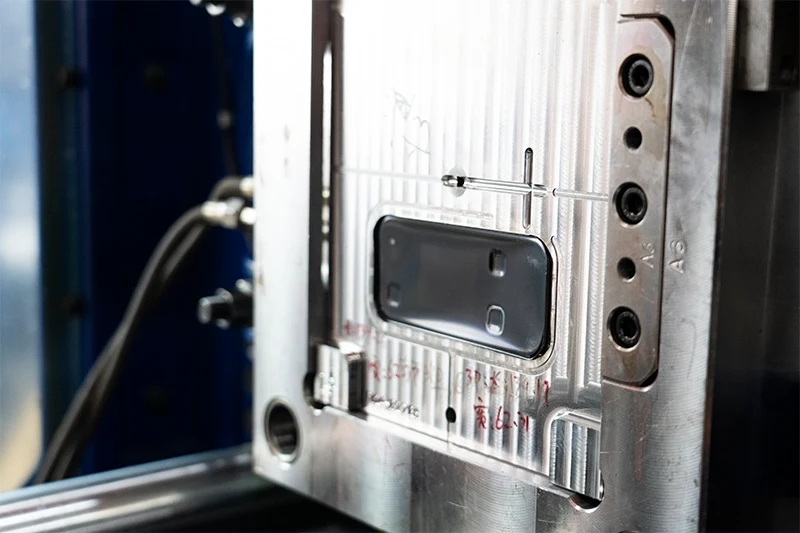

Injection molding in consumer electronics is a significant manufacturing process that is critical in the production of consumer products. This technique has transformed plastics production by allowing for the large-scale creation of complex plastic parts, such as those found in electronics and kitchen appliances. In the field of consumer electronics, injection molding can create connectors, phone casings, and internal structural parts.

Significantly, manufacturers can produce large volumes of parts without compromising on quality. This is especially critical for electronics, which require high tolerances and durability. Using Injection molding, designers can easily design and create complex, ergonomic products that enhance the user experience.

By leveraging such benefits, First Mold produces high-precision plastic components for the consumer electronics sector by utilizing its vast engineering experience and state-of-the-art design skills. In close collaboration with our clients, we ensure that custom hues, finishes, and textures adhere to their design guidelines. Our dedication to quality and creativity enables us to assist our clients’ visions from the initial concept to the finished product. You can find out more about our services through the following link. https://firstmold.com/industries/consumer-electronic/

The Role of Injection Molding in Consumer Electronics

Almost every consumer electronic item made today involves a particular aspect of injection molding techniques.

In the manufacture of consumer products, injection molding cannot be downplayed easily. Primary applications of injection molding in this industry of electronica are:

Outer Casings/Housing

These are housings for items like laptops, smartphones, gamepads, and wearable tech that protect the interior parts while contributing to the product’s aesthetics.

Components and Attachments

Components and attachments, such asbuttons and switches, are produced through injection molding because they are essential pieces. Buttons include power buttons, function keys, or volume controls on devices like game controllers and remote controls. These components are made to provide the proper tactile feedback and to be strong enough to endure frequent use.

Connectors and Ports

These include HDMI, audio jacks, and USB, which require high-level accuracy to function properly and are highly dependable connections in most electrical devices.

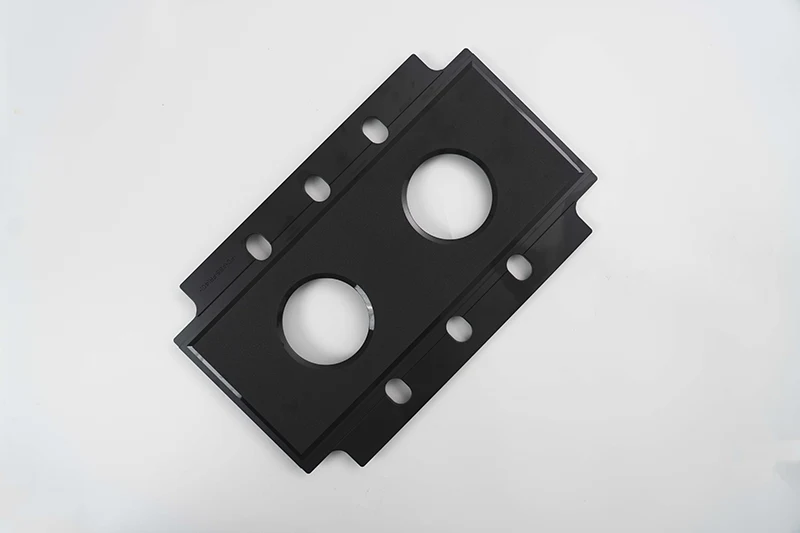

Internal Structural Parts

Theinjection molding processis also utilized to create structural components such as mounts, brackets, and holders that stabilize circuit boards, batteries, and other delicate electronics.

