Plastic Injection Mold Making Service

The Injection mold is the core of the industry production

- Choose between DIY or our complete injection molding services.

- Rapid toolings for prototypes and production toolings for business growth

- Provide regular updates on mold production progress.

Overview of our injection mold making service

Our core competency in mold manufacturing lies in the following three stages:

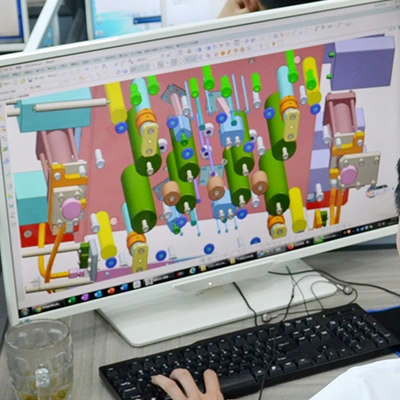

模具设计

Our injection molds are meticulously designed by mold designers with over a decade of experience, not only considering the quality and precision of the final injection-molded products but also the production speed, to maximize efficiency

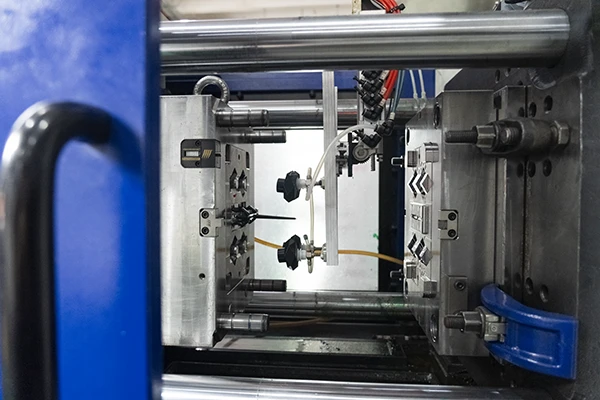

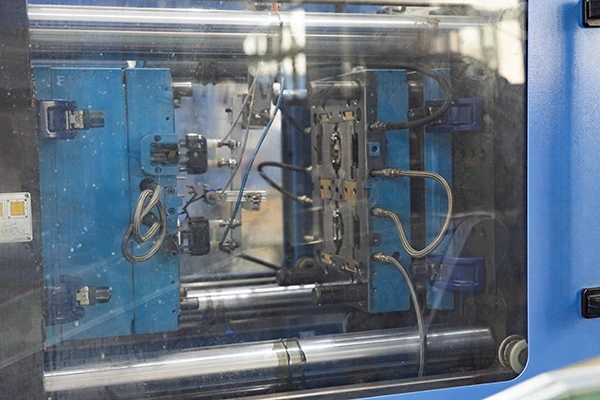

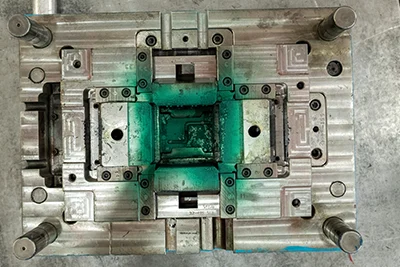

Mold Machining

The precision of mold processing depends on the accuracy of the machining equipment and the familiarity of the equipment programmers and operators with the machine, both of which are strengths of First Mold.

