Springs are mechanical components that store and release energy as they undergo deformation under an applied force. Most springs are metallic and are available in different forms and types depending on the mechanical function. The most straightforward purpose of a spring is to store energy under a specific force and release it upon withdrawing the force and resuming its form.

This elastic property of springs is because the material can change its shape and size under force and return to its original size and shape upon removing force.

Mechanical Function of springs

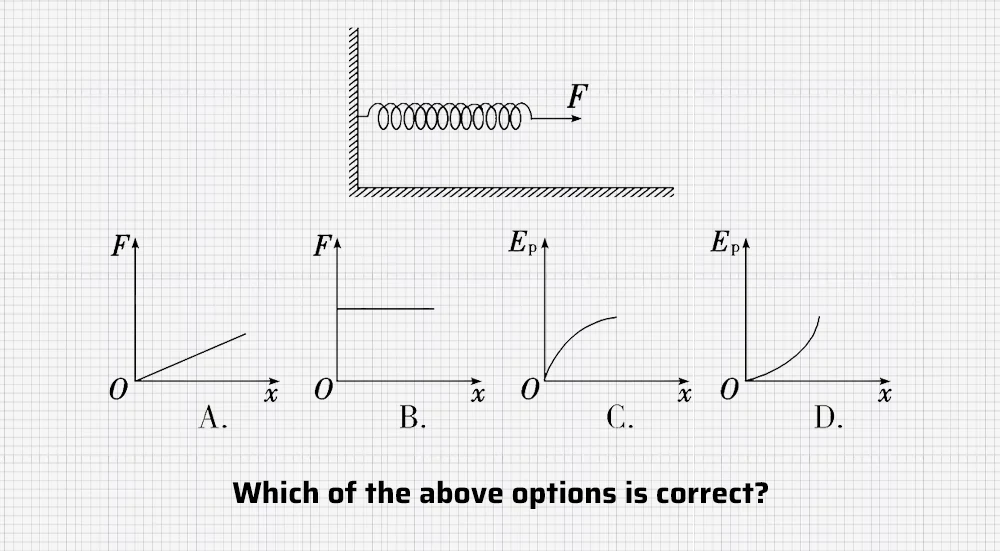

The mechanical role of springs is as a result of Hooke’s law. Under this law, the force on a spring correlates to displacement on the spring. The mathematical representation of Hooke’s law is:

F = kx,

F is the force with which a spring is compressed or stretched, k is the spring constant, and x is the displacement.

Springs can perform various functions.

First, springs can undergo compression. Springs deform on load application and exert an opposing force. Through compression, springs are helpful in shock absorbers and mattresses.

Second, the springs undergo extension, retracting under a pulling force. They build up potential energy and are useful in trampoline and garage doors. Springs also undergo torsion.

Helical springs, which can twist and coil to store energy, are found in mousetraps and clothespins. Some springs can demonstrate constant force. These springs provide a force continually on deflection, for example, in devices such as retractor seat belts.

Compression Springs: Design, Uses, and Variations

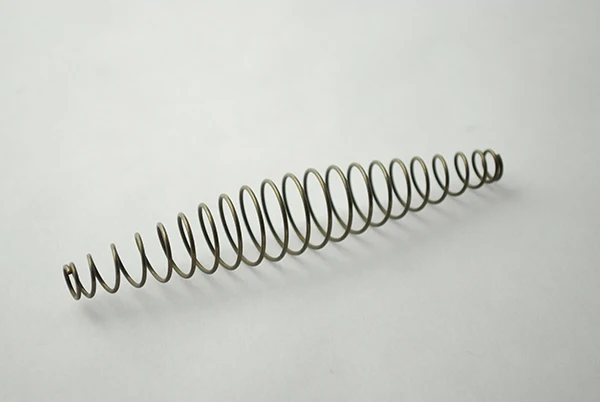

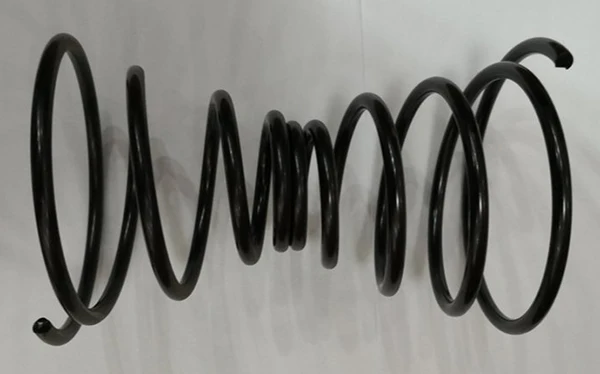

Compression springs are helical springs that bear compressive loads and store mechanical energy in the compression process. Typically made from round wire, they are coiled into a helix to compress under an applied force.

