Black oxide and phosphate coating are significant material science technologies that improve metal properties. Manufacturers apply these technologies to enhance the chemical properties of materials.

For instance, metal corrosion is one of the challenges affecting plant engineers and submarine vessels, especially those operating in salty environments. Manufacturers use these technologies to develop corrosion-resistant materials useful in designing such machines.

In addition, aesthetic appeal in the manufacturing industry has attracted wider black oxide and phosphate coating applications. While the two technologies serve similar purposes in protecting materials against corrosion, the technology behind each process differs. Further, the two processes have different applications in the industrial, aerospace, and part manufacturing sectors.

Black Oxide Coating Process

The black oxide coating is a conversation coating process that enhances corrosion resistance and aesthetic appeal to ferrous materials like iron and steel. The process converts the surfaces of the iron products to magnetite. This conversation leads to the dark black surface maintaining the mechanical properties of the materials and the dimensions.

The black oxide coating is a multi-stage process that includes material cleaning, coating application, rinsing, and post-treatment.

Cleaning

Cleaning is the initial step of black coating and determines the effectiveness of the coating material application. This step removes oils and grease, dirt and dust, surface rust, oxides, and scales from the material surfaces. This contamination can act as a barrier between alkaline solution and metal. Rust is common in ferrous materials, and cleaning it helps to prevent the creation of voids and weak spots in the resulting coating surface.

Manufacturers employ different methods to clean the surfaces.

The first method is degreasing the materials. In this technique, solvent-based degreasers like hydrocarbon solvents dissolve and remove organic contaminants, oils, and grease from the material surface. Degreasing occurs in industries such as immersion tanks or vapor.

The second cleaning technique is the alkaline solutions. Alkaline solutions like potassium hydroxide (KOH) and sodium hydroxide (NaOH) emulsify oils, making cleaning easier.

Material cleaning operators can also use abrasive blasting to remove the dirt from the material surfaces mechanically. This process is effective in removing mill scale and oxides. Some abrasive particles include aluminum oxide, sand, and glass beads.

Acid pickling is an effective cleaning technique, particularly for materials with heavy oxidation and rust. However, for sensitive materials, over-aggressive acid pickling may cause damage to the surface. In such cases, alternative methods like mild mechanical or chemical cleaning may be preferable.

It also helps to reduce corrosion resistance and prevent inconsistent coating.

