The use of injection molding continues to rise in the production of aerospace products. The method is ideal for producing large quantities of small but intricately designed and lightweight parts.

In the past, aerospace parts involved the usage of metals through techniques such as machining and casting. These methods may be expensive, time-consuming, and labor-intensive.

Using composite and high-performance plastics has rendered injection molding suitable for aerospace applications seeking to enhance production while maintaining the necessary accuracy. Injection molding enables the manufacturing of intricate shapes and narrow tolerance levels, which are helpful in aerospace production to conform to high performance and safety requirements.

Components with sufficient strength, heat resistance, and low density are desirable in aerospace. These properties ensure fuel efficiency and improved overall aircraft performance.

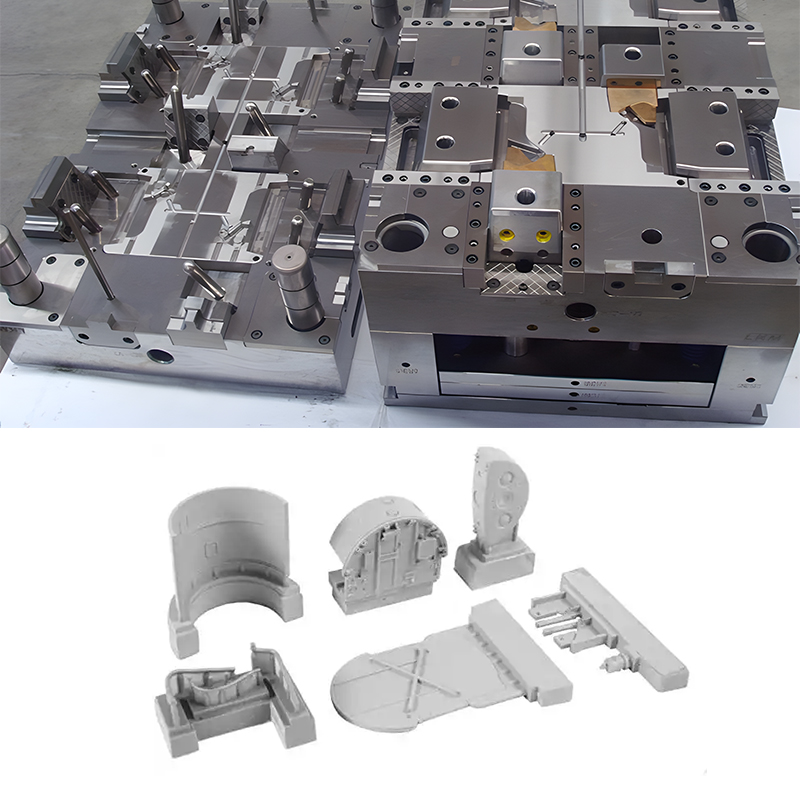

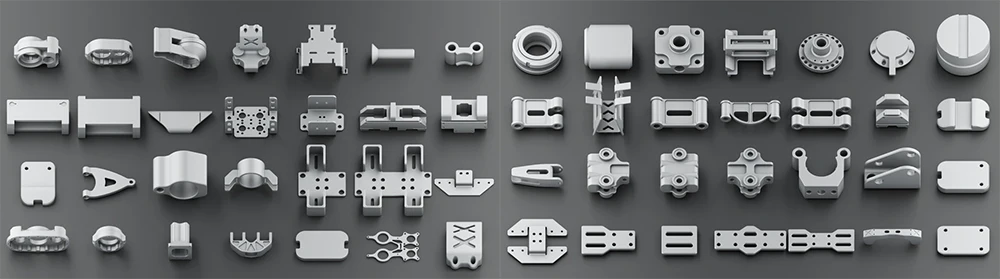

Common Aerospace Injection Molding Parts

Injection molding is ordinary in manufacturing aerospace products, primarily due to its suitability in generating lightweight, accurate, and robust products. Below is a description of critical standard aerospace components from injection molding:

Interior Components

Injection molding makes various components of the overhead control panel’s car seats, armrests, and lid. These parts have to be both light in weight and strong. Thermoplastics and composites fit these requirements perfectly.