Heat Sinks and Shielding

Plastic heat sinks with embedded metal parts are important for dissipating heat generated from electrical components like power supplies and processors. Overheating results in long—term damage and reduces the components’ performance.

EMI shielding is integrated into custom plastic housings through the use of conductive coatings or metal shielding layers inserted into the mold during the molding process

To function reliably in diverse environments, electronic devices like computers, tablets, and smartphones require effective shielding.

Some designs incorporated in injection molding processes help to protect against electromagnetic interference (EMI), notwithstanding proper fitting into the device’s structure.

Insulating Cases

Insulating cases are essential in designing and manufacturing consumer electronics, safeguarding internal components, and providing electrical insulation to ensure safe operation. Some electronics like gaming consoles and wearable devices are typically made from non-conductive plastics like polycarbonate(PC) and acrylonitrile butadiene styrene (ABS).

The precision of injection molding ensures tight tolerances and makes insulators fit perfectly without taking up too much space. Insulating cases can offer structural support and hold internal components in place. Additionally, they can help protect components from vibrations and physical shocks.

Decorative Finishing and Branding

They are significant for product differentiation, aesthetic enhancement, and improved customer experience in injection molding. Decorative finishing: Add to the visual appeal and texture of the products. Techniques used include:

Hydrographic printing, commonly referred to as water transfer imaging, allows the application of intricate patterns like carbon fiber or wood grain onto plastic surfaces. It is famous for adding aesthetics to devices like headphones or gaming controllers.

Laser Etching removes small layers of material from plastic surfaces to create a permanent decorative effect. It is used for features like logos and serial numbers.

Tampografia: this is the technique used to affix labels, emblems, or logos to molded surfaces. Primarily applied on tiny components like buttons, computer accessories, remote controls, etc.

Branding: manufacturers incorporate branding directly into the product design during injection molding.

In-Mold Labeling (IML): This approach integrates the labels and graphics into the mold, eliminating the need for extra processing and permitting a quality, long-lasting brand.

Embossing and Debossing: these techniques let you imprint brands or graphic elements either raised (embossed) or recessed (debossed) directly onto the plastic. This improves the visual appeal of devices like speaker grilles.

In-mold decoration (IMD): allows integration of decorative elements directly into the mold itself, like designs and textures. Since the branding is embedded in the product’s surface, it resists wear.

Common Materials Used In Consumer Electronics Injection Molding

Several factors greatly influence the performance of the product. One of them is the type of material used. Material choice can significantly affect the product’s performance and durability. These materials must always meet specific criteria such as being lightweight, resistant to harsh conditions, capable of holding intricate designs, etc.

Acrilonitrile Butadiene Stirene (ABS)

ABS is a highly sought-after plastic because of its exceptional properties. Its material strength, durability, and ability to withstand heat are incomparable. ABS is easily moldable into intricate shapes and has good dimensional stability. It is applicable in the housing of smartphones, keyboards, and televisions.

Polyamide (Nylon)

Polyamide or nylon is a durable and flexible material with excellent abrasion resistance and high melting points. It is ideal for electronics frequently subjected to harsh environments because it exhibits robust chemical resistance. It is applicable for connectors, gears, and most internal components.

Acrylic (Polymethyl Methacrylate – PMMA)

Acrylic is a lightweight, clear plastic highly resistant to ultraviolet (UV) rays. Manufacturers can use it in place of glass and has excellent weatherability. Acrylic is used in electronic products, including displays, protective screens, and light guides for smartphones, tablets, and LED lighting fixtures.

