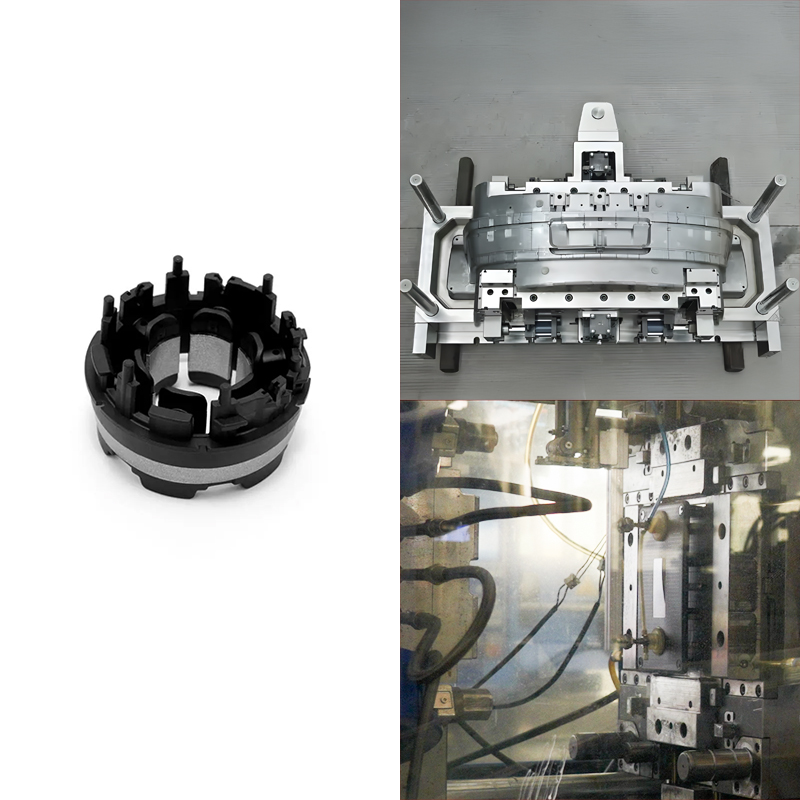

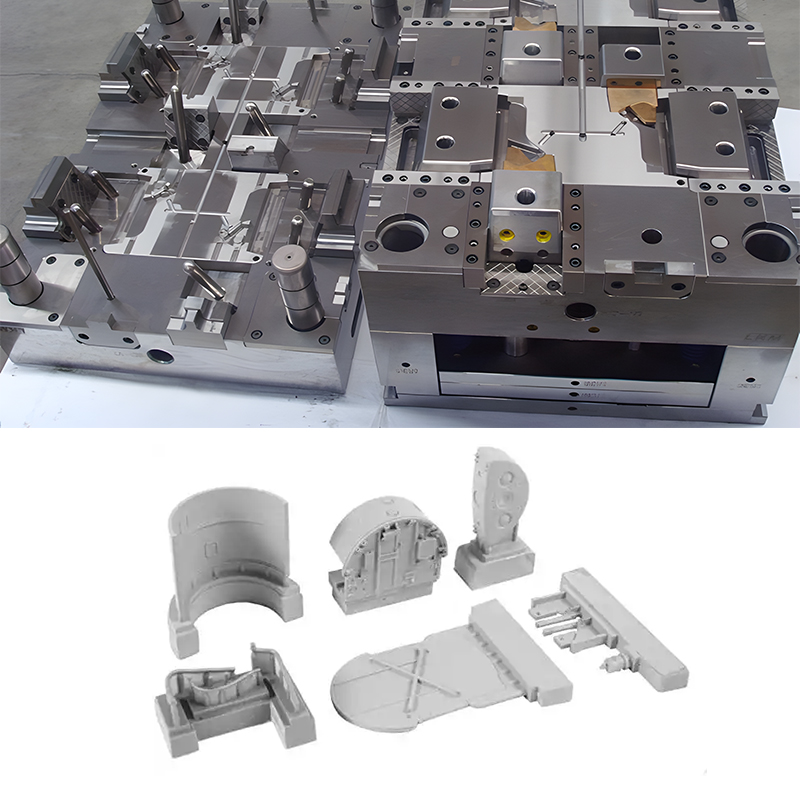

Injection molds are unique manufacturing tools for creating plastic parts. It involves inserting molten plastic into a pre-determined space. In this process, technicians heat local solid polymers called pellets containing plastic until the heat turns them into liquid. They then pump the molten polymer at very high pressure into a mold, rapidly cooling and hardening into the required shape. A mold Includes the cavity and the core as its primary two sections. The molds facilitate the uniform generation of intricate forms with tight tolerances. When the plastic cools, operators open the mold and eject the finished part. Operators can effectively repeat the process quickly, making injection molding a central part of modern production.

The applications of injection molds include the automobile, aerospace, consumer products, health, and electronics industries. They offer a cheaper method of creating large volumes of similar items. Injection molding is cost-effective and produces numerous parts. It accommodates virtually all thermoplastic and thermosetting materials, padding the producer’s hand regarding material selection for an application.