The process involves manufacturing complex geometries, thin walls, and delivery systems. Dial faces and other parts of control knobs, instrument surrounds, and other components of the cockpit are often products of injection molding.

These parts have great accuracy, functional and ergonomic efficiency, fire and heat proofing, and reasonable durability.

Brackets and Mounts

Injection molding supports varied aircraft systems, such as electrical wiring and hydraulic systems. These brackets are usually made of strong, lightweight plastic or composite material. They operate in vibration and stress conditions with low aircraft weight. Sometimes, specialist injection moldings can produce engine mounts and housings. These components must work under high mechanical loads and temperatures and, therefore, be made of highly stable materials.

Cable Clamps and Fasteners

Mechanical products like cable clamps and fasteners for managing wires, tubes, and cables are injection molding products. This process is suitable for small and accurate Parts.

The load acts on these components, which means that the components need to be light and robust. This prevents the loads from moving or induces damage during the flight.

Most small and large fasteners, clips, and connectors are injection molding products. This process enhances accuracy, and the resulting products reduce the airplane’s overall weight. These parts are valuable for non-structural applications where strength and durability remain paramount.

Electronic Component Housings

Injection molding produces housings for electronics like sensors, control systems, and navigation equipment. These housings shield the compact and often delicate electronics from the effects of temperature, moisture, and mechanical pressures.

Battery compartments from lightweight injection molding materials provide insulation and exterior protection to electrical arrangements in the aircraft. These housings are anti-electrical interference and light enough that they will influence general fuel efficiency totals.

Composite Structural Components

Many subassemblies, including fuselage panels and wing parts, are standard injection molding products with composite materials. They are strong but lighter, lowering the fuel cost and raising the aircraft’s efficiency. Other components are rib reinforcement, spars, and other parts that are highly important to constructing an aircraft’s frame.

Ducts and Vents

Injection molding is required to produce intricate contours, ducting, vents, and air conditioning passages within the aircraft. These components require accurate fabrication to adjust the proper airflow and temperatures in the cabins and other parts of an airplane.

Grommets and Seals

The injection-molded grommets and seals are essential to seal all points where dust, moisture, or air should not penetrate the aircraft. These components are made from specific grades of plastics or rubber-like materials compatible with servicing high-temperature or pressure abnormalities. Some of the seals and grommets also act as vibration-absorbing parts, helping various systems in aircraft last longer and significantly contributing to quietness.

Switches and Buttons

Injection molding generates lightweight devices for operational switches and control buttons, knobs, and panels within the cockpit and passengers’ sections. These parts require sustainability, flexibility, and resistance to wear, and sometimes they are created with complex forms to improve their performance.

Lighting Components

Generally, complex components such as housings for aircraft interior and exterior lighting, cabin lighting equipment, navigation lights, and landing lights are injection-molded. Such parts must also be made of construction materials that can withstand heat and other environmental conditions while remaining optically clear and very durable.

Bumpers and Pads

Protective bumpers and pads installed on cargo areas and baggage compartments of the plane in question are usually produced by injection molding. These parts are also used for damping and noise control and to protect the interior or exterior of the aircraft during loading and unloading.

Insulation Panels

Another application of injection molding is the production of lightweight insulation panels to regulate temperature and noise in aircraft. Such panels may contain high-tech polymers with heat, sound, and fire resistance characteristics.

Componenti del sistema di alimentazione

Fuel systems incorporate injection-molded products such as fuel caps, seals, and fittings. These parts must be immune to fuel and designed to endure high pressure while providing a safe, seal-tight environment.

Landing Gear Covers

Injection molding is employed in manufacturing covers for landing gear assemblies to minimize drag and preserve the gear from external conditions. These lightweight components must possess enhanced mechanical strength to support forces and impact loads.