Policarbonato (PC)

When it comes to transparency, strength, and great impact resistance, PC is unparalleled. It is suitable for electronics due to its good electrical insulation properties. Its ability to be molded into clear parts makes it ideal for products like LED light covers and smartphone screens.

Thermoplastic Polyurethane (TPU)

It is a flexible, rubber-like material that is highly scratch-resistant. TPU is commonly fit for flexible components, such as cable protectors and wearable devices, because it offers an ideal mix of flexibility and durability.

Polybutylene Terephthalate (PBT)

PBT is a common thermoplastic engineering polymer used in injection molding. It is renowned for its strength, resilience to heat, and durability. It is found in appliance components, handles, and high-wear devices.

Comparison Table Of The Materials

| Proprietà | Acrilonitrile Butadiene Stirene (ABS) | Polyamide (Nylon) | Acrylic (PMMA) | Polibutilene tereftalato (PBT) | Policarbonato (PC) | Thermoplastic Polyurethane (TPU) |

| La forza | Alto | Alto | Moderato | Alto | Molto alto | Moderate to High |

| Resistenza agli urti | Alto | Alto | Basso | Alto | Molto alto | Alto |

| Flessibilità | Basso | Alto | Basso | Moderato | Moderato | Molto alto |

| Resistenza al calore | Moderato | Alto | Basso | Alto | Alto | Moderate to High |

| Isolamento elettrico | Buono | Moderato | Buono | Eccellente | Buono | Eccellente |

| Resistenza chimica | Moderato | Alto | Basso | Alto | Alto | Alto |

| Trasparenza | Opaque | Opaque | Excellent (Clear) | Opaque | Transparent | Opaque |

| Ease of Processing | Easy to mold | Moderato | Moderato | Easy to mold | Moderato | Moderato |

| Stabilità dimensionale | Alto | Moderato | Moderato | Alto | Alto | Moderato |

| Resistenza all'abrasione | Moderato | Alto | Basso | Alto | Moderato | Molto alto |

| Costo | Moderato | Moderate to High | Basso | Moderato | Alto | Moderato |

| Applicazioni comuni | Housings, keyboards, remote controls | Gears, connectors, internal parts | Displays, light guides, covers | Electrical connectors, switches | Laptop covers, screens, lenses | Phone cases, wearable electronics |

| Resistenza ai raggi UV | Povero | Povero | Eccellente | Moderato | Moderato | Moderato |

| Assorbimento dell'umidità | Basso | Alto | Basso | Basso | Basso | Moderato |

| Resistenza ai graffi | Moderato | Moderato | Basso | Moderato | Alto | Moderato |

Technologies In Consumer Electronics Injection Molding

As the demand for the consumer electronics industry continues to grow and evolve, more efficient and feature-rich devices are needed. To satisfy this demand, manufacturers adopt advanced technologies to achieve the requirements.

Multi-Shot Molding

An advanced technique in which two or more different materials are injected into the mold in stages to produce a single part. You can combine multiple materials in a single process to reduce the number of assembly steps. As a result, the overall product costs are lowered. This process helps produce devices with various colors, materials, and textures.

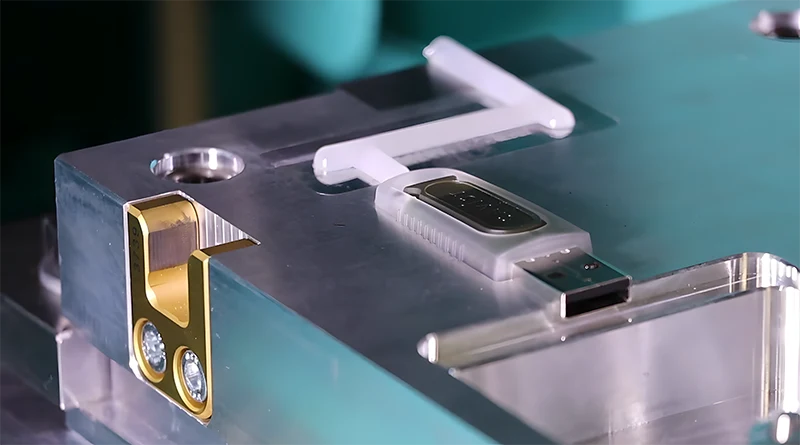

Insert Molding in Electronics

Insert Molding involves using pre-formed parts, usually metal inserts like terminals, into a mold and injecting plastic around them. This technique combines plastic and metal in one step, making it cost-effective. The process eliminates the need for secondary operations like soldering or fastening. It’s advantageous in electrical devices requiring mechanical strength and electrical contact.

