There are few Injection Molding Companies in Mexico that are star-rated to handle Injection molding. Injection molding involves forcing heated, molten material into a shaped mold cavity. This mold contains a cavity that corresponds to that of the desired part. After the plastic has cooled and solidified, the mold is opened, and the finished product is removed.

When we speak about injection molding, we can’t fail to mention Mexico. Mexico has become a major player in the global injection molding industry because of its skilled manpower and strategic geographic location. Its proximity to big markets in the U.S. and Canada, for example, has become a preferred destination for many injection molding companies. The country’s injection molding sector has grown tremendously supported by local and global manufacturers looking for efficient production. This is because injection molding is very useful in diverse sectors for example automotive industry. Mexico has a robust automotive assembly line relying heavily on injection-molded components, from dashboards to internal engine parts.

Below is a list of the Top 10-leading companies/manufacturers engaged in injection molding in Mexico.

MMI Engineered Solutions Inc.

MMI Engineered Solutions Inc. is in Monterrey, Mexico.

It is a subsidiary of a U.S.-based company in Saline, Michigan, that focuses on molding and tooling for small consumer products.

The company sits on 70,000 Square Feet and has over 42 years of offering custom-engineered solutions.

The primary operations performed by the company are:

- Custom engineering solutions,

- injection molding,

- rapid prototyping,

- product development,

- assembly services

Competitive edge: A competitive edge of MMI Engineered Solution is to distinguish itself through advanced composites and engineered Resins. They create innovative and high-performance plastic components. MMI offers its customers a one-stop shop through its services, from design to manufacturing.

Certifications:

IATF 16949 (Automotive Quality Management System).

2021 MMI-ES Won Processor of the Year Award from Plastics News

Notable Projects or Partnerships: Collaborated with Ford in the production of medical ventilator components to support the fight against COVID-19. Partnerships with several OEMs in the consumer products, medical, and automotive sectors.

Company Website: MMI Engineered Solutions Website

First Mold

First Mold is a well-known leading company in the injection molding industry. The company is an expert in precision engineering and high-quality plastic components.

Started in 2011, it is located in Guanajuato, México, with a subsidiary in Mexico factory spanning over 5,000 square meters.

The company operates internationally in over 30 countries, including Canada, France, and the U.S.

First Mold offers a range of products and services, namely:

- mold manufacturing,

- injection molding,

- CNC machining,

- rapid prototyping,

- die casting,

- production of custom plastic and metal parts.

Competitive advantage: One of First Mold’s distinguishing features is an all-inclusive manufacturing service, representing everything from concept to production.

This company provides services that are very important to sectors that deal with consumer goods, medical devices, aerospace, and automotive.

Partnership: First Mold has collaborated with major automotive and technology companies, such as BMW, Ford, Tesla, Huawei, and Porsche.

Vision and Mission statement: Their vision is to become a “Talent cradle” for the manufacturing industry. Its mission is to develop exceptional talent for itself and the manufacturing industry.

Company Website/Contact information: firstmold.com, email: [email protected].

Rocand Inc.

A world-leader manufacturing company with Headquarters in Quebec City, with additional facilities in Silao, Mexico. Other locations of operation are in France, Brazil, Germany, and South Africa. Rocand maintains a 4,128-square-meter manufacturing facility in Silao, equipped with cutting-edge technology like 5-axis CNC high-speed machines and injection presses for production.

Since it started its operations in 1996, it has offered the following products and services:

- Injection molding: High-tech plastic parts, Body, and exterior molds

- Extrusion blow molding: Electronic and electric parts, Small and general parts.

- MoldFlow simulation,

- EOAT(end-of-arm-tooling)

- engineering on tooling design

Rocand’s unique selling points include its integrated engineering, tooling, and production approach, allowing it to handle complex projects seamlessly.

Industry Certifications: ISO 9001:2015 for mold manufacturing, IATF 16949 for mass production, ensuring high-quality and reliable services.

Key Projects/Partnerships: the leading provider of automotive plastic parts, specializing in components such as air ducts for A/C systems.