Considerazioni sulla progettazione

Manufacturers must consider numerous factors when designing parts for the injection molding process with applications in aerospace. The fundamental techniques include lightweight engineering and different technologies such as lattice geometric structure and topologic engineering. Lightweight engineering is critical to the improvement of fuel economy and acceleration. The following table summarizes design considerations for aerospace injection molding.

Table of Different Design Considerations

| Design Consideration | Descrizione | Key Techniques | Impact | Challenges | Examples of Application |

| Weight Optimization | Minimizing weight to enhance fuel efficiency and performance in aerospace applications. | – Lattice Structures – Topology Optimization | – Increases fuel efficiency – Improves payload capacity – Enhances overall performance | – Balancing strength and weight – Material selection | – Aircraft brackets – Structural components |

| Geometrie complesse | The ability to create intricate designs that are challenging to achieve with other manufacturing methods. | – Ribs – Bosses – Undercuts | – Improves part functionality – Enables innovative designs that meet specific requirements | – Tooling complexity – Longer design cycles | – Interior components – Ducting parts |

| Surface Finish and Tolerance | Requirement for tight tolerances and specific surface finishes to meet aerospace standards. | – Precision Injection Molding – Consideration of Shrinkage and Warping | – Ensures component reliability – Meets regulatory standards for safety and performance | – Variability in material properties – Post-processing requirements | – Engine components – Load-bearing structures |

| Selezione del materiale | Choosing appropriate materials for aerospace parts’ strength, weight, and thermal requirements. | – Advanced Polymers – Metal-Polymer Composites | – Optimizes strength-to-weight ratio – Enhances durability and performance | – Availability of materials – Cost implications | – Electrical enclosures – Housing parts |

| Manufacturing Consistency | Ensuring uniformity in part production to meet strict aerospace specifications. | – Process Control – Quality Assurance Measures | – Reduces defects – Increases reliability of components | – Variability in production processes – Quality control challenges | – Safety-critical components – Aerospace interiors |

| Regulatory Compliance | I adhere to industry standards and regulations for safety and performance in aerospace applications. | – Certification Processes – Compliance Testing | – Ensures parts meet safety standards – Facilitates market entry | – Complexity of regulations – Time-consuming certification | – Components subject to FAA regulations – Parts for military aircraft |

| Progettazione per la producibilità (DFM) | Incorporating manufacturing capabilities into the design phase to enhance production efficiency. | – Simplified Designs – Modular Approaches | – Reduces production costs – Streamlines manufacturing processes | – Balancing design complexity with manufacturability | – Assembly components – Modular subassemblies |

| Thermal and Environmental Resistance | Designing parts to withstand extreme temperatures and environmental conditions typical in aerospace. | – High-Performance Materials – Coatings | – Enhances reliability in harsh conditions – Increases the lifespan of components | – Limited material options – Testing for environmental compliance | – Engine components – External structures |

Materials Used in Aerospace Injection Molding

Material selection is vital in aerospace injection molding because of airline parts’ severe working conditions and stringent performance demands. High-temperature thermoplastics like PEEK, polyimides, or PPS are popular. These plastics have superior strength, high durability, and resistance to heat & chemicals.

For instance, PEEK has a glass transition temperature of around 260°C, with excellent mechanical characteristics. It is common in stress-bearing areas such as seals and brackets.

Polyimides are popular because of their high heat and electrical resistivity in electrical and engine applications. In particular, PPS has excellent chemical resistance and is characterized by stability in dimension under thermal conditions. Therefore, this material can be helpful in fuel system parts and electrical contacts. These thermoplastics can enable the fabrication of structural, as well as non-structural, components in aerospace applications. They provide necessary performance without the extra volume.

Glass-Fiber Reinforced Polymers (GFRP) and Carbon-Fiber Reinforced Polymers (CFRP) composites are also essential for aerospace injection molding. They have a tremendously high strength-to-weight ratio of the composite material. GFRP is expected in the continuous parts, including covers and casings, where the service life, combined with low weight, is desirable. CFRP produces parts like wings and fuselage, in which high strength with minimum weight is essential.

