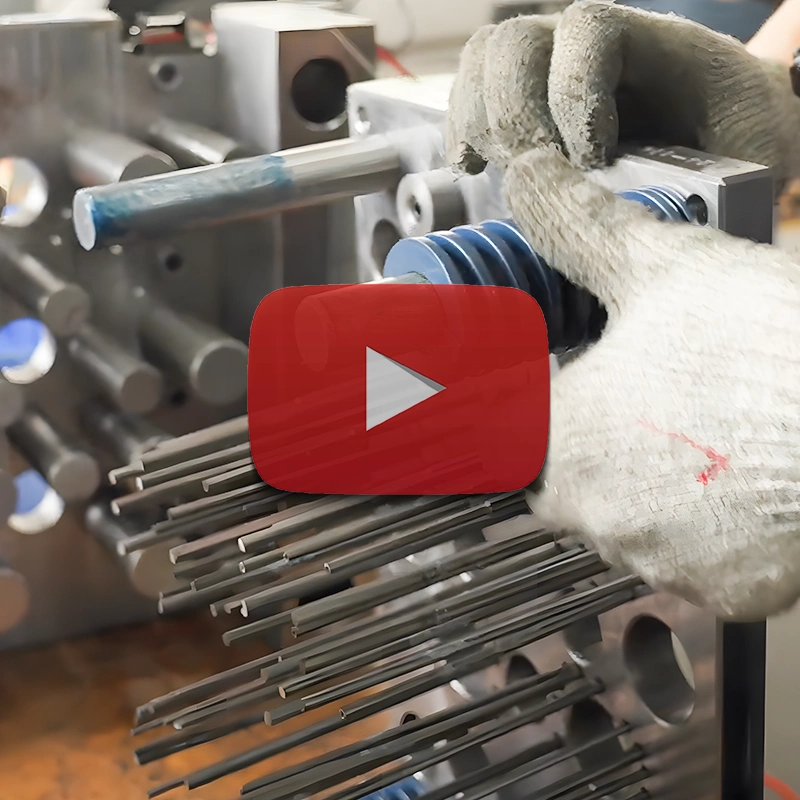

Mold fitting is an important part of making sure a mold works perfectly during production. It involves carefully aligning all the different parts of the mold to ensure they fit together just right. To get this done, technicians often use a die spotting press. This machine lets them close the mold in a way that’s similar to how it will be used in actual production, helping them spot and fix any issues before the mold goes into full use. By using a die spotting press, manufacturers can make sure everything lines up properly, leading to a smooth production process and high-quality finished products.