Rapid Prototyping Service

Optimize your designs and reach product to production effortlessly

- Various shapes and tight tolerance up to ±0.02mm

- Diversified material selection for CNC prototyping, 3D printing, and vacuum casting

- Expert one-on-one service

Metal or Plastic

Precision Rapid Prototype Customization Center

- Metal prototypes

- Plastic prototypes

- Medical prototypes

- Electronic prototypes

- Robotics prototypes

- Automotive prototypes

- Appliance prototypes

- Sheet metal prototypes

Main Rapid Prototyping Services At Firstmold

High stability and good surface quality, capable of quickly and accurately producing samples similar to the final product.

Prototype in Hours, Not Weeks

FirstMold's Capabilities On Rapid Prototyping

Multi-material customization available

With high quality raw materials and strict control, we support different properties of resin consumables such as opaque, transparent, high temperature resistant, and high strength to meet the needs of customers in various industries for material properties in all aspects.

Post Processing

Rapid prototypes in Firstmold are polished through multiple processes and profiles are cut in one piece to meet your needs. Complex, difficult surfaces and functional structures can be quickly formed with high precision.

Resource allocation advantages

We have a variety of processing methods and strict product confidentiality with tight tolerance up to ± 0.02mm. The surface of the finished product is flat and smooth, the processing process pays attention to details, prototypes are strong and not easy to damage.

Our 4 advantages, only to polish the art-grade prototype

One Stop Prototype making experience

- We're a professional precision prototypes making technology enterprise

- Our Factory area reaches 30000 square meters, with more than 200 employees on staff

Product Safety Guarantee

- A variety of materials to choose from for the product

- Strictly in accordance with industry standards to ensure product versatility and stability

- Provide a full set of "design verification to on-demand manufacturing" solutions for various industries with innovative designs

Professional process technology

- We have all-round and exquisite production technology to create high-quality prototypes

- We have the development ability to provide quality assurance products for our customers

- Prototypes can be customized according to customer needs

Provide a caring after-sales service experience

- Firstmold has a mature technical development team to answer your question

- We provide you with free technical support

- Deep cooperation with major logistics to ensure rapid delivery of goods

Processing capacity display

FAQs For Overmolding Services

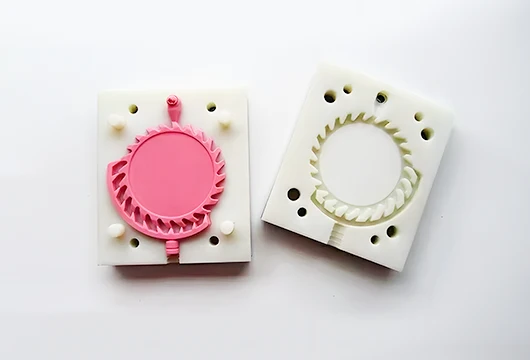

Overmolding is a process where two or more materials are combined to create a single part. It involves molding a layer of material over a previously molded part to add functionality, durability or aesthetic appeal.

Overmolding can be done with a variety of materials, including plastics, rubbers, metals, and more. At Firstmold, we use a range of thermoplastics and thermoset materials for overmolding.

Overmolding can add a variety of benefits to a part, including improved functionality, better grip, increased durability, and aesthetic appeal. It can also reduce the need for additional assembly steps and minimize the number of parts needed.

Overmolding is commonly used for parts that require added functionality, such as handles, grips, seals, and buttons. It is also used for parts that require protection or insulation, such as electronic components.

Overmolding involves molding a layer of material over a previously molded part, while two-shot molding involves molding two different materials simultaneously into a single part. Overmolding is typically used for parts with simpler geometries, while two-shot molding is used for more complex parts.

At Firstmold, we have a rigorous quality control process in place to ensure the highest standards of quality. We use advanced equipment and techniques to test and verify the integrity of each part, and we work closely with our clients to ensure their specifications are met.