Other materials such as polyamide (nylon) and Teflon offer versatility to aerospace components due to their wear, friction, and chemical-resistant properties. Polycarbonate materials offer high-impact strength and light transmittance. They find application in aircraft cabins, windows, and light shields.

Different Materials

| Materiale | Resistenza alla trazione (MPa) | Flexural Modulus (GPa) | Max Operating Temp (°C) | Densità (g/cm³) | Key Features | Common Aerospace Applications |

| PEEK (Polyether Ether Ketone) | 90-110 | 3.6-4.0 | 260 | 1.30-1.32 | High strength, chemical, and thermal resistance, excellent wear properties | Engine components, seals, brackets |

| Polyimide | 100-160 | 4.0-5.5 | 315 | 1.43-1.47 | Outstanding thermal stability, excellent electrical insulation | Bushings, high-temp electrical components |

| PPS (Polyphenylene Sulfide) | 90-110 | 3.0-4.0 | 200 | 1.35-1.40 | Chemical resistance, dimensional stability under heat | Fuel system parts, valve housings, electrical connectors |

| GFRP (Glass-Fiber Reinforced Polymer) | 120-150 | 7.0-10.0 | 180 | 1.50-2.00 | High strength-to-weight ratio, good corrosion resistance | Structural components, enclosures |

| CFRP (Carbon-Fiber Reinforced Polymer) | 500-1000 | 50-100 | 250 | 1.55-1.60 | Superior stiffness, excellent fatigue resistance | Fuselage panels, wing spars, load-bearing structures |

| Nylon (Polyamide) | 75-85 | 2.6-3.3 | 120 | 1.12-1.15 | High wear resistance, good fatigue strength | Interior trim, brackets, bushings |

| PTFE (Polytetrafluoroethylene) | 20-30 | 0.5-0.7 | 260 | 2.20-2.30 | Low friction, chemical inertness, excellent high-temp performance | Seals, gaskets, bearings |

| Policarbonato (PC) | 60-70 | 2.1-2.4 | 135 | 1.20-1.22 | High impact resistance, flame retardance, optical clarity | Windows, light covers, cockpit interior components |

Future Trends in Aerospace Injection Molding

Aerospace injection molding is set to experience further advancement in the future. New technologies and materials in the aerospace injection molding industry will likely emerge to meet the rising demands. The latest trend combines Additive Manufacturing (AM), or 3D printing, with injection molding. These processes can integrate to build a more complex geometry, optimize part shape in terms of minimum weight, and minimize remaining material. This technology allows the introduction of structures such as lattices that are otherwise nearly impossible via conventional molding methods. It improves the strength-to-weight ratio in aerospace applications.

Advanced composites, including CNT-embedded biopolymers and bio-based polymers, will enhance the mechanical characteristics of aerospace components and parts. They will minimize the effects of environmental and social responsibilities.

Using sensors and automated systems based on artificial intelligence will improve the accuracy and productivity of injection molding. These enable real-time monitoring of mold conditions and the ability to set such conditions as temperature and pressure for Parts production.

Aerospace manufacturers strive to attain ever higher efficiency and drive towards sustainability. Implementing these new trends will remain instrumental in augmenting the trajectory of aerospace injection molding.

Conclusione

Injection molding has become critical in creating aerospace parts because of the products’ high accuracy, low weight, and complex forms. The method delivers parts that are compliant with performance and safety concerns within the industry. Due to innovations in materials such as high-performance thermoplastic and composite reinforcements, the injection molding of aircraft parts has improved fuel efficiency and other aircraft performance. With new technologies such as additive manufacturing and artificial intelligence integration systems in contemporary society, the future aerospace injection molding is cleared for more efficient design and production of parts for more sustainable solutions in aviation.

Recommendation

To gain more insight into some of the challenges and critical points facing the production of aerospace parts, visit our “aerospace parts manufacturing sevice”. This page provides an overview of many aerospace components made through injection molding.