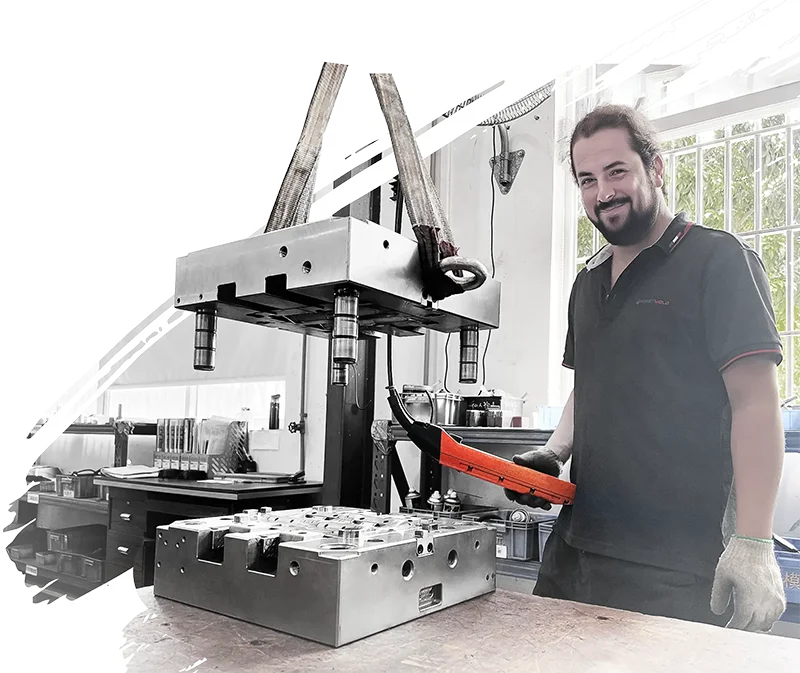

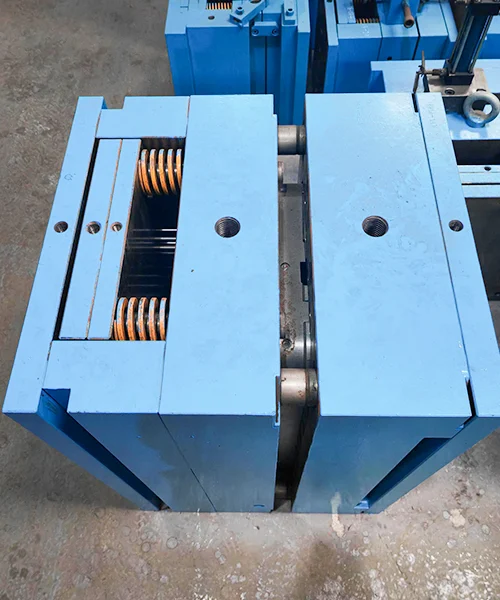

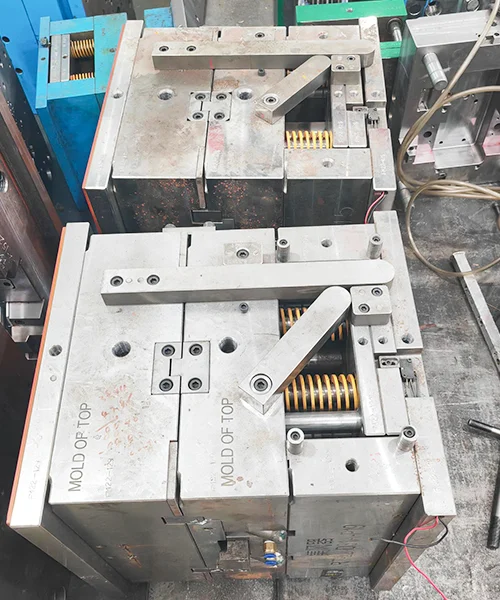

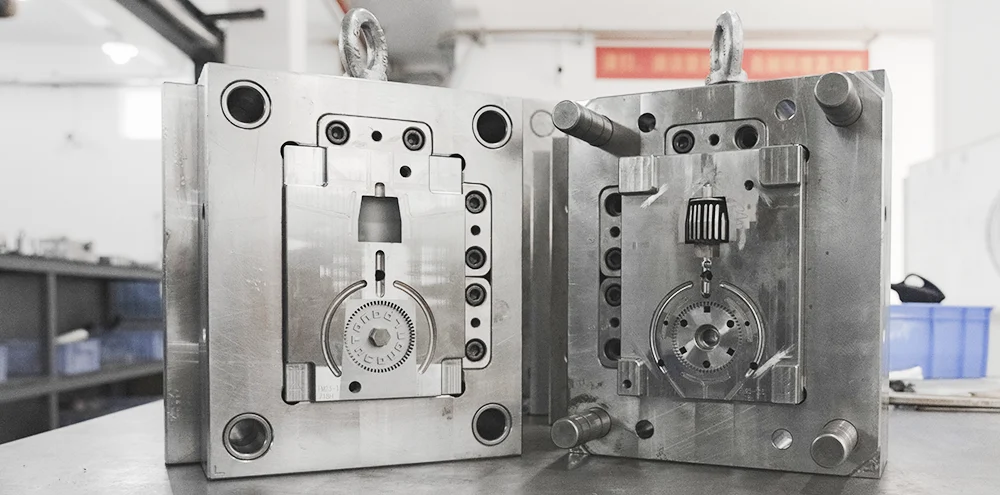

Mold Assembly

Mold assembly includes steps such as mold fitting confirmation and mold polishing, all of which are completed in First Mold's mold assembly workshop. To ensure the final injection-molded products are more precise, this step is repeated multiple times.

Strategic Mexico Facility: Accelerating Mold Making for North America

Except the China base, our Mexico facility in Silao is redefining the standards of plastic injection mold making for the North American market. Positioned strategically to minimize lead times and logistics costs, the facility specializes in rapid tooling, a game-changing solution for businesses seeking speed, precision, and cost-efficiency.

What Can We Do?

DFM

模流分析

模具设计

Rapid Tooling Production

High-Volume Mold Manufacturing

Insert Molding Tools

Multi-Cavity Mold Solutions

Hot Runner Mold Systems

Aluminum Tooling

Texturing

表面处理

Mold Trial

Mold Maintenance

Mold Repair

Mold Refurbishment

Gate Design

Parting Line Optimization

Mold Assembly

Shorter delivery times

Proximity to key manufacturing hubs across the U.S. and Canada.

Lower costs

Reduced transportation expenses and optimized production efficiency.

Rapid innovation

Accelerate your time-to-market with high-quality molds ready in record time.

Scalable Capacity

Both single prototype or high-volume production molds are acceptable.

- Recommended

Injection Molds Application & Injection Molded Parts

The ultimate goal of the injection mold making service is the production of injection-molded parts. The molds produced can either be used by the clients for their own injection molding production or entrusted to First Mold for injection molding production.

These cases demonstrate the use of injection molds in the injection molding process and the final formed products.

Watch a Video of Our Plastic Mold Making Services

Types of injection molds we serve

The injection molds we manufacture can be classified into several categories based on different criteria:

“Working with First Mold transformed our approach to product development. Their expertise in injection mold making is unparalleled. From rapid prototyping to full-scale production tooling, they’ve consistently delivered molds of exceptional quality. Their attention to detail and commitment to precision have significantly reduced our time to market, enhancing our competitive edge.”

Alex Johnson

Senior Product Engineer

First Mold’s injection mold making service has been a game-changer for our automotive component production. The precision and durability of their molds have ensured flawless part production, meeting our strict quality standards. Their ability to work with complex designs and materials has allowed us to innovate freely, knowing that First Mold can bring our visions to reality.

Sarah Thompson

Project Manager

By Usage Frequency:

- 快速工具

Designed for quick, short-run productions, allowing for fast prototyping and testing.

- 生产工具

Built for long-term, high-volume manufacturing, ensuring durability and stability throughout the production process.

By Material:

- Aluminum Molds

Preferred for their quicker machining time and lower cost, suitable for lower volume productions.

- Steel Molds

Chosen for high-volume production due to their superior durability and longevity.