Common Issues That Might Lead To Injection Mold Repair

Injection molds have a few problems that can affect the flow of production and the quality of the end product. Wear is one of the top risks that creates significant problems and carries high costs. Long-term usage in high-stress situations may degrade mold elements, such as the cavity, core, and ejector pins. Consequently, there needs to be more resolution. Common defects include parts with poor finishes or parts with only partial fill. The use of abrasive materials and inadequate maintenance hasten this kind of wear. Therefore, repairs or even mold overhauls are necessary to produce high-quality products.

Another common problem is porosity, which is the formation of non-desirable patterns, spots, marks, or unevenness directly on the surface of the finished operative part. Some possible causes include wrong temperature settings, improper material flow, and contaminated mold surfaces.

Further, improper alignment between the two halves of the mold, such as the core and cavity, results in difficulties. The critical issue is the flash, which is extra material at the mold’s parting line. Solving these problems sometimes needs constant care, fine-tuning, and the proper mold-hand shift for effective performance and high-quality part output.

Signs That You Need an Injection Mold Needs Repair

Operators can detect failure patterns in an injection mold early enough to avoid injection mold repair or replacement costs and losses due to a lack of production. Numerous signs indicate that the injection mold requires repair.

Flash Formation

One crucial first indication that your injection mold needs work is visible flashes on the final part. Flash means that material, after injection, goes out through the parting line. A flash occurs because of the mold misalignment or wear of the mold part. As molds age, the specificity of their tolerances is higher. Even the slightest deviation can create vents and leak the material. If operators ignore this issue, flash becomes evident in the appearance and usability of parts. It indicates that the mold requires realignment or the clamping system of the press requires repair.

Surface Imperfections

Any visible marks, dents, or uneven surfaces on the final parts show that the mold is probably worn out or damaged somehow. Such imperfections include problems like wear in the mold cavity, contamination, and inadequate venting. They lead to disturbance of material flow and cooling. Not only does it affect the product’s aesthetics, but it also negatively influences its stability. Such imperfections demand mold cleaning, polishing, or re-machining of the cavity surface.

Ejector Pin Issues

If certain parts provide a gradually greater level of difficulty in ejection or appear to have apparent marks of the ejection pin, it will be a sign of worn out. Sometimes, it implies that ejector pins require repair or replacement. In an ejector system, failure to work means that parts remain stuck to the mold. This situation results in the production of distorted products or longer cycle times. By performing muzzle inspection and replacing worn pins, operators solve ejector problems early. The early attention ensures proper part ejection without straining the mold.

Dimensional Inaccuracies

Another sign of mold repair work is the variation in the finished products’ thickness, size, length, breadth, and height. When molds start producing parts out of tolerance, either too big, too small, or uneven, it simply means wear and tear on the mold elements. These defects are common in the cavity, the core, or the guiding system. Attention to part dimensions is essential. Workers should make inspections and perform possible repairs if they notice something out of the ordinary.

Increased Cycle Time

A sudden spurt or change in the cycle time signals mold problems. Possible issues can include inefficiency in the cooling system, difficulties in material flow, or mechanical part wear. Long cycle times have negative implications that can affect operational costs and productivity levels. The actual cause of the delay may include low ASR and PSR, blockage in the cooling channels, worn-down parts, and misalignment.

Essential Tools for Injection Mold Repair

When repairing injection molds, operators use several specific instruments. The tools keep the mold in as precise a state as possible and thus regain functionality. Here are some essential tools for injection mold repair:

Precision Grinding Machine

A precision grinding machine is helpful in the manufacturing process to correct impurities on the surface of a mold. This tool shaves small quantities of material so the mold cavity and core have outstanding surface finish quality.

Welding Equipment

These machines can weld small, precise portions of the mold surface without affecting the surrounding surfaces, which is why they are helpful for mold repair.

Polishing Tools

This include diamond paste, polishing stones, and rotary tools. They give a high-quality surface free from surface marks, scratches, and roughness.

Measuring Instrument

Measurement instruments such as calipers, micrometers, and dial indicators are essential for inspecting and verifying dimensions. These tools help maintain the correct sizes and tolerances after repair.

Surface Plate and Height Gauge

A surface plate with a height gauge helps assess the flatness and parallelism of mold parts. This arrangement lets technicians ensure the mold has suitable parting surfaces to prevent flaws such as the flash.

Ejector Pin Removal Tool

Ejector pin pullers and installation tools are also applied to maintain the mold’s ejector system. These tools allow for the removal and replacement of worn-out ejector pins.

Personal Effects (Files, Spanner, and Screwdrivers)

Myriad hand tools fix the mold and make minor adjustments when conducting essential maintenance. Hammers are helpful while working around parts with burrs or sharp edges. Files can help reduce such edges. Spanners and screwdrivers can be beneficial in reassembling mold parts.

Cooling System Preventive and Diagnostic Equipment

These tools help clear blockages and return flow in the cooling channels and pipes. Their use is essential in the production process, where they regulate the time taken in each cycle to avoid overheating.

Lapping Machines

A lapping machine is mainly helpful for minor but very precise adjustments of mold contours. It leads to a perfectly flat surface of the mold’s components. However, it can be critical for holding highly accurate dimensions in molds where surfaces slide against each other and for different types of parting lines.