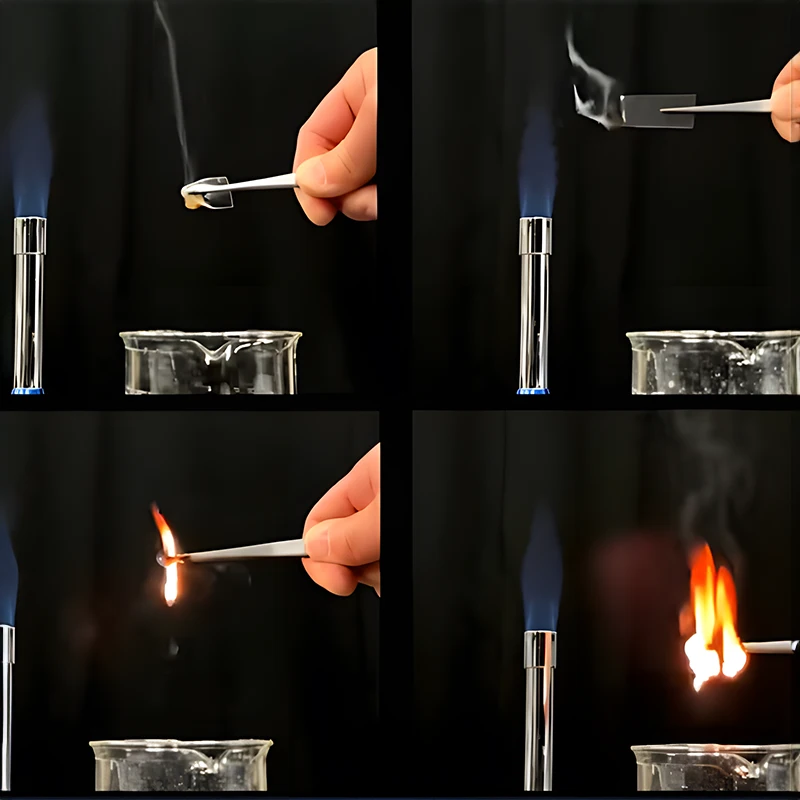

Aplicación

The application involves immersing metal material in a hot alkaline solution with oxidizing salts. The application occurs in an alkaline bath with alkaline solutions. The alkaline bath includes sodium hydroxide and oxidizing salts like sodium nitrite (NaNO2) and sodium nitrate (NaNO3). Operators keep the bath temperatures between 1400C and 1600C for an effective chemical reaction.

A chemical reaction between metal and bath solution leads to the formation of magnetite (Fe3O4). This product is a black crystalline compound covering the metal surface.

The magnetite layer is thin, ranging from 0.5 to 2.5 microns. Even though it’s very thin, this layer offers high resistance to wear and corrosion.

The effective coating process depends on several factors. First, the balance of alkaline salts and the concentration of oxidizing salts determine the quality of magnetite. The immersion time can determine the state of the coating. Very short immersion time can leave the metal with partial coating. The immersion time should be between 5 and 30 minutes. The longer the immersion time, the thicker the black coating.

However, the black coating becomes self-limiting. This limit implies that a longer immersion time does not guarantee more coating. Temperature regulation also determines the black oxide applications. Too low a temperature may cause incomplete conversion to the magnetite. On the other hand, temperatures that are too high may degrade the quality of the layer.

Rinsing

Rinsing ensures that the product is of high quality and durable. The rinsing process removes residual chemicals from the alkaline bath. Proper rinsing in the black coating process eliminates surface imperfections and poor performance of the oxide layer. Operators apply different methods to rinse the material. The first and most common method is water immersion rinse. It involves immersing parts in a water bath to dissolve and wash away residual chemicals. In an industrial setting, rinsing occurs in multiple rinsing tanks, with every rinsing step including cleaner water.

For delicate and small parts, manufacturers use spray rinsing. Jets of water spray over the conveyor belt or basket with the parts of the material from black oxide applications. This process is faster than immersion rinsing and ensures proper cleaning of all surfaces, including crevices. Manufacturers also used deionized water rinse, especially for parts that require the highest quality and corrosion resistance measures.

Post-treatment

This last step enhances coating properties and extends the lifespan of the treating component. Beyond basic black oxide layer provisions, manufacturers apply oil and wax to add more benefits to the metal component. The four types of post-treatment include oil treatment, wax treatment, acrylic or polymer sealants, and dry film lubricants. Industrial oil helps to provide lubrication, leading to corrosion and wear resistance components. This method involves dipping the metal into an oil solution or spraying the solution onto the metal. The oil penetrates the black oxide layer, creating a protective seal. The choice of oil depends on the material under oxide coating and the intensity of the purpose in the industrial application.

Manufacturers use wax coating for aesthetic use. Wax leads to a uniform finish. A metal dips in the molten wax bath. Sometimes, the wax sprays on the part, creating a smooth surface. Acrylic or polymer sealants are essential for providing higher protection levels. This sealant creates a durable and tougher layer that is wear and corrosion-resistant. This type of treatment is useful for parts operating in extreme environments like the engine piston.

Dry film lubricants are applied in high-performance and precision parts. Operators in clean environments prefer this type of post-treatment because they do not mess with the oils or waxes.

While selecting the post-treatment process, key considerations include environmental exposure and reapplication. For example, heavier oil treatment best suits highly humid environments. Wax or dry film best suits aesthetic and indoor applications. In some cases, reapplication of post-treatment may be necessary, especially for oil-treated parts, to continuously enhance lubrication. For example, post-treatment of engine parts will require the reapplication of oil lubricants after some time.

Phosphates Coating Process

Phosphate coating converts metal surfaces to form insoluble phosphates for metal surface protection. The resulting phosphate surface offers wear and corrosion resistance properties to the metal. The phosphate coating process includes cleaning, activation, application, rinsing, and sealing.

