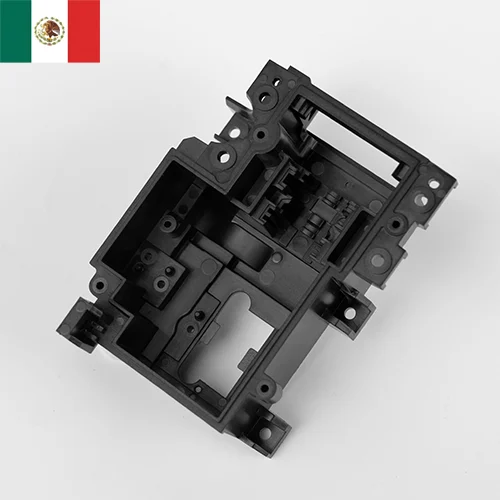

World Class Mold Manufacturing and Injection Molding Services From Mexico

Our facility offers world-wide mold manufacturing and injection services with global quality standards and cost advantages

Global Quality Standards

Competitive Pricing

Efficient Global Shipping

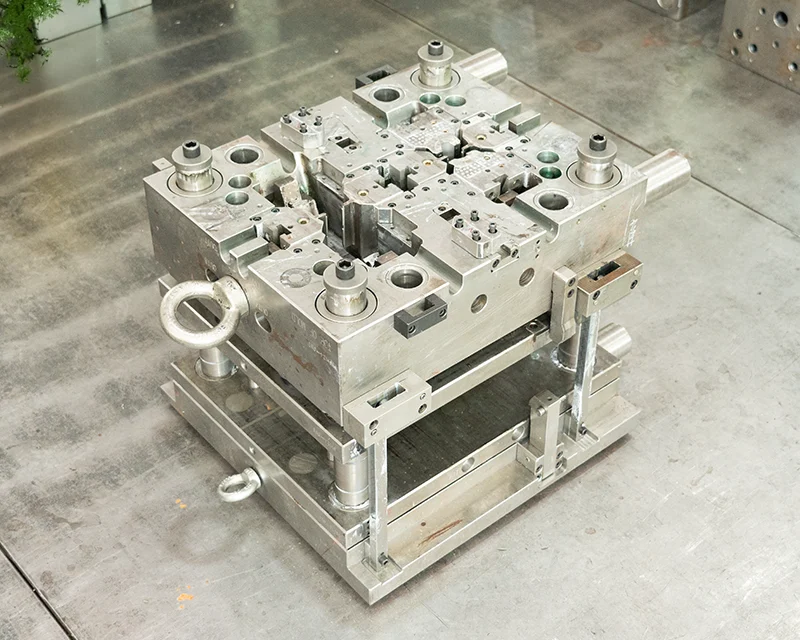

Overview of Our Mexico Facility

Our Silao, Mexico facility is a hub for high-quality mold manufacturing, particularly in rapid tooling and injection molding, leveraging advanced technology inspired by top manufacturing practices from China. We specialize in rapid prototype molds, high-volume production molds, and complex two-shot (double-injection) molds, fully equipped to handle a variety of manufacturing needs.

Our primary clientele extends beyond—spanning the U.S., Canada, and Europe. With our strong logistics network, we deliver end-to-end solutions across North America and Europe, ensuring quality and timely delivery to meet diverse market demands.

