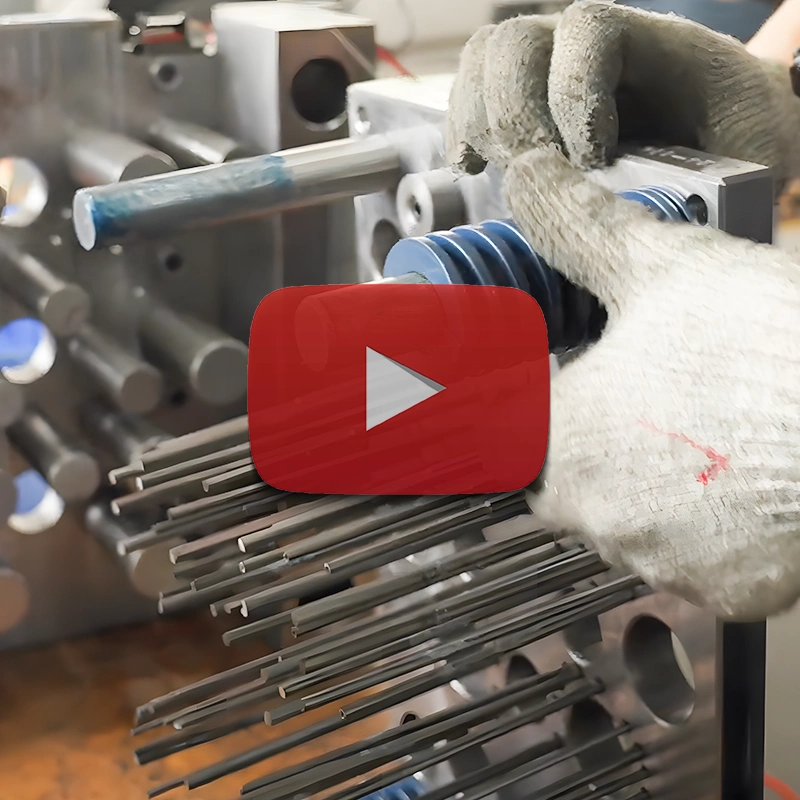

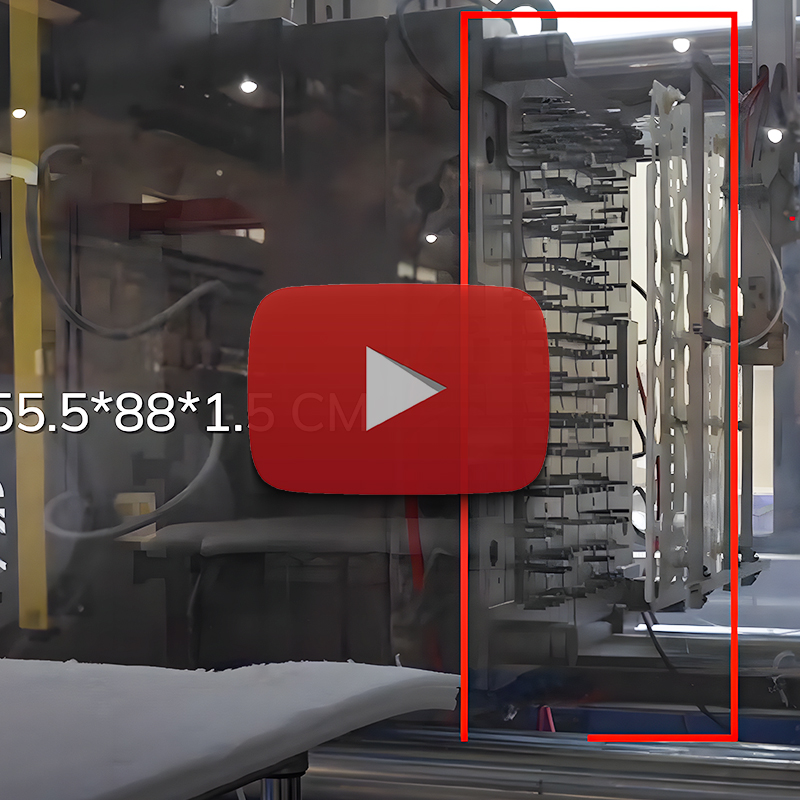

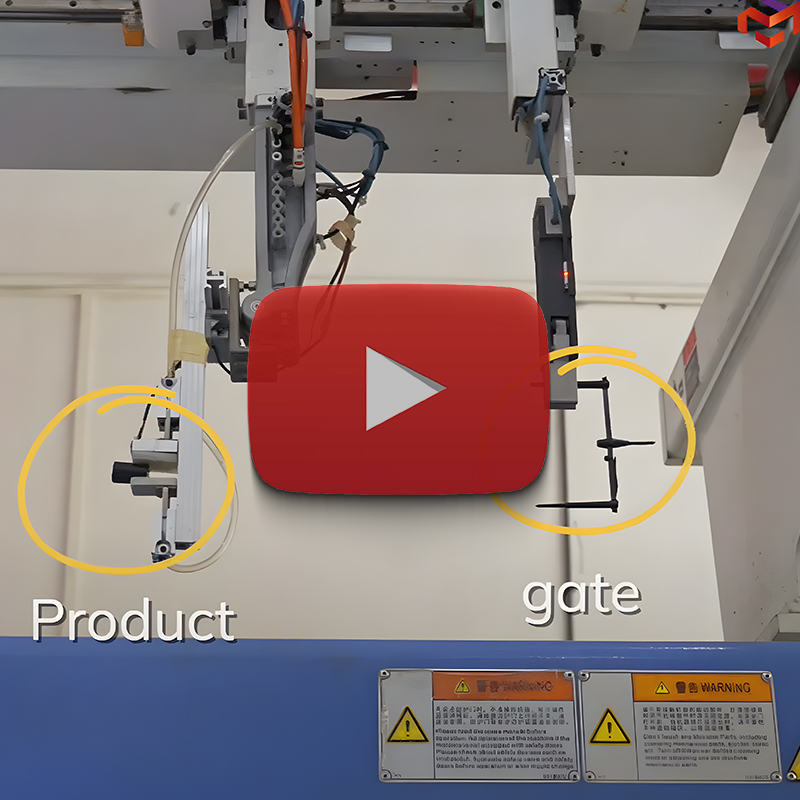

Micro and small parts injection molding is not easy because it demands a really high level of precision. The molds have to be spot-on, because even the tiniest mistake can mess up the final product. Working with such small parts also means you need special equipment and techniques to keep everything consistent and high-quality. On top of that, you have to carefully control the material flow and maintain an even temperature throughout the mold, since any little fluctuation can lead to warping or incomplete parts. All of this makes micro and small parts injection molding a challenging process that requires a lot of expertise and advanced technology to get right.