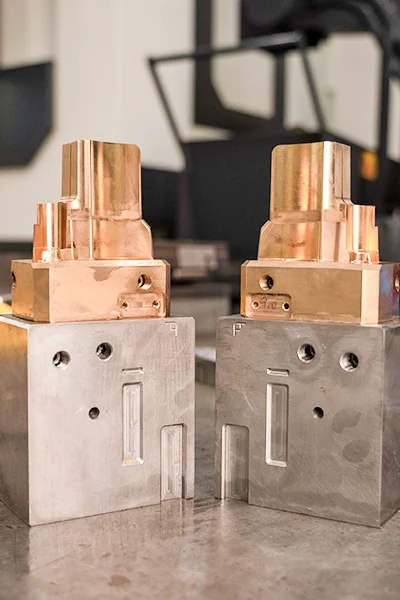

- Beryllium Copper Molds

Utilized in specific parts of the mold that require unique properties, such as thermal conductivity, in beryllium copper alloyed molds.

By Demolding Mechanism:

- Two-Plate Molds

The simplest and most common type, where the mold splits into two halves to eject the part.

- Three-Plate Molds

More complex, allowing for automatic demolding and the creation of more intricate parts, with an additional plate for runner and gate system separation.

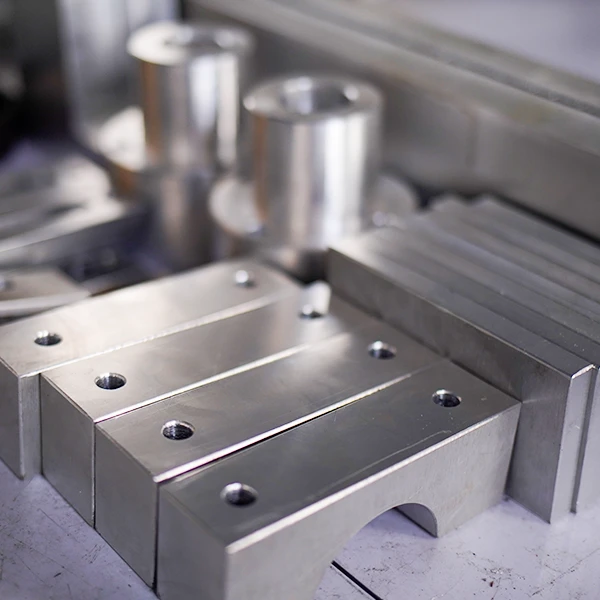

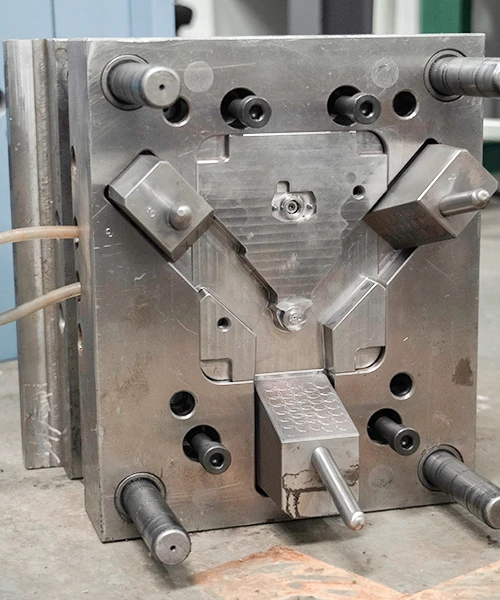

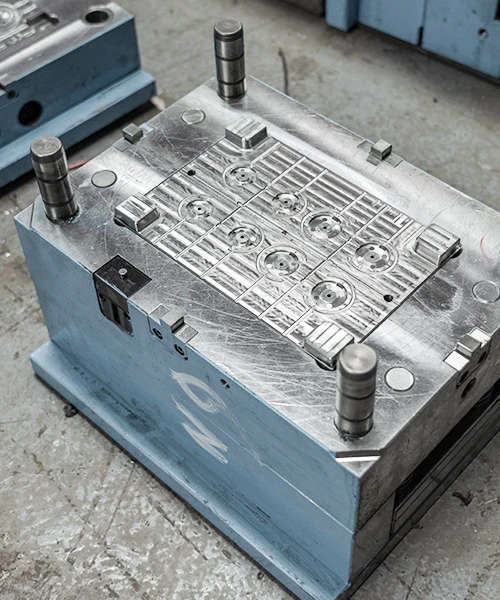

Injection mold components we process

Our injection molds are typically fabricated using CNC machining or EDM (Electrical Discharge Machining) processes. The components made for these molds include:

