CNC Protoyping Service

Bridges the gap between concept and reality with CNC Power.

- Efficient for both small and large parts

- Adaptable to modifications and iterations

- Supports tight tolerance requirements

- Complex geometries achievable

Tightest Tolerances Among All Rapid Prototyping Process

The process of making prototypes through CNC machining is known as CNC prototyping. This is currently the most commonly used process among all prototyping processes at FirstMold. Although it is not as fast as 3D printing, it offers the highest precision, achieving tolerances of ±0.005mm.

We possess a complete set of advanced prototype processing equipment, including precision engraving machines, lathes, milling machines, and imported five-axis CNC machines. We specialize in automotive prototypes, aircraft prototypes, medical prototypes, and hardware prototypes, pushing the limits of speed and precision to the utmost, serving thousands of diverse clients.

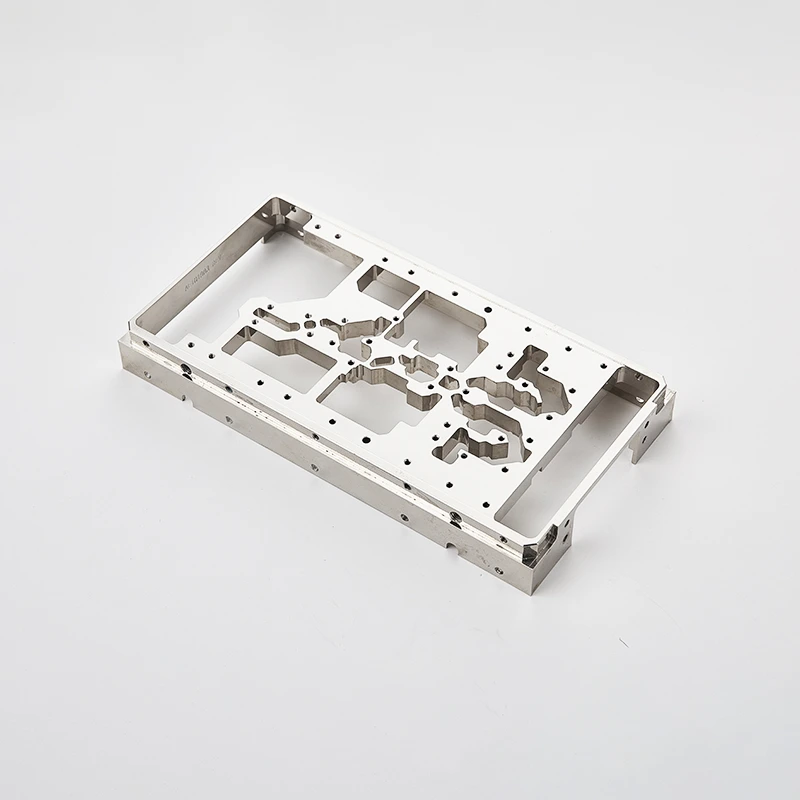

CNC Prototypes Gallery

Throughout our more than ten years of CNC prototyping experience, we have manufactured a large number of functional CNC prototypes, aesthetic or visual CNC prototypes, rapid tooling CNC prototypes, proof-of-concept CNC prototypes, fit and assembly CNC prototypes, and user experience CNC prototypes.

- Delivery within five days

- Multiple confidentiality measures

Elevate Your Designs with a Click

FirstMold's Advantages On CNC Prototyping Service

Flexible Tooling and Design Adaptability

No need for complex tooling. If there is a need to change the shape and size of a part, only the machining program needs to be modified, which is suitable for the development and modification of new products.

Stable Quality and High Precision

FirstMold's prototype processing is stable in quality, with high machining precision and high repeatability, meeting the processing requirements of high-precision products.

High Production Efficiency

In the case of mass production, our production efficiency is relatively high, which can reduce the time for production preparation, machine tool adjustment, and process inspection.

Complex Surface Machining Capability

Our CNC prototyping service can process complex surfaces that are difficult to handle with conventional methods, and even some processing parts that cannot be observed.

CNC Prototyping Workflow

Submit Your Drawings and Requirements

Rapid Response and Contract Agreement

Part and Assembly Drawing Analysis

Material and Shape Selection

CNC Prototype Programming

Machining Allowance and Process Dimensioning

Equipment and Tool Selection

Cutting Parameters and Labor Quota Determination

Main Process Specifications and Inspection Methods

CNC Prototyping Process

On-time Delivery

CNC Prototyping Workshop At FirstMold

- GF+ Milling Centers

- Haas 5 axis Machining Shops

- Makino EDM Series

- Mirrordick EDM Series

4 Prototoyping Workshops

A Haas brand CNC machine shop, a GF+ high precision CNC workshop, a mill & lathe workshop, an EDM workshop.

Two departments, four teams

Two departments are divided into four groups according to the industries they are responsible for.