Company Website/Contact Information: www.rocand.com; contact Mario Hernandez, New Business Director, at [email protected].

Platinum Tool Group

Situated in Saltillo-Ramos Arizpe, Mexico, Platinum Tool Group is a well-established company providing a reputable enterprise in the precision mold production industry. The company is headquartered in Ontario, Canada. It was founded in 1999 and lies on a 20,000-square-foot facility that provides an extensive range of technology and equipment.

. They are now a reliable partner for many different industries and offer a variety of products and services:

- Injection molds

- Compression molding

- CNC machining

- Mold design and engineering

- Project management

- Mold repairs

Competitive edge: Offers a competitive advantage with its expertise in producing high-precision molds, especially for optic surfaces and A1 diamond finishes. Alongside advanced CNC machining and CAM software (Delcam’s PowerMILL), superior quality and efficiency are guaranteed.

The company is ISO 9001:2015 certified.

Partnership|: It has collaborated with major automotive manufacturers like General Motors, Ford, Honda, Toyota, and Aston Martin. Platinum Tool Group and AarKel Tool & Die have formed a strategic alliance to expand their capacity in Canada and Mexico.

Company Website/Contact Information:

- Website: Platinum Tool Group

- Canada Phone: +1 (519) 737-1611

- Mexico Phone: +52 (844) 454-5700

Century Mold

Century Mold is a Manufacturing company situated in Chihuahua and Queretaro, Mexico. Founded in 1978, have been in operation for over 45 years. The company possesses a network of over 150 injection molding machines across various sites, demonstrating its impressive production capabilities. A comprehensive range of products and services provided by this company are:

- Precision manufacturing of plastic components for the automotive industry

- Radiator tanks

- HVAC components

- Wire channels

- Sunroof beams

- Reverse engineering

- Mold flow analysis

- Insert molding

- Multi-shot molding

Competitive edge: The company’s competitive edge lies in its strong focus on serving major OEMs. By offering added-value services like reverse engineering, they position themselves as an essential partner to the sector.

Collaborations: Century Mold’s has collaborated with several industries. Their components are used in cars made by leading automotive brands like Ford, GM, Toyota, and Nissan.

.Company Website: centurymold.com.

Fow Mould

FOW Mould, a high-tech company founded in 2009, is located in Taizhou, Zhejiang, China. With over 15 years of experience in the mold-making industry, FOW Mould has been operational since its establishment.

