PVC (Polyvinyl chloride) Injection Molding

Durability, chemical resistance and versatility make many industrial designs possible with PVC

- An economical option for producing high-volume, complex shapes

- Available in rigid or flexible forms

- A preferred material for electrical housings and automotive components

PVC Product Manufacturing Services From Professional Plants

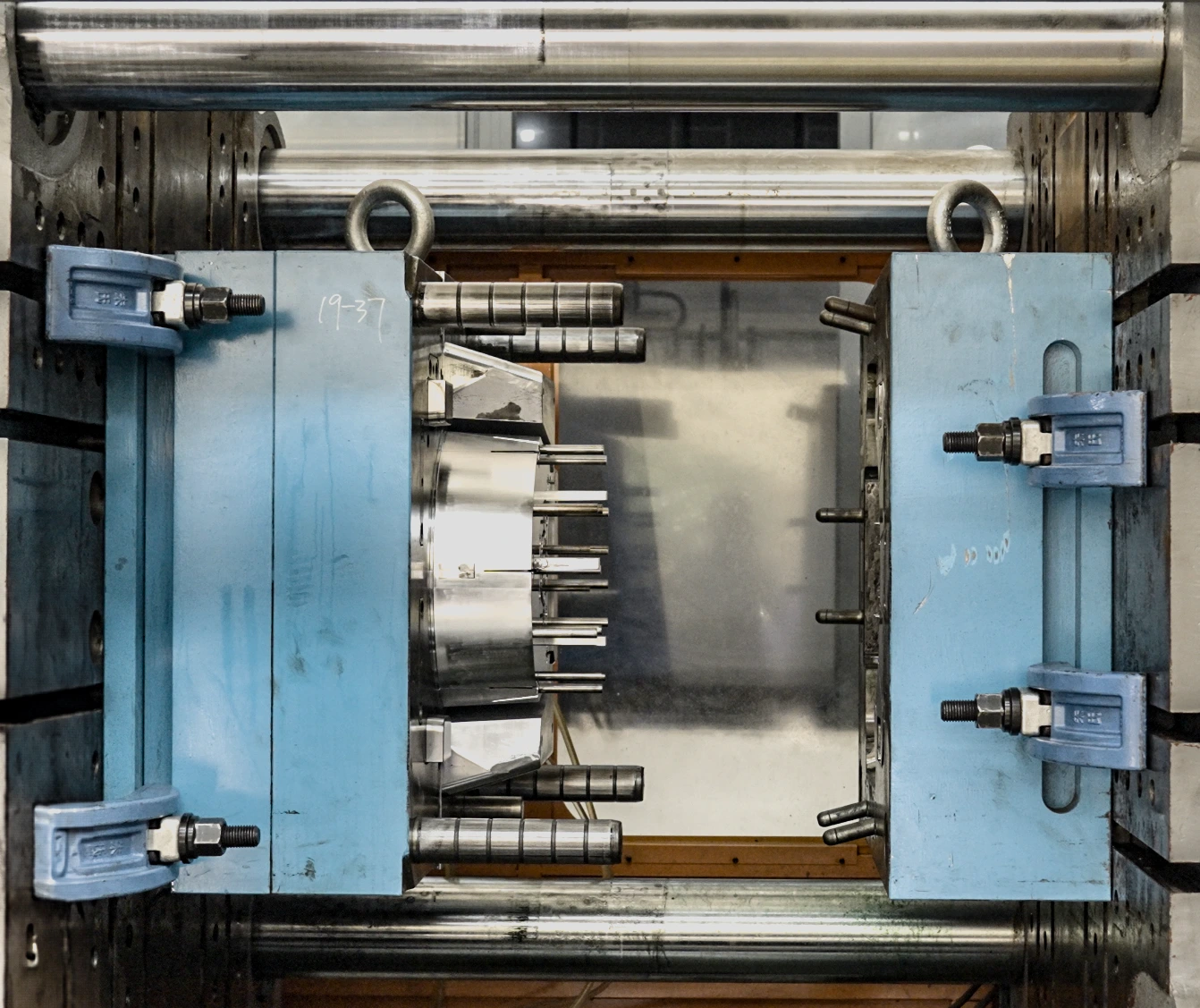

For many years, FirstMold has been providing high-quality production molds for European and American customers, including automotive molds, medical molds, electrical molds, two-color molds, thin-wall molds, and various other custom injection molds. The core of PVC product quality lies in mold design, and we have accumulated extensive experience in mold design, development, and production, ensuring strict control over product quality for our clients.

Applications of PVC Injection Molding

PVC, with its flexibility and comfort, aesthetic appeal, and affordability, has brought numerous conveniences to people’s lives. FirstMold has applied it across multiple industries in past cases.

