particularly where tight tolerances are called for or where small variations away from precision can significantly affect part dimensions.

Horizontal mills also feature a stable clamping arrangement and this is good when producing precision parts since the accuracy of the parts produced is high.

Enhanced Tool Life

Another benefit realized from horizontal mills is improved tool lifespan. As it is in other horizontal mills, this has a good method of conveying the chips out of the cutting zone so that there will not be congestion of chips, which leads to overheating of the tools.

These mills have high spindle speeds as well as efficient cooling systems that help in regulating temperatures during machining operations; thus, minimizing tool wear and tear.

Horizontal mills also enable a longer life of the tools by pressing the cutting tools and maintaining constant conditions of cutting. This is not only useful in terms of reducing the number of tool changes that may be necessary but is also very helpful in keeping down the total cost and ensuring that the tool performs stably and reliably over long periods of use.

What is a Vertical Mill?

A vertical mill is a type of milling machine in which the cutter is attached at a right angle to the spindle. Thus, this kind of design is different from the horizontal mills where the spindle of the machine is positioned horizontally. The configuration manner allows the cutting tool to slide between the up and down or the vertical direction, which is most desirable where fine detail and precision are preferred.

Key Features of a Vertical Mill

Vertical Spindle Orientation

The spindle is mounted vertically in a vertical mill, and the cutting tool is perpendicular to the workpiece. This design is ideal for exacting and cutting types of jobs where it is necessary to reach small, intricate parts with the tools.

The vertical spindle layout ensures that there is good sight and reach to the cutting area, which is ideal for precision and mini adjustments. It helps the operators exert fine-tuning and fine-cutting easily, thus improving the level of accuracy in milling.

Table and Workpiece Movement

In the case of a vertical mill, the work table only moves on the x and y axes. Meanwhile, the spindle moves on the axis in the perpendicular direction to the work table. This movement system aids in positioning the workpiece accurately with a cutting tool for effortless precision and accurate cutting of operations.

Positioning the vertical spindle in this manner is convenient for the movement and positioning of the workpiece, particularly where elaborate operations are required. It also conveniently allows accessibility of tiny pieces or parts, which may be needed in intricate operations, given that the spindle is vertical.

This setup is ideal in cases such as drilling, boring, and the machining of complicated shapes or forms. This makes the technology perfect for finishing intricate tasks that need precision since, due to the vertical arrangement, it takes less time to set up the machines than other formations.

Cutting Tools and Operations

As a vital tool, vertical mills are used in almost all vertical mills operating today and are designed for specific use, while other general cutting tools include drills and face mills.

These tools enable multiple functions, including slotting and even cutting multiple profiles and shapes, including making holes. Since vertical mills are closer to general-purpose machines in terms of tooling adaptability, such machines can be applied to any machining operation.

Vertical mills are employed, especially where the most extraordinary delicacy of work is required. They are best suited when used in applications such as model development, manufacturing small parts, or forming fragile structures, where precision is considered significant.

Vertical mills are essential in industries where high accuracy is desired, as these machines can perform exact operations.

Key Differences between Horizontal and Vertical Mills

| Feature | Horizontal Mill | Vertical Mill |

| Spindle Orientation | Horizontal | Vertical |

| Cutting Tools | Large, heavy-duty tools | Smaller, lighter tools |

| Applications | Heavy cutting, large workpieces | Precision work, smaller pieces |

| Setup and Operation | More complex requires more setup | Easier to set up and operate |

| Surface Finish | Generally rougher due to heavy cutting | Smoother due to lighter cutting |

| Cost | Higher due to complexity and size | Generally lower |

Milling Machine Performance Metrics

| Metric | Horizontal Mill | Vertical Mill |

| Maximum Cutting Depth | Up to 12 inches | Up to 6 inches |

| Table Size | 50 x 20 inches | 30 x 12 inches |

| Spindle Speed Range | 500 – 3000 RPM | 1000 – 5000 RPM |

| Power Output | 5 – 15 HP | 2 – 7.5 HP |

| Typical Applications | Heavy machining, large parts | Precision work, small parts |

Choosing the Right Mill

Understanding the specific requirements of the workpiece you intend to machine is crucial when deciding between a horizontal and vertical mill. Using a horizontal mill is preferable for thicker and larger stock because it can cope with the high forces needed during the cutting operation.

However, a vertical mill would be more suitable if your project entails many minor, intricate sections since it has better precision and control. Decisions regarding the choice of tools also depend on cutting precision. The vertical mills are used chiefly for highly accurate tasks and precise cutting due to the design of the equipment. This makes them suitable for uses where accurate or detailed cuts are required.

Thirdly, reflect upon the nature of the operations, with complex operations requiring more time. Horizontal mills are ideal for complicated operations that require several operations due to their versatility in a single setting. A vertical mill is usually easy to set and control due to its rigid simplicity and workability. This ease of use makes it cost-effective for simple operations.

Conclusion

When choosing between a horizontal mill and a vertical mill, you must consider what type of machining you will do. Horizontal mills offer rigidity and are suitable for high-duty applications, especially handling large and massive parts, making them essential in the automotive and aerospace industries.

On the other hand, vertical mills can perform precise and accurate work. They are highly suitable for fabricating small and complex workpieces. This makes them ideal for prototyping and other intricate components.

Knowing these differences and comparing the engineering data, you need to make the right decision for your project based on your expectations of optimizing performance and efficiency and achieving the desired results in your machining operations.