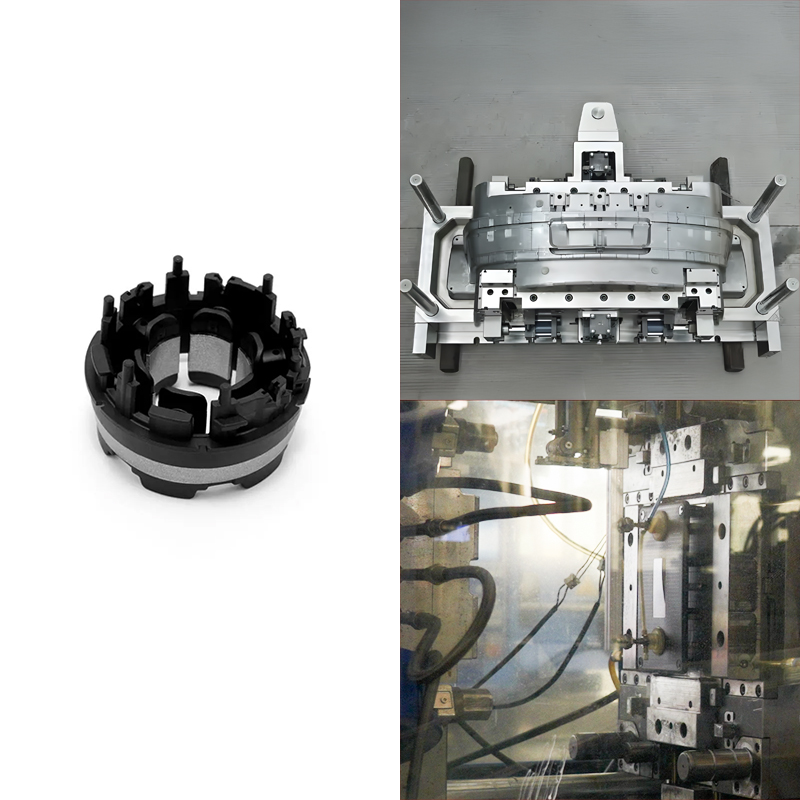

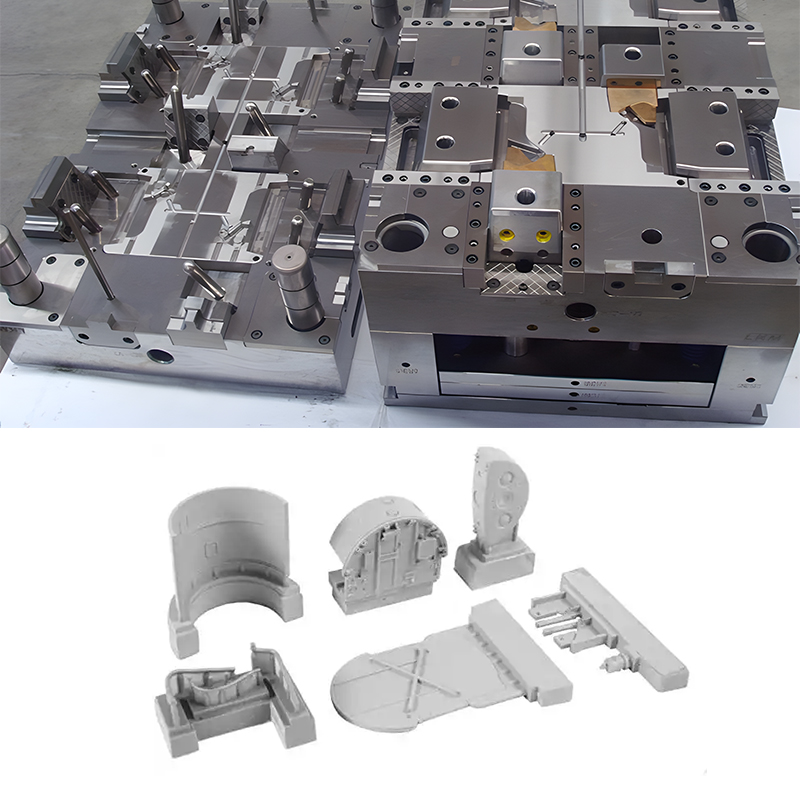

Fow Mould offers key products and services in:

- Design and manufacture of high-quality injection molds.

- injection molding services and CNC machining

Products:

- Buckets

- Storage Boxes

- Baby products

- Furniture

- Home appliances

- Automotive parts.

Selling points: FOW Mould has a unique selling point in offering cost-effective manufacturing solutions. They have a global presence, offering services to clients in Europe, America, and Russia. Their advanced technology, like 5-axis CNC machines and comprehensive quality control systems, ensures precision in mold-making

Partnerships: FOW Mould has exhibited at various trade shows and has established an international business network. They supply molds for enterprises such as home appliances and automotive, serving global clients.

Company Website:

- Website: fowmould.com

- Email: [email protected]

- Phone: +86-576-842882

Intran

Its Corporate headquarters are Located at 48 Sur Centenario #205, Civac, Jiutepec, Morelos, Mexico. It was founded in 1969 to cater to the needs of original equipment market demands (OEM). Initially, American Motors, Nissan, Volkswagen, Dina, and other OEMs were among the company’s clientele. Though a Medium-sized manufacturer, it has over 50 years of experience.

Key Products and Services:

- Custom plastic molded parts

- Electrical wire harnesses

- Fuel pump and sender assemblies

- Tube bending and forming

- Spot welding

- Sheet metal stamping

- Vacuum impregnation

- CNC machining

Selling points: Intran’s competitive edge lies in its ability to offer cutting-edge manufacturing technology, including CNC machines and vacuum impregnation equipment. Coupled with a low-cost labor force and proximity to the U.S., it ensures efficient logistics and competitive pricing.