Depending on the application, these springs can be made from various materials, such as carbon steel, stainless steel, or specialty alloys, each offering different levels of elasticity, corrosion resistance, and fatigue strength. Compression springs are widely used in high-load environments like industrial machinery, precision instruments, and automotive suspensions, where material properties and spring geometry are critical for optimal performance.

The main objective of a compression spring is to resist the load and regain its original dimension upon releasing the load. This energy-storing property makes compression springs one of the most versatile types in many applications.

How Compression Springs Work

The operation of the compression springs starts by applying force. This force compacts the coils of the spring.

The force and the compression represent the potential energy of the spring. The extent of compression determines the force that the spring exerts back. The force is directly proportional to the compression, by Hooke’s Law. This means that the compression of the spring accumulates energy until the release of the load. Spring releases all its energy while removing the load and returning to its original shape and length.

The spring constant or stiffness or spring rate ( k ) defines the force necessary to compress the spring through a particular distance.

Elements of Compression Springs

Spring Diameters

A straight, helical compression spring is constructed from a wire of constant diameter, forming a cylindrical helix. To define the key diametrical dimensions of a compression spring, the following equations are used based on the cross-sectional view:

d=(Do-Di)/2,

D=(Do+Di)/2

In these equations, ddd represents the wire diameter in millimeters (mm), DiDiDi is the inner diameter of the spring (mm), DoDoDo is the outer diameter (mm), and DDD refers to the mean diameter (mm).

Spring Index (C)

The spring index (C) is the ratio of the mean coil diameter to the wire diameter and plays a crucial role in both the manufacturability and performance of the spring. Generally, a spring index between 4 and 12 is easy to manufacture, but an index of 6 to 9 is often preferred for cyclic loading applications, as it offers an optimal balance between flexibility and durability. Lower spring indexes (indicating tighter coils) result in stiffer springs, but they are more challenging to produce. In contrast, higher indexes make the spring more flexible, though this can lead to issues such as instability and buckling under load.

C=D/d

where C = spring index [unitless]

Spring Pitch (p)

The pitch is the distance between the two consecutive coils from the middle of the spring’s material when the spring is in the most relaxed state. This value is not the same as the distance between two consecutive coils. It is longer because it includes the radii of the two neighboring coils.

p=(Lf-3d)/Na

Where, p = pitch of the spring [mm], Lf = free length [mm], d = wire diameter [mm] and Na = number of active coils

Spring Constant

Stiffness, on the other hand, is an inherent property of a compression spring that dictates how it deforms when in contact with a force. It depends on the geometry and materials used to construct the waveguide.

k=dG/8C3Na

Where k = spring rate [N/mm] and G = shear modulus of elasticity of the wire material [N/mm2].

Common Uses of Compression Springs

Compressional springs are one of the most common types and are valuable in various industries and setups. They are commonly applicable in the automotive sector in car suspension. Here, they help minimize shock and offer stability. They also apply to engine valves, maintaining tension for efficient functioning. Compression springs are extensively helpful in the aerospace industry, especially in landing gears, where they enable ease of folding and setting up of the gears.

In various control systems, they are critical in controlling forces and motions. These springs in syringes, inhalers, and prosthetic limbs control movement and provide constant force. Compression springs are vital in many consumer goods, such as writing instruments with retractable parts. They help mattresses bear the body’s weight and provide comfortable support.

Moreover, machines, it has applications in clutches, valves, and actuators of industrial equipment to regulate force and motion properly.

Different Types of Compression Springs

Compression springs are available in various shapes and designs to suit applications. Some of the common types include:

Cylindrical Compression Springs

These are typical in design, with the coil having a constant circumference. The switch’s simple construction and high efficiency make it helpful in numerous applications.

