Injection molding is the backbone of modern manufacturing since it can make extremely high volumes of identical and precise plastic parts. But is it easy to maintain the precision when producing parts through injection molding? Not really!

Here’s why: the precision in the final product depends upon understanding and controlling injection molding tolerances. These injection molding tolerances are the dimensional changes that can take place in a part to function as intended.

In this article, we will take a closer look at what is injection molding tolerances, the influencing factors, and a number of recommendations on how to ensure your parts fall within specifications.

What Is Injection Molding Tolerances?

Injection molding tolerances are acceptable variances of specified dimensions that, if exceeded, will cause the molded part to not function or perform its operational expectation. These tolerances are important where molded parts are to form part of larger assemblies that require more demanding fits.

When the mold tolerance for a certain part is specified to be within ±0.005 inches, it means that the part can be more than or less than the specifications in its design by 0.005 inches and still be considered acceptable.

Why Are Tolerances Important?

Tolerances are important since they allow manufacturing molded parts to fit and function consistently. Poorly controlled tolerances lead to assemblies that don’t properly fit or function.

This could result in system assembly issues, performance failures, or even the rejection of entire production batches. Whereas, maintaining tight tolerances can help ensure product quality, improve efficiency, and reduce waste.

Types of Injection Molding Tolerances

Injection molding has a variety of tolerances related to the different dimensions and functionalities of parts. Understanding these tolerances provides the foundation for design and manufacture to meet certain requirements.

So, without any delay, let’s take a closer look at these tolerances.

Tolerancias dimensionales

Dimensional tolerances are the general limits to which a part’s overall size may vary. It helps ensure that parts fit together correctly in assemblies.

Suppose the dimensional mold tolerance for a part should be 100 mm ± 0.1 mm. In this case, for correct assembly, you can only use parts as short as 99.9 mm and as long as 100.1 mm.

General Factors Affecting Dimensional Tolerances

- Material Shrinkage: All the materials shrink at different rates in their cooling processes. This variation is usually incorporated during design and mold fabrication.

- Diseño de moldes: This includes the design of the mold and the positioning of the gate and runner system to determine the consistency of material filling in the mold and cooling.

- Process Parameters: These refer to controlling parameters that affect the general dimensional tolerances, including injection pressure, mold temperature, and cooling time.

Flatness and Straightness Tolerances

Flatness and straightness tolerances ensure that a part’s surfaces are in a state, which is important when parts must align with other flat surfaces or slide against each other.

It is also important for parts used in mechanical assemblies because even a slight deviation from flatness can cause the part to misalign and malfunction.

Common Challenges to Flatness

- Deformación: You can experience in a part if one section of a mold cools at a different rate than another, resulting in its distortion. It tends to happen with parts that have uneven wall thickness.

- Material Properties: Certain materials are more prone to warping than others. Materials with high shrinkage or anisotropic properties tend to warp more easily, meaning the property has different values in different directions.

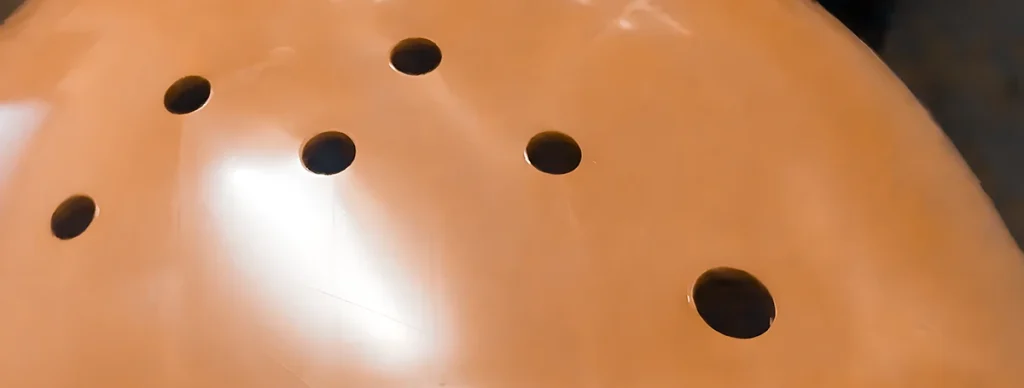

Hole Diameter Tolerances

Tolerance in hole diameters is important in parts containing holes, which are meant for accommodating screws, bolts, or pins. In most cases, such a type of tolerance is required since it accommodates shrinkage and flow characteristics of the material for the perfect fit.

Factors Affecting Hole Diameter Tolerances

- Material Shrinkage: In addition to the dimensional tolerances, material shrinkage is one of the key determinants of the hole’s final diameter.