- Injection Mold Base

- Injection Mold Core

- Injection Mold Cavity

- Injection Mold Insert

- Injection Mold Slider

- Injection Mold Lifter

- Injection Mold Guide Pin

- Injection Mold Guide Bushing

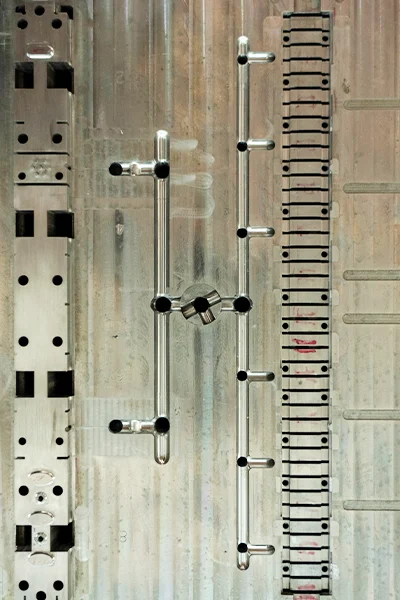

- Injection Mold Ejector Pin

- Injection Mold Runner

- Injection Mold Cooling System

Unlock Production Potential with a Click

Why We Stand Out

Three reasons underpin the success of our mold manufacturing service to date:

Over a Decade of Mold Design Experience

Our approach to mold design is grounded in reality, not whimsical ideas. Our designers are our most valuable asset, boasting over ten years of experience in aesthetic and structural design aspects such as wall thickness, material selection, snap-fit design, and boss design. They know how to efficiently and swiftly complete the design of injection molds.

Advanced Machining Equipment and Professional Operation

We have invested in a wide array of high-precision machines from renowned brands like Haas, GF+, and Makino, specifically tailored to handle complex machining tasks involving deep structures, curved surfaces, and smooth finishes. This ensures the high quality of our injection-molded products.

Competitive and Stable Pricing System

Thanks to our efficient production management system and stable supply chain for metal materials, we offer highly competitive prices in the global market without compromising on quality. Rest assured, we can provide material certifications to back up our quality claims.

Submit Product Drawings

Step One

Simply provide us with your product drawings. We will hold a dedicated meeting to assess your project and issue an initial report.

Product DFM Analysis

Step Two

We will produce a DFM (Design for Manufacturability) report or mold flow analysis report and communicate with you to confirm your requirements.

模具设计

Step Three

Upon your confirmation, our mold designers will use all the collected requirement information for professional mold design.