Inspection Microscope

Technicians may not be able to observe the mold because of minor mold defects or surface roughness on the mold face. They require an inspection microscope to examine the mold surfaces.

Step-by-Step Repair Techniques

Several processes are used to restore functionality and increase the operational life of an injection mold. These methods include welding and patching, surface grinding, component replacement, and reconditioning of cores and cavities.

1. Welding and Patching

Welding and overlaying repair cracks, chips, or any worn surface in the model. This process involves the following steps:

- First, ensure the surface is free of debris, contaminants, and any preliminary surface oxidation. Removing the entire layer helps obtain a clean surface where the weld can stick properly.

- Using micro-TIG or laser welding equipment, place the correct weld to cover the area involving damage. These techniques allow you to apply heat focus while limiting the deformation of the rest of the mold.

- Do not apply any pressure on the welded area. Instead, let it cool using cooling factors. In some cases, controlled cooling methods can minimize stress effects on the mold.

- After the weld has cooled, rough up the area with a grinder or a Polisher to meet the mold standard. This step further leads to a smooth part.

2. Surface Grinding

Surface grinding prolongs the use of its material by shaving a little material off-level rough areas and correcting slight surface imperfections. Here’s how the process works:

- Determine areas requiring grinding, such as zones of the mold cavity or a parting line with an excessively worn surface that is not flat.

- A precision grinding machine with the right abrasive wheel is used for the mold material.

- While grinding the area, ensure you have removed the suitable material. Use gentle pressure to flatten the cutting tool. Avoid over-grinding, which can change the size of the mold.

- After grinding, polish the area with polishing tools for a high-quality, smooth surface finish.

3. Replacement of Components

In some cases, some of the mold elements undergo permanent damage without repair possibilities. In such cases, the only solution is to replace them. It involves replacing parts and components, including ejection pins, springs, guide pins, or other parts. Follow these steps:

- Concentrate on the area where one of the components is faulty and requires disassembly. Prop up the mold, and be sure to label it. Labeling helps you easily keep track of these parts while reassembling the equipment.

- Remove the damaged or worn component carefully with proper hand tools (e.g., ejector pin pullers, wrenches, etc.).

- Check whether the new component you have added is fixed correctly. Any future misalignment may result in more damage. Use tools such as calipers to measure whether they fit well and perform as intended in a specialized application.

- Reassemble the mold you just took apart. Make sure that the pieces fit well back together again. It is also essential to do a trial run to ensure the proper adjustment of the alignment and functions of the mold. Take the mold back to production.

4. Reconditioning of Cores and Cavities

Reconditioning is applicable in wear or scratch degradation instances of core and. This process restores the critical mold surfaces to their original condition:

- Check the cores and cavities for wear, cracks, or deformation. The mold quality required to produce some molded products requires extra attention. Microscopes or magnifying tools scrutinize the molded parts for any minor defects.

- Grinding and polishing tools smooth the core and cavity surface and remove minor surface damage. In case of more profound defects, welding is induced. This deposits material and, finally, allows grinding and polishing.

- Check to see if the cores and cavities envisaged match the specific measurements. Degradation may also have occurred in other areas, requiring re-machining to restore the part’s dimension.

- Observe the operational temperature for a refined finish. Proper operational temperature aids in easy subtraction and improves the quality of the finished products.

Evaluating Repair vs. Replacement

Evaluating the possibility of repairing or replacing an injection mold involves different factors. Deciding between mold repair and replacement depends on the severity of the damage and the overall cost-effectiveness of each option. Repairing minor flaws like scratches, thinning of ejector pins, or minor cracks is often possible. In this case, repairing is more reasonable to keep up production.

In cases with significant damages like cracks, severe misalignment, and pronounced wear of the core or cavity, the use of repairs may be deceptive. The costs of continuous maintenance overwhelm the intended gains. In such cases, replacement may be more effective. Molds of several years, especially those exposed to constant repair, tend to wear out, producing less accurate parts and more extended periods under repair.

Cost is another important consideration when deciding to undertake this process. Although repairing a mold often costs less initially than replacing it, the company has repeatedly spent money on the mold’s repairs. It results in losses from the molecules during the repair process.

In the long run, it might be more than the cost of a replacement mold if this aspect includes the overall loss of production time and poor-quality molecules. If the cost of repairs gets closer or equal to 50-60% of the cost of a new mold, then it makes more sense to purchase a new mold instead. Moreover, if usage quantities are likely to increase or product layouts change, getting a new mold might be more cost-effective.

Conclusion

Injection mold repair is central to optimizing industry product quality and production rate. Molds are well maintained and repaired as soon as they break down to avoid high costs of replacement in case of a breakdown.

Manipulation of putty, blushing, and ejection pin maintenance reduces the amount of imperfections in the final products. It rectifies molds to suit their appropriate working conditions by welding, surface grinding, and replacement of components.

Finally, the decision to repair or replace a mold depends on some variables, including the degree of the worn mold and the impact of the repair or replacement on cost and productivity.