Industry Certifications.

- ISO 9001-2008 (quality management certification).

- ISO/TS 16949 (automotive industry quality certification).

Notable Projects: Intran has a strong track record of working with leading brands in the automotive and industrial sectors, including T.I. Automotive, Freightliner, John Deere, UCI-Fram, Delphi, and Nissan.

Company Contact information:

- Website: www.intran.mx

- Phone (Mexico): +52 (777) 320 6798

- Phone (USA): (214) 202-2072

Azmex

Found at Nogales, Sonora, Mexico as its Manufacturing facility. But as a warehouse and shipping in Arizona, USA. Despite its medium size, Intran operates a fleet of 57 injection molding machines, showcasing its efficient production capacity. It was founded in 1982 and has operated as a maquiladora since 1999.

Intran offers a wide range of products and services to fulfill the needs of diverse sectors. Among their fundamental skills are:

- Injection molding

- Tool making

- Assembly

- Pad printing

- Sonic welding

- Hot foiling

- Proprietary phenolic connectors: design and production of unique phenolic connectors

Competitive advantage: Expertise in high-volume precision molding and extensive contract manufacturing services are two of Intran’s distinctive selling advantages. This company works with several industries, such as the industrial, automotive, and medical fields.

Industry Certifications: ISO 9001/2015, U.L. certification

Contact Website: azmexplastics.com.

Plastibell PSB Industries

Plastibell PSB Industries, is a leading global injection molding company, having manufacturing facilities in France, Mexico, the United States, and Poland, enabling them to serve customers worldwide. With over 500 employees and a wide range of services, Plastibell offers customized solutions to meet the diverse needs of its customers worldwide.

These include;

- Micro-injection: ideal for small and intricate components

- Over-molding: molding one plastic material onto another

- Insert molding: inserts metal, ceramic, or other components into plastic molds

- Cleanroom production: The company produces high-purity, contamination-free plastic components in cleanrooms designated as ISO 7 and ISO 8. This is particularly critical for medical and pharmaceutical applications.

Competitive edge: Plastibell’s distinctive selling characteristics are its proficiency with cleanroom production, use of bi-injection molding, and dedication to superior quality. This commitment to quality is demonstrated by its ISO 13485 accreditation. The company also offers integrated services such as assembly and decoration.

Accreditation: Plastibell is ISO 9001 and ISO 13485 certified, showing its dedication to high standards, particularly in healthcare applications.

Partnerships: There are some notable collaborations that Plastibell works with. Leading clients like Sanofi, Electrify, and Schneider showcasing their strong market presence.

Mission: Plastibell is committed to innovation, emphasizing sustainability and ethical values like safety and environmental responsibility.

Company Website: PSB Industries website

Providence Plastics

Plastibell is headquartered at Calle Geo #200, Parque Industrial Kalos Guadalupe, Guadalupe, Nuevo León, CP 67110, Mexico. Sales and project management for the U.S. market are handled from San Antonio, Texas.

Providence Plastics operates across multiple locations in North America, with a significant presence in Mexico, and has over 35 years of operation.

Key Products and Services offered to a variety of industries across North America

- thermoplastic injection molding:

- Tool design and fabrication:

- value-added operations

- Assemblies.

- Custom Solutions: tailoring its services to meet the specific needs

Competitive edge: Offers a competitive advantage with its ISO-certified quality system, competitive pricing achieved through lean manufacturing, and efficient management. High flexibility to quickly respond to customer needs and a strong focus on providing exceptional customer service and operational excellence.

Certifications: As an ISO 9001:2015 certified company, Providence Plastics is a trusted supplier for several prominent companies in North America.

Mission Statement: To use expertise and talent to generate sustainable economic stability by offering value-added thermoplastic injection molded products that exceed customer expectations.

Vision: Expand presence in Mexico and the U.S. with specialized value-added products that generate economic and social benefits.

Website and Contact Information:

- Website: Providence Plastics

- U.S. Sales: +1(210).870.9213

- Mexico Sales: +52(81).1599.2635