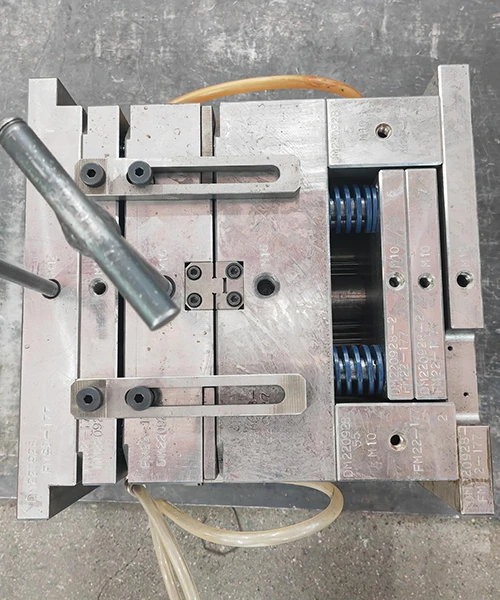

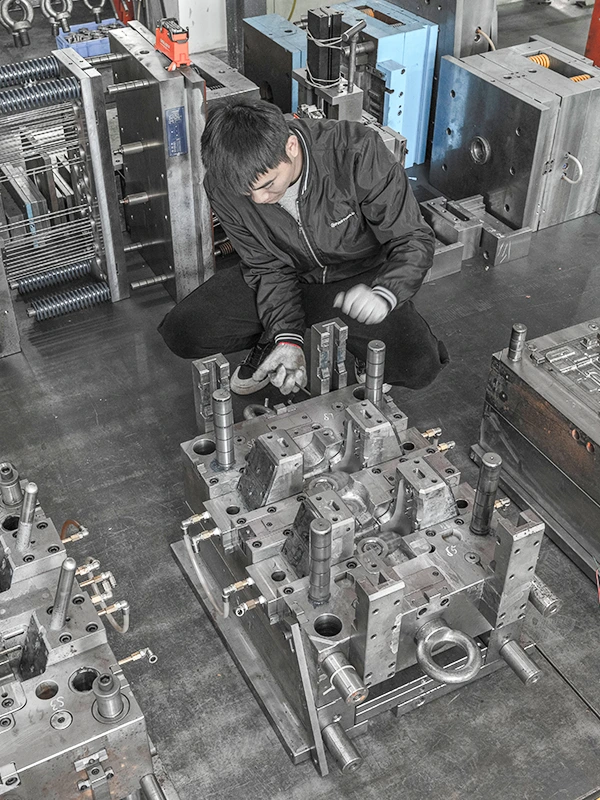

Mold Manufacturing

Step Four

Our CNC workshop will begin manufacturing the mold components, which will then be inspected by our quality control department.

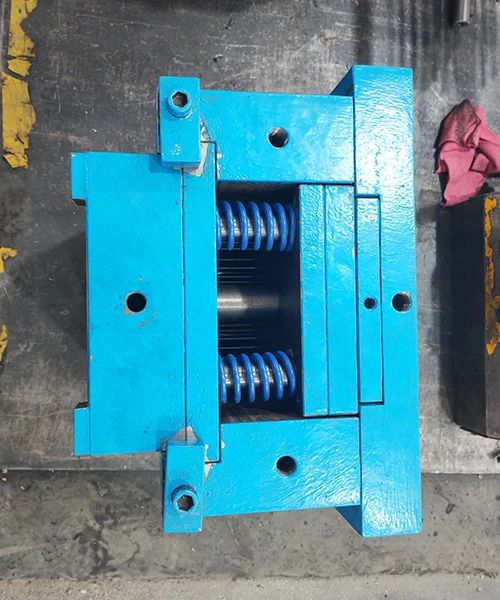

Mold Assembly

Step Five

We will perform multiple mold fittings and polishings to ensure mold precision and prevent various injection molding defects during use.

Delivery For Use

Step Six

Your custom-designed injection mold is meticulously inspected, packaged, and delivered, ready for immediate use in production.

Surface Finishing and Post-Processing in Injection Mold Making Services

Due to varying customer needs, the majority of molds produced by First Mold undergo surface treatments and post-processing. By default, we apply a high-gloss finish to make the final injection-molded product surface smoother. In addition, we utilize techniques such as sand blasting and etching to treat the surfaces of mold parts.

To enhance mold hardness or lifespan, we typically subject the completed injection molds to post-processing treatments like heat treatment and nitriding.

Delivery Times and Trial Runs for Different Injection Molds

Our mold delivery timeline begins from the moment you confirm the order and we start the mold design, and it extends up to the first trial run phase.

For rapid tooling, we typically complete the process within 7 days, whereas for production molds, the timeline usually spans 30-45 days. Given that production molds require more time to complete, our team will maintain close communication with you to ensure your requirements are met.

Prior to the first official trial run, we conduct internal trial runs. Additionally, we will undertake 2-3 more trial runs to effectively identify and eliminate potential injection molding defects that could arise during production.

Seize Efficiency with a Click

Overview of the Mold Workshop and Mold Department

If you are not very familiar with injection molds, you can click the link to learn about "What is an Injection Mold"