Cleaning

The cleaning process removes possible contaminants from the metal surface. It is similar to the black oxide coating process. The cleaning agents include alkaline solutions, acidic solutions, and degreasing agents.

Activation

After cleaning, manufacturers expose the metals to specific chemicals to enhance better crystal formation during phosphate application. The process creates several nucleation sites for the growth of phosphate crystals. These nucleation sites lead to even crystal structure on the material surface. During activation, operators apply colloidal titanium salts on the clean metal surface, forming a thin layer. This layer catalyzes phosphate reactions to occur at different points across metal surfaces.

Phosphate Application

During this process, operators immerse metal parts in hot phosphoric acid and other chemicals. This process produces a chemical reaction between metal and phosphoric acid, forming an outer crystalline coating. The resulting layer is corrosion-protective and improves paint adhesion.

The process starts by submerging a clean, activated part in a hot phosphoric acid bath. The bath includes other chemicals such as iron, zinc, and manganese metal salts. The temperature of the bath typically ranges from 60°C to 90°C for zinc phosphate coatings, while manganese phosphate coatings may require higher temperatures, often ranging from 90°C to 98°C, depending on the specific application.

Consequently, a metal phosphate surface becomes insoluble in water and strongly bonds to the metal. Depending on the metal salts, different crystalline layers form from this process. Some phosphates include zinc phosphate, iron phosphate, and manganese phosphate. For example, the following reaction can lead to zinc phosphate.

Rinsing

The rinsing process helps to remove excess chemicals, including unreacted metal salts. Rinsing is essential to prevent surface contamination and prevention of corrosion. In some cases, sealing is necessary after rinsing to enhance the durability of phosphate coating. Possible sealing techniques include oil sealing, chromate sealing, organic sealants, and wax sealants.

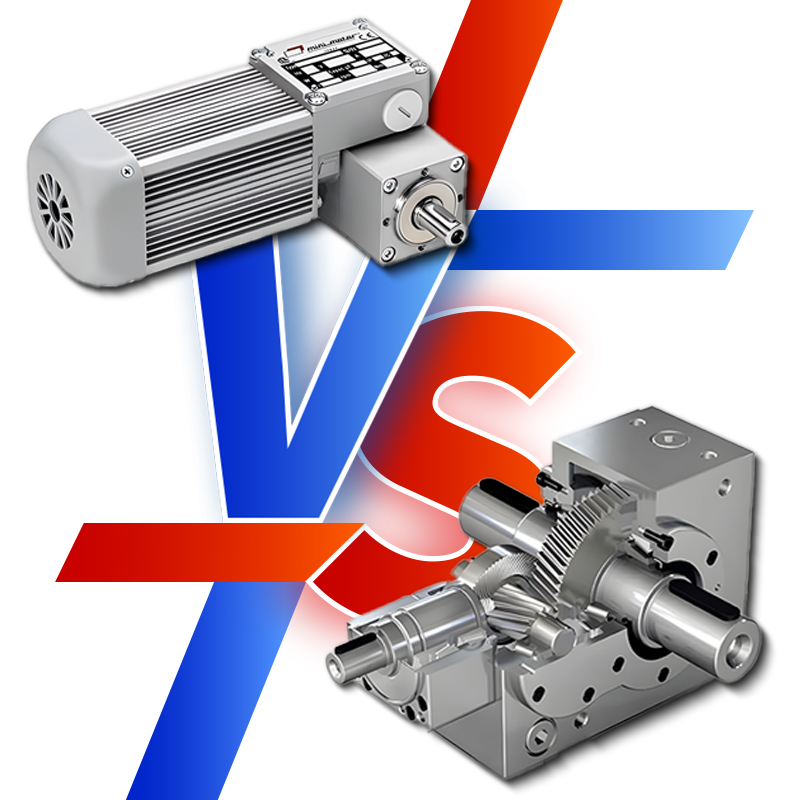

Comparison between Black Oxide Coating and Phosphate Coating

| Aspecto | Black Oxide Coating | Phosphate Coating |

| Composición | Iron oxide (Fe3O4) layer formed on the surface of the metal | Zinc, manganese, or iron phosphate layer |