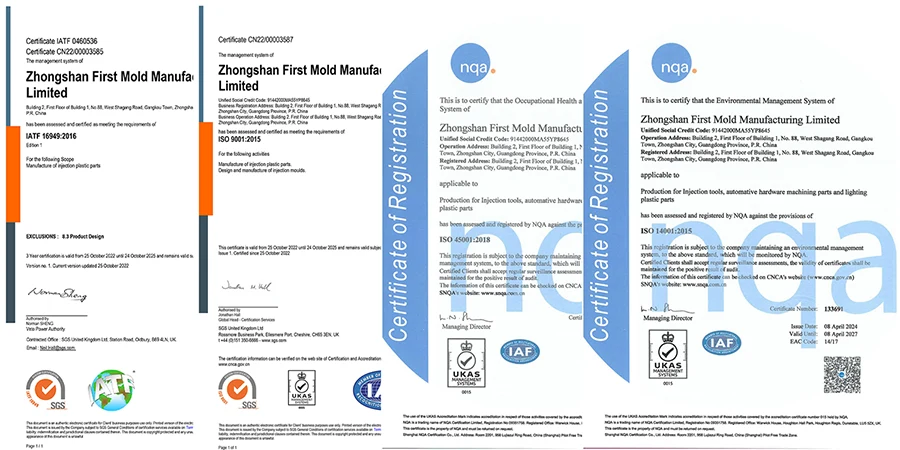

- IATF 16949: 2016

- ISO 9001: 2015

- IATF 16949: 2016

- ISO 9001: 2015

Client We Served

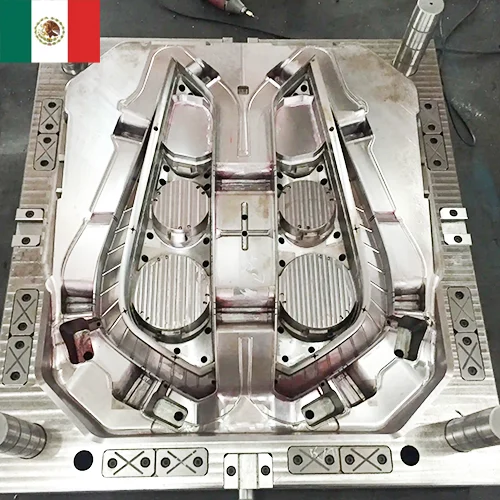

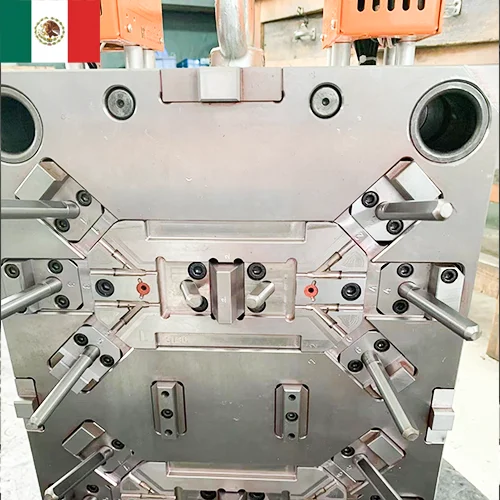

Customized and End-to-end Mold & Injection Services

Rapid tooling, production tooling, two-shot mold, hot runner mold, etc.

Standard molding, Two-shot molding, overmolding, insert molding, etc.

Comprehensive Mold and Molding Solutions Across Industries

At our Mexico facility, we bridge the worlds of innovation and precision across multiple industries. Every mold, every part, every intricate detail is crafted to exceed the rigorous demands of automotive engineering, the exacting standards of medical devices, the sophistication of home appliances, and the meticulous specifications of optical components. We adapt, innovate, and deliver exceptional results.

Automotive Mold

Dashboard Panels, Air Vent Frames, Bumper Components, Gear Shifter Housings, etc.

Medical Device Molds

Syringe Bodies, Surgical Tool Handles, IV Connectors, Test Kit Casings, etc.

Optical Precision Molds

Camera Lens Frames, Light Guides, Protective Lens Covers, Sensor Housings, etc.

Consumer Electronics Molds

Phone Casings, Speaker Enclosures, Remote Control Housings, Charging Dock Frames, etc.

Automotive Parts

Dashboard Panels, Dashboard Bezels, Door Panels, Airbag Covers, etc.

Medical Device Parts

Insulin Syringe Housings, Blood Test Casings, IV Line Components, Dialysis Cartridge Casings

Optical Parts

Display Screen Bezels, Light Diffusers, Lens Holders, Protective Goggles Frames, etc.

Consumer Electronics Parts

Headphone Casings, Charging Port Covers, Game Controller Shells, Laptop Bezels, etc.

Why Choose Mexico for Your Molding and Molding Needs?

Mexico has become a strategic location for mold manufacturing and injection molding. With proximity to major markets, competitive labor costs, and robust logistics, Mexico is an ideal choice for efficient and reliable manufacturing.

Cost-Effective Production

Mexico offers highly competitive manufacturing costs.

Trade Agreements

Mexico has extensive trade agreements, including USMCA.

Reduced Lead Times

Mexico’s proximity to key regions allows for faster lead times.