Conical Compression Springs

These springs are cylindrical, but their coils are conical. The diameter reduces from one end of the spring to the other. They are helpful in applications where space is a luxury, such as battery contacts or telescopic structures.

Barrel Compression Springs

Barrel Compression Springs are cylindrical, with a larger diameter in the center and a smaller diameter towards the two ends. These designs offer a more remarkable ability to prevent buckling and thus are more appropriate for applications in which lateral stability is needed, such as vibration isolators.

Hourglass Compression Springs

Like barrel springs, hourglass springs have the largest diameter at the terminating end and the smallest at the midspan of the spring. They provide stability and anti-buckling and effectively resist alternating lateral loads the spring may face.

Variable Pitch Compression Springs

These springs feature varying coil densities along their length. This design increases the spring’s stiffness under compression, making it suitable for applications involving variable force, like load support systems.

Nested Compression Springs

Sometimes, in some applications, several compression springs combine to raise their load or provide a particular force pattern. This configuration is standard for applications requiring more than a single spring, primarily in high-load circumstances.

Extension Springs: Mechanics, Applications, and Customization

Extension springs are designed to resist a tensile or pulling force, in contrast to compression springs, which resist compressive forces. When an external force stretches the spring, mechanical energy is stored within the material. The amount of force required to extend the spring follows Hooke’s Law, meaning the force is proportional to the displacement.

Extension springs have hooks, loops, or other attachment methods at each end, facilitating their integration into mechanical systems. Widely used in dynamic applications such as automotive brake systems and garage door mechanisms, they maintain tension and restore components to their original positions upon release.

On removal of the force, the spring releases energy, causing the spring to contract back to its original length. The force required to extend the spring depends on Hooke’s Law. Extension springs typically have hooks, loops, or other attachment methods at each end, allowing them to connect to different system components. The resulting tension in extending the spring helps maintain a stable connection between these components.

Applications of Extension Springs

Extension springs are used extensively in many areas that involve tension or pulling force within the equipment. These springs perform a wide range of functions in automotive construction. In brake assemblies, they are responsible for returning the brake pedal to its initial state after depressing. In trunks or hoods, they contribute to the opening and closing operations.

Extension springs are useful in household appliances like washing machines and dishwashers, as they assist in controlling the movement of doors and lids.

Furthermore, some of the other applications of extension springs include overhead garage doors, which act against the door’s weight. This makes it easier to lift the door manually or with the assistance of an opener.

They are also vital to toys and tools, for example, in the retractable key rings and clamping hand tools by which tension occurs. Extension springs are mandatory in trampolines as they stretch and contract as the trampoline users jump.

Torsion Springs: Functionality, Types, and Industrial Uses

Torsion springs are spiral and have a curving nature, either clockwise or anticlockwise, in an attempt to store and recover mechanical energy. This type of springs, in contrast to compression and extension springs, are not under linear force compression or extension force but rather rotational or angular forces.

The terminals of the spring are usually in contact with other parts. Turning the central part of the spring, the spring turns to coil up, and therefore, it can store energy. Upon releasing the force, the potential energy causes the spring to return to its position and offers the torque necessary to rotate the other parts.

How Torsion Springs Store and Release Energy

Torsion springs operate on a force in the form of torque, which causes the spring to rotate. The torque directly correlates to the angle of twist and the spring constant, as well as the wire diameter and coil geometry. When a torsion spring is twisted, it stores energy as elastic potential energy within the spring’s material. Releasing the load translates energy into kinetic energy, whereby the spring can apply a force to the rest of the components that help return the body to its original position.

This mechanism is widely applicable for different applications, such as offering limited rotation, concurrently guaranteeing the specific orientation of components, or creating tension in automatic systems.

Common Industrial Applications of Torsion Springs

Torsion springs are crucial components in different industries and commerce that require controlling rotational force. In automotive applications, they are essential in trunk lids, hood hinges, and tailgates to control the opening and closing movements. Besides, torsion springs are helpful in steering, where they help to get the steering wheel back to its center position, as will be seen later.

In aerospace, they are essential in aircraft control volume parts like the ailerons and flaps to facilitate the return force and also actual alignment. Torsion springs also help support the deployment and retraction of landing gear mechanisms so that they can operate seamlessly and without a hitch.