- Design of Mold: The design and location of the core pins, which are usually responsible for the mold holes, may equally affect the final diameter when subjected to deflection or wear over time.

Tolerances for Concentricity and Ovality

The most critical tolerances of cylindrical parts are concentricity and ovality, where the round shape has to be maintained. In this context, concentricity describes how well the central axis of a cylindrical part coincides with a reference axis, while ovality describes the part’s roundness.

Concentricity and Ovality Maintenance

- Uniform Cooling: Parts can become ovate due to non-uniform cooling, which results in a cylindrical part losing roundness. In such cases, it is usually required that the cooling be uniform throughout for these tolerances to hold.

- Selección del material: Materials with low shrinkage and good dimensional stability are more appropriate for parts requiring tighter concentricity and ovality tolerances.

Factors Affecting Injection Molding Tolerances

Several of the factors mentioned below affect the tolerances that are achievable in injection molding. Understanding such factors is essential to designing parts that meet your tolerance requirements.

Selección de materiales

Material selection heavily influences tolerance due to the material’s inherent shrinkage characteristics.

For example, the general rule of thumb is that polypropylene parts will exhibit around 20% higher shrinkage than materials like ABS or polycarbonate. Thus, we should design the mold with this shrinkage to create parts within the set tolerances.

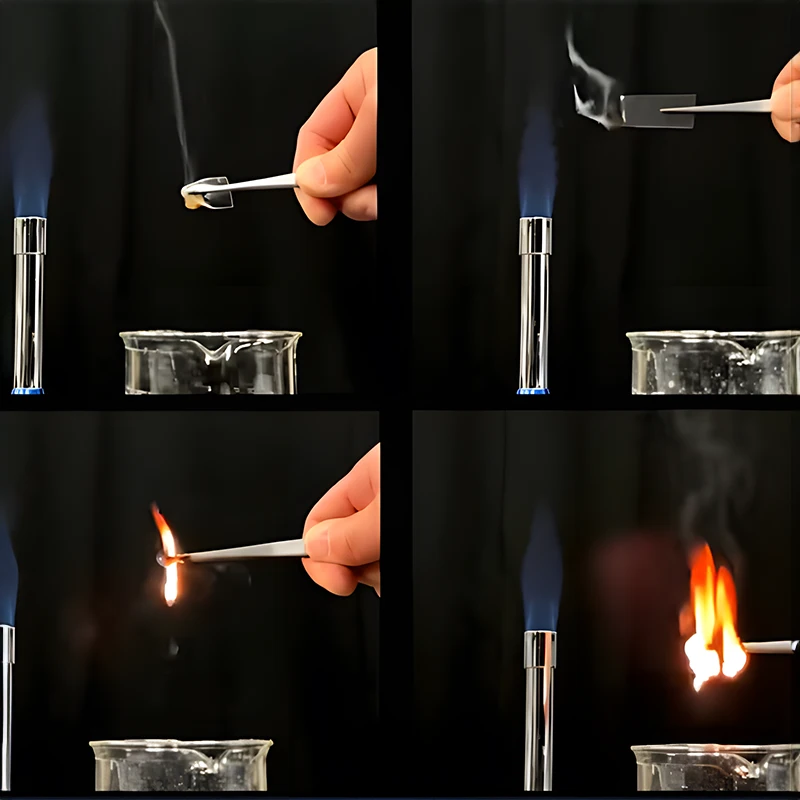

Shrinkage Rates

In a normal datasheet, shrinkage rates differ for different materials. For instance, ABS shrinkage rate can fall between 0.4 and 0.7%, whereas polyethylene can fall between 1.5 and 4%.

This knowledge of mold tolerance helps during mold design, helping you ensure that the mold will produce parts within specified tolerances.

Part Design

Mold tolerance control is all about designing your parts correctly. Here are some key factors in designing:

- Espesor de la pared: Uniform wall thickness is important to maintain dimensional stability. The thicker a wall is, the more likely it is to cool unevenly, resulting in variations of shrinkage in different areas of the part that will throw overall dimensions out of tolerance.

- Draft Angles: Adequate draft angles are essential in general. These normally range from 1 to 2 degrees to enable the parts to be ejected from the mold easily without damaging the dimensions. An inadequate draft leads to parts sticking inside the mold and hence, dimension variations become important.

- Feature Complexity: Complex features like deep pockets or thin walls can be difficult to mold in tight tolerances. Simplifying these features or designing them considering the mold tolerance control will enhance the precision of the final part.