Shape Your Future with a Click

Experience the Difference: Partnering with First Mold Mexico

What You Gain by Partnering with First Mold’s Mexico Facility?

Weekly Updates to Keep Clients Informed

- Every project is overseen by a dedicated manager, following a strict timeline.

- Clients receive weekly progress reports and mold photos to stay up-to-date.

- Online trial run videos are available, allowing clients to see the mold in action.

Quality Control at Every Stage to Prevent Production Issues

- Each stage—material receipt, processing, and final molding—undergoes thorough inspection to identify issues early.

- Each project includes a complete quality report, ensuring full traceability.

- All steel is imported from Germany or the USA, with original certificates provided.

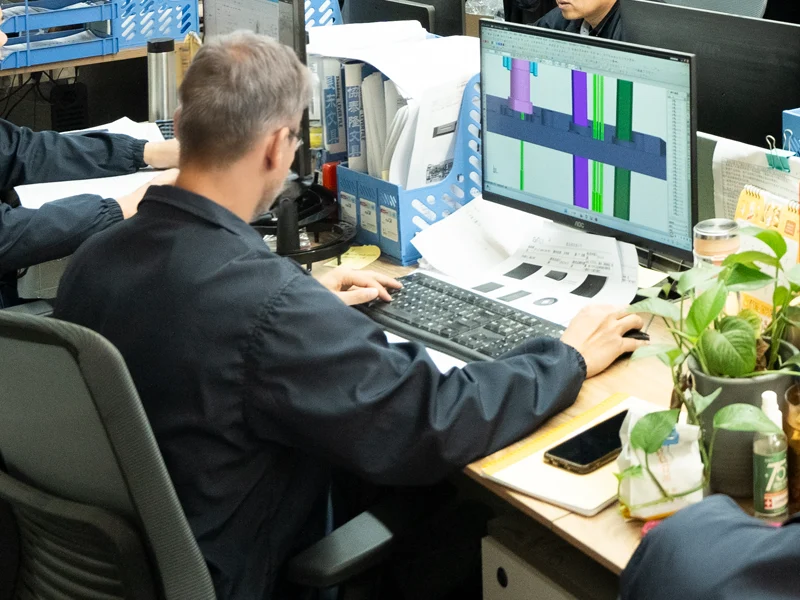

Rigorous Design Process, 96% Success in First Trial Production

- We preemptively identify potential issues by analyzing material properties, wall thickness, deformation, and gate position feasibility.

- We maintain close communication to understand client requirements, such as parting line placement and surface appearance needs.

- A strict checklist-driven review is conducted, with structural discussions before design, self-checks by designers, and a final review with the manufacturing team.

A Streamlined Manufacturing Process for Worry-Free Production

Craft Perfection with a Click

Inside Our Mexico Facility

Our Mexico facility is equipped with advanced machinery and staffed by experienced professionals, dedicated to delivering high-quality molds and injection-molded parts. With a streamlined layout and state-of-the-art technology, our facility is optimized for efficiency and precision.

High-Quality Material Options

Quality is non-negotiable. We source the finest materials from trusted suppliers, using rigorous standards to ensure that each mold and component can withstand demanding conditions and deliver exceptional performance.

| Tool Steel | Stainless Steel |

|---|---|

| Carbon Steel | Aluminum |

| Pre-Hardened Steel | High-Speed Steel |

| Zinc Alloys | Beryllium Copper |

We also serve local manufacturing businesses Across Mexico

Our Mexico facility, located in Silao, Guanajuato, is strategically placed to provide top-quality mold manufacturing and injection molding services across Mexico’s most vital industrial hubs and beyond. From Toluca to Puebla, from Monterrey to Tijuana, we bring precision and reliability to clients located throughout these key cities. Our reach extends to major markets, ensuring that whether you’re in Mexicali or Querétaro, our team is ready to meet your manufacturing needs with unparalleled expertise.

Our central location in Silao allows for efficient, rapid response to client demands in Guadalajara, Ciudad Juárez, Hermosillo, and more. We understand the unique requirements of each region, adapting our processes to seamlessly serve clients in Reynosa, Matamoros, Saltillo, and Apodaca. By leveraging Mexico’s robust logistics infrastructure, we deliver products faster and more cost-effectively to North American, European, and international markets.