| Primary Purpose | Aesthetic finish, mild corrosion resistance, lubricity | Corrosion protection, base for paint or other coatings |

| Corrosion Resistance | Mild corrosion resistance (needs oil or sealant for protection) | Moderate to high corrosion resistance depending on the type (zinc provides better protection) |

| Acabado superficial | Dark black or blue finish, smooth and glossy | Matte or satin finish, rougher texture |

| Espesor | Thin layer (0.0002 to 0.0006 inches) | Thicker layer (0.0002 to 0.002 inches depending on type) |

| Wear Resistance | Moderate, often enhanced with additional oils or waxes | Good wear resistance, especially with manganese phosphate |

| Resistencia a la temperatura | Good thermal stability typically withstands up to 500°C | Lower heat resistance, sensitive to high temperatures |

| Adhesion Properties | Excellent adhesion to paint or oils | Excellent base for painting and further coatings |

| Application Methods | A chemical bath or hot alkaline solution | Immersion in a phosphate solution (dipping) |

| Coste | Generally lower cost than phosphate coating | Higher cost due to thicker layers and process complexity |

| Lubricity | Provides lubricity when combined with oils or waxes | Good lubricity, especially with manganese phosphate |

| Impacto medioambiental | Less environmentally friendly, may involve hazardous chemicals | It is less dangerous than black oxide but requires water treatment for waste |

| Aplicaciones comunes | Tools, firearms, machine parts, fasteners | Automotive components, industrial machinery, parts for painting |

| Base Materials | Mostly ferrous metals (steel, iron) | Ferrous and non-ferrous metals, including aluminum and zinc |

Aplicaciones industriales

Both black oxide and phosphate coating are necessary in the industrial setting to enhance metal surface strength.

Common Black Oxide Coating Uses

Black oxide coating improves the aesthetic appearance of the final product and corrosion resistance. Different industries, like manufacturers of engine blocks, use black oxide technology to manufacture parts that require high lubricity levels and mild corrosion.

For instance, the manufacture of fasteners like screws, bolts, and nuts requires thin coating for resistance coating. The automotive and aerospace fields use this technology to produce black oxide-coated parts. Producing firearms is also a signification of black oxide because it prevents rusting.

Sometimes, the riffles stay longer without use, requiring protective measures against rusting. The cutting tools also need a black oxide coating to minimize wear during operation. The black coating technology is also necessary for aesthetic applications for electronics manufacturing, attracting high purchasing power.

Common Applications of Phosphate Coating

Different phosphates have different industrial applications. For example, in automotive engineering, zinc phosphates help coat engine components, frames, and car body panels.

Military use manganese phosphate to protect equipment and hardware like armor and vehicle components. These components offer high resistance capabilities and are corrosion-resistant. Manganese phosphate coating helps manufacture machinery like gears, bearings, and camshafts in industrial applications. These coatings lead to low friction cases, prevent wear, and retain lubricants in high-stress conditions.

Manufacturers also utilize phosphate coating to manufacture home appliances like refrigerators, washers, and dryers for paint adhesion. Further, the phosphate coating in these appliances provides high resistance, making the products last longer.

Conclusión

Black oxide and phosphate coating are significant material science technologies that improve metal properties. The black oxide coating is a conversation coating process that enhances corrosion resistance and aesthetic appeal to ferrous materials like iron and steel. The black oxide coating is a multi-stage process that includes material cleaning, coating application, rinsing, and post-treatment.

Phosphate coating converts metal surfaces to form insoluble phosphates for metal surface protection. The phosphate coating process includes cleaning, activation, application, rinsing, and sealing.

Different industries, like manufacturers of engine blocks(check engine parts manufacturing case), use black oxide technology to manufacture parts that require high lubricity levels and mild corrosion. Different phosphates have various industrial applications. For example, in automotive engineering, zinc phosphates help coat engine components, frames, and car body panels. Different phosphates have different industrial applications. For instance, in automotive engineering, zinc phosphates help coat engine components, frames, and car body panels.