Tooling Considerations

The design and quality of the mold itself are critical in determining the tolerances that can be achieved. Let’s explore why:

- Mold Material: The material of the mold will impact its durability and precision. For example, molds made from steel hold tighter mold tolerances for more cycles than molds made from aluminum.

- Diseño del molde: The mold design profile of runners, gates, and cooling channels affects the material’s uniformity of filling and cooling. Poor design leads to a lack of uniform cooling and shrinkage that can push the part out of tolerance.

- Tool Maintenance: The mold must undergo routine maintenance to ensure tight tolerances. Molds that have been used beyond their capacity can cause dimension inaccuracies because they may not be able to hold the material as well in the intended shape.

Process Controls

Several variables involve the injection molding process in affecting part tolerances, including:

- Presión de inyección: Consistent injection pressure provides proper material filling in the mold and helps maintain dimensional accuracy. Variations in pressure cause parts to appear in different sizes from cycle to cycle.

- Control de la temperatura: Precision in the temperature of mold and material is very important. This is because viscosity variation with temperature will make all the difference in flowing into a mold and its cooling, hence tolerances.

The time spent cooling the part in the mold itself affects the final dimension, which is usually determined by cycle time. If the cycle times are shorter, parts may get ejected before they fully cool, so they shrink more after ejection and can present potential mold tolerance problems.

Best Practices to Achieve Tight Injection Molding Tolerances

Several factors in design and manufacturing are to be considered to achieve tight tolerances in injection molding.

Following are best practices that can ensure your parts will meet their requirements for tolerance:

1. Design for Manufacturability

Integrate DFM principles right from the beginning of the design cycle to avoid costly redesigns later on. That is, one must ensure uniform wall thickness and appropriate draft angles and simplify all those complex features that are difficult to mold accurately.

Example: For components featuring variable wall thickness, consider adding support ribs in areas of thinner walls to reduce warping effects and maintain dimensional stability.

2. Material Selection

Choose materials that can easily achieve the part’s required tolerances. This may include thermal expansion, shrinkage rate, and mechanical property considerations of the material. Consult with material suppliers or molding experts on choosing the right material to yield the intended tolerances.

Example: Suppose your part requires high dimensional stability. Then the materials with lower shrinkage, such as polycarbonate, may be more suitable than more highly shrinking materials like polypropylene.

3. Precision Tooling

Invest in quality tooling, and have the mold designed and built to tight tolerances. CNC machining on high-quality and properly designed mold will help ensure accurate dimensions. Moreover, hardened steel molds can provide long life and repeatable part-to-part quality.

Example: A steel mold with designed cooling channels and optimal gate placement will help hold tight tolerances for high-volume production.

4. Process Optimization

Use robust process controls to sustain, monitor, and vary temperature, pressure, and cycle time. You can also employ sensors inside the mold for real-time feedback to enable adjustments during molding, ensuring consistent part quality.

Example: Employ scientific molding techniques in analyzing the fill, pack, and hold stages of the process to ensure that each part has minimum variation.

5. Scheduled Maintenance and Quality Checks

Regularly inspect and maintain molds to prevent wear and tear, a primary cause of tolerance issues. It is also important to implement quality control measures, such as dimensional inspections and statistical process control. This will assist in finding any deviations early to make timely corrections.

Example: Schedule maintenance regularly to clean and inspect the mold, looking for any signs of wear that might affect the part’s dimensions.

Common Issues in Maintaining Injection Molding Tolerances

Even with one’s best efforts, there are several instances in which maintaining tight tolerances is not that easy in injection molding. Common ones among them include:

- Material Variability: Different batches of the same material can slightly vary shrinkage and flow properties, leading to inconsistencies in part dimensions.

- Complex Part Geometry: Parts with complex shapes, thin walls, or deep cavities are most prone to warping and variation in dimensions.

- Ambient Temperature and Humidity Variations: Variables like ambient temperature and humidity changes can affect molding, which may affect materials susceptible to moisture absorption.

- Tool Wear: Molds will wear out over time, producing less accurate parts. To keep tolerances tight, regular maintenance and timely replacement of worn-out molds are necessary.

Conclusion: Meeting Injection Molding Tolerances with Accuracy

Injection molding tolerances are the centerpiece of high-quality plastic part manufacturing, meeting very strict part requirements.

Understanding the key elements that influence tolerances, including material selection, part design, tooling quality, and process controls, will help make parts with the precision needed in applications found in various complex assemblies.

The best practices to achieve tight tolerances with your injection molded parts include design for manufacturability, appropriate material selection, and consistent process controls. It ensures the proper function, fit, and quality of your products.

Ready to optimize the injection molding process? Our specialists at First Mold can guide you through the complexities of mold tolerance management, offering parts exactly according to your specifications.