Overmolding Technology

During the over-molding procedure, one material is molded over another. The combination forms a composite product with improved functionality and properties. Overmolding adds layers of protection to delicate components in consumer electronics.

Automation and Smart Manufacturing

Automation and smart production are driving the future of injection molding in consumer electronics. Injection molding has recently benefitted from implementing machine learning, robotics, and real-time monitoring techniques. These technologies assist in maximizing output, reducing human error, and optimizing accuracy. Automation can handle complex operations like part removal and placement, ensuring consistent production. Smart manufacturing, on the other hand, allows manufacturers to streamline processes.

Challenges In Injection Molding For Consumer Electronics and Ways to Mitigate Them

1. Complex Mold Design

Some parts, such as tiny connectors and internal components, call for complex geometries and tight tolerances. Accurate cavity measurements and high precision are necessary to design molds for these pieces. Advanced computer-aided design (CAD) software and mold flow analysis tools are essential to predict potential problems in mold design and create accurate designs.

2. Material Shrinkage

Material contraction after cooling and solidifying can cause it to shrink. This can result in dimensional inaccuracies and potential functional issues. Careful material selection with predictable shrinkage rates and adjusting mold dimensions to compensate for the contraction are crucial.

3. Warping

Warping occurs when molded parts twist or bend after cooling at varying rates, resulting in part distortion. It is particularly challenging for large or thin-walled components, affecting their fit and functionality. Balancing the mold designs and controlling the cooling rate across the entire part can manage this problem.

4. Thin-Walled Components

Thin-walled components are found in many electronic gadgets, making them more portable and energy-efficient through their reduced weight and size. However, these thin walls make it more challenging to achieve uniformity during the injection molding process. Inadequate pressure or flow speed can cause short shots (incomplete filling) or weak regions in the component, whereas flash (excess material) might result from overfilling. Manufacturers can use high-speed injection molding machines to ensure the materials fill these thin walls before cooling occurs.

Future Prospects in Consumer Electronics Injection Molding

With the evolving world, it is essential to know the trends in injection molding to counter competition. These trends are emerging to address sustainability and efficiency, revealing that the industry is competitive, innovative, and efficient.

Automation and Industry 4.0

Industry 4.0 is transforming injection molding. Smart manufacturing increasingly incorporates technologies like IoT, artificial intelligence, and machine learning. These technologies provide the advantages of real-time tracking, which can lower expenses, increase quality, and improve efficiency.

Micro-Molding

Growing demand for smaller and more precise components drives the development of micro-molding technologies. These parts are applied in compact appliances and wearable electronics. With this technology, manufacturers can create lighter and smaller components, supporting the overall trend toward miniaturization.

Additive Manufacturing Integration

3D printing is a popular method for rapid prototyping. Manufacturers frequently use it to produce custom parts that meet the specific requirements of injection molding. This has the advantage of combining approaches that can be very useful in different ways. It allows manufacturers to develop and test prototypes involving a few products, making the process relatively cheaper and faster. This method helps reduce lead times and costs associated with traditional prototyping. The use of this technology is now widely adopted across various fields, including manufacturing, healthcare, and the automotive industry.

Sustainability and Green Manufacturing

Manufacturers are increasingly emphasizing the use of eco-friendly materials and processes. This includes recycled materials, bio-based and biodegradable plastics, and energy-efficient injection molding machines.

Enhanced Prototyping and Simulation:

Advanced, powerful simulation tools are taking design optimization to the next level. Before the manufacturing process starts, these tools help create accurate models in computer simulations. This saves the need for physical prototypes for trials and ensures that the final design is the best possible option for manufacturing. Simulation speeds up the development process while reducing the overall cost of production.

Conclusione

Injection molding is crucial in the consumer electronics industry, as it allows the consistent production of different products. With a strong push for sustainability, manufacturers are embracing eco-friendly materials and processes. Various innovations enable the creation of better components, meeting today’s tech demands. As we move forward, the industry’s commitment to greener practices will not only benefit the planet but also drive development.