Automotive & EV

- Dashboard Vent Slats

- Electrical Grommets

- Headlight Washer Jets

- Gear Shift Knobs

- Door Lock Buttons

- Window Switch Bezels

- Instrument Cluster Housings

Consumer Electronic

- USB Flash Drive Cases

- Tablet Back Covers

- Wireless Router Bodies

- Portable Charger Casings

- Smartphone Stand Bases

- Headphone Adjustment Sliders

- Camera Battery Doors

Outdoor Gears

- Bycicle light housings and mudguards

- Ski goggle frames

- Outdoor equipment handles

- Swimming goggles

- Sports Equipment Knobs

- Kayak Seat Adjusters

- Fitness Band Casings

Personal Care

- Mascara Tubes

- Lotion Pump Heads

- Dental Floss Dispensers

- Lipstick Mechanisms

- Eyeliner Sharpeners

- Hair Comb Teeth

- Shaving Razor Handles

Traditionally, PVC is often associated with its use in construction materials and piping. However, the reality is that PVC’s application in injection molding is quite widespread.

PP

PE

PC

PVC

ABS

PA

POM

PBT

PMMA

PEEK

PVC Injection Molding Capabilities At FirstMold

Our capabilities in PVC injection molding are undeniable and are primarily demonstrated in the following areas:

Equipment:

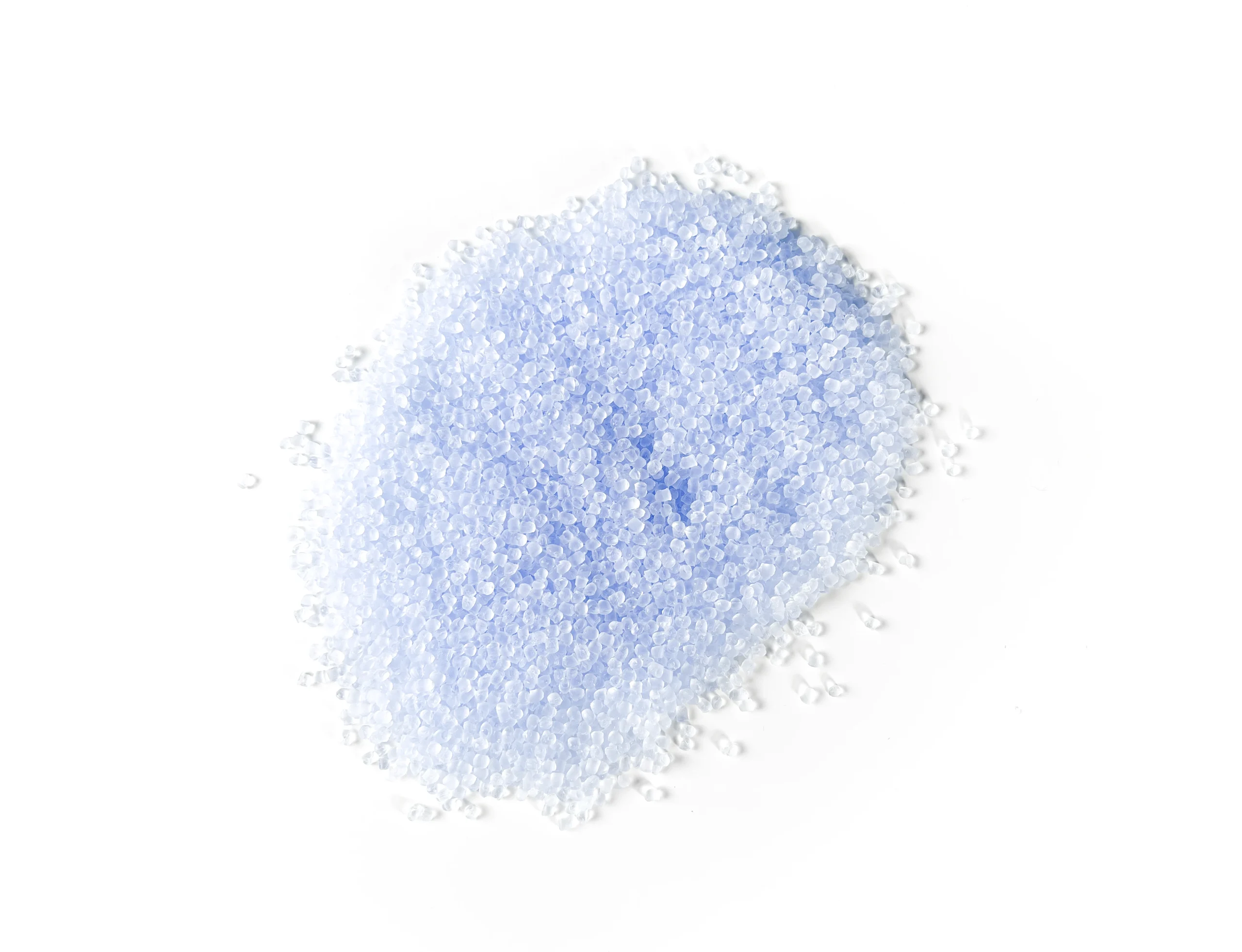

Material Expertise:

Molding Technology:

Design Support:

Customization:

Quality Assurance:

High Volume Production:

Innovative Solutions:

Speed to Market

Our PVC injection molding is based on our strong rapid tooling and production tooling technology, which allows us to meet delivery dates and get your products to market as quickly as possible.