Torsion springs are proper in industrial machinery such as clutches, levers, and actuators to deliver the force necessary to function mechanical components and retain tension. They are also helpful in doors and window frameworks like garage doors and industrial roll-up doors, which help counterbalance the weight of the door and, hence, ease its operation.

Electrical devices are vital in maintaining contact pressure for switches and circuit breakers – they make the switch return to the default state after it has been set to work. Besides, these springs are helpful in hand tools such as pliers, clamps, and ratchets, which hold the moving parts into position and provide the necessary force to move the hand tool back to its initial position after use.

Types of Torsion Springs

Torsion springs come in various types, each suited to specific applications:

Single Torsion Springs

These are the most popular springs since they offer rotational force in one specific direction. They apply when the spring should turn and come back in a single direction.

Double Torsion Springs

Double torsion springs have two coils in opposite directions and are connected by a center section. This design enables a higher degree of torque and flexibility.

Custom Torsion Springs

Torsion springs can, therefore, take different forms, including wire diameter, number of coils, length of legs, and kind of material. Custom gasket designs may be necessary in cases where the application has specific available space or force application needs.

Leaf Springs: Structure, Advantages, and Automotive Applications

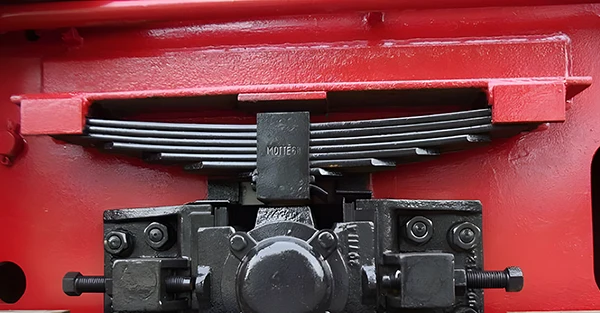

A leaf spring is a type of suspension component commonly manufactured by stacking multiple thin, flexible metal strips parallel to one another, creating a semi-elliptical shape. The fabrication materials are usually high-tensile steel. The two ends of the leaf spring are either invented directly for the vehicle’s framework or via shackles to enable the spring to bounce and endure impacts. Springs are manufactured in layers so that they can bear big loads with appropriate weight distribution and stress along the length of the spring.

Advantages of Leaf Springs

The benefits of leaf springs lie in their widespread application in many vehicles, particularly heavy-duty trucks and off-road vehicles. The multi-layered design of the leaf spring allows for effective load distribution along its length, improving stability and load-bearing capacity. This design reduces stress concentrations and helps to evenly distribute forces, enhancing durability and extending the lifespan of the suspension system.

Due to their minimal parts and design, the construction of leaf springs is basic and easy to implement; few components move, making the springs have a longer life span than most other suspension systems available. They are also economical because they have relatively simple structures and are easily manufactured. They suit large and bulky vehicle types well.

The rear and front wheels suspension by leaf springs enables the system to support massive loads, which helps carry loads like trailers and trucks without affecting stability. Their design maintains the necessary balance of stiffness and flexibility. It contributes to the vehicle’s stability, which is essential for handling and safety, and the ride height stability under load.

Automotive Applications of Leaf Springs

Spring leaves are essential components of suspension systems that are functional in most automobiles. In trucks, trailers, and other commercial vehicles, the leaf spring system is the most widely known form of suspension system. The springs support the load while keeping the vehicle in balance even when it is heavily laden. Due to the good construction, they can take and minimize road vibrations, hence offering a smooth ride due to constant contact between tires and the road.

Moreover, as the leaf spring only undergoes minor wear and tear and experience, it is perfect for rough terrain and heavily used vehicles. Even today, leaf springs are still valuable for off-road vehicles and some older models of passenger cars. They can support considerable weight while simultaneously maintaining ride height and stability, which are essential for safety and comfort.

Conclusion

Knowledge about various types of springs is crucial in deciding which spring is suitable for use. Each one has different kinds of mechanics, and they possess different functions, making them ideal for numerous industrial, automobile, and household applications. Compression springs are more valuable because they store c energy, while extension springs are critical in tension assemblies. Torsion springs allow rotation force, and the leaf springs provide lasting support in heavy loads applications.

Understanding the types of springs is helpful for engineers and designers of mechanical systems to enhance performance, durability, safety factors, and reliability.