Color and Finish Options

FirstMold’s color control of PVC products is unique and does not tolerate color differences. We also offer a wide range of product finishes to make your products perfect.

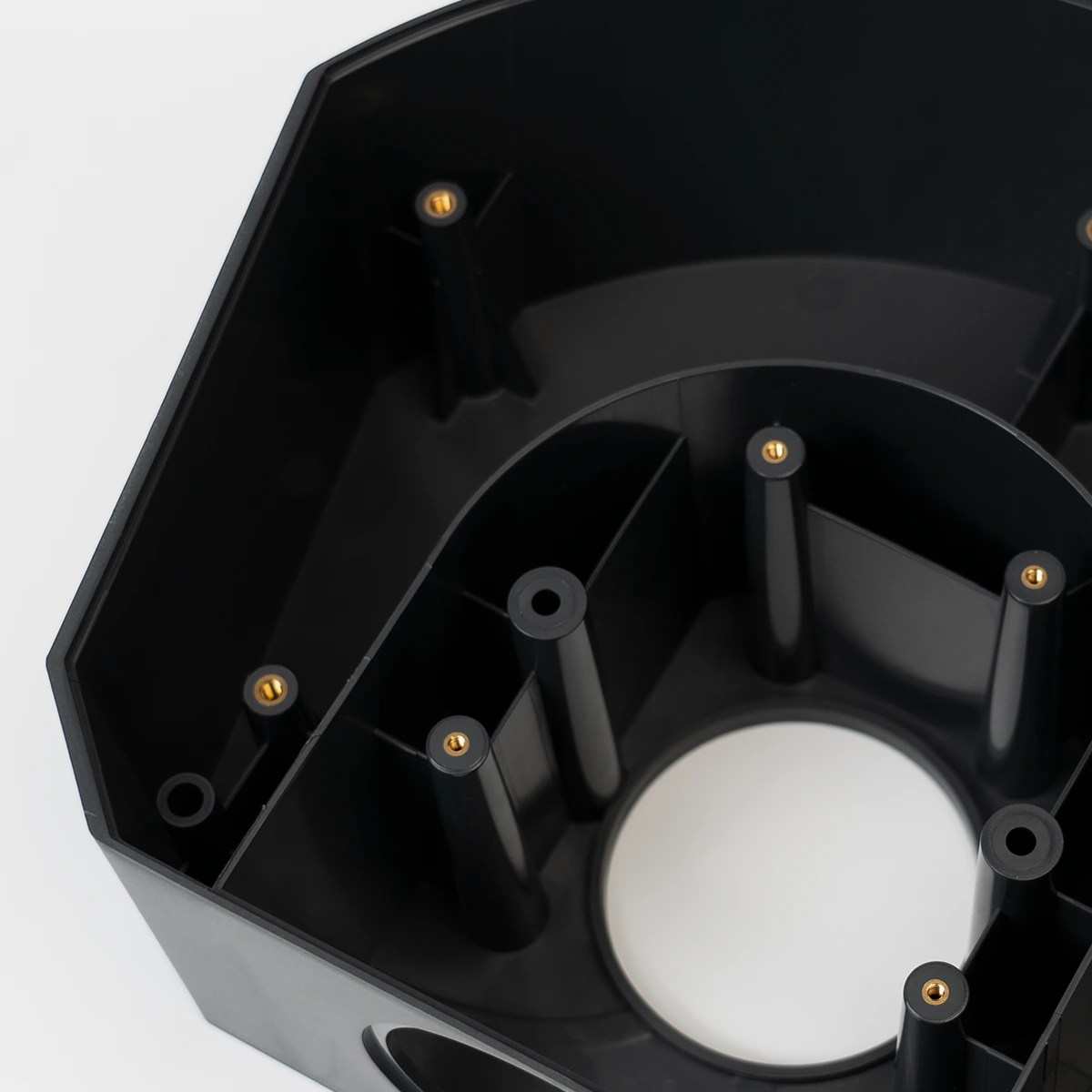

Complex Part Production

Complex PVC parts rely on experienced mold design. Our team of at least 20 mold designers with more than 10 years of experience work together with our processing and injection molding departments to produce each complex part.