PEEK (Polyetheretherketone) Injection Molding

The most powerful yet most expensive plastic solution.

- Withstand the extreme environments, no fear for high temperatures and aggressive chemicals

- Less maintenance and downtime for products involving movement or friction

- Ideal for critical parts in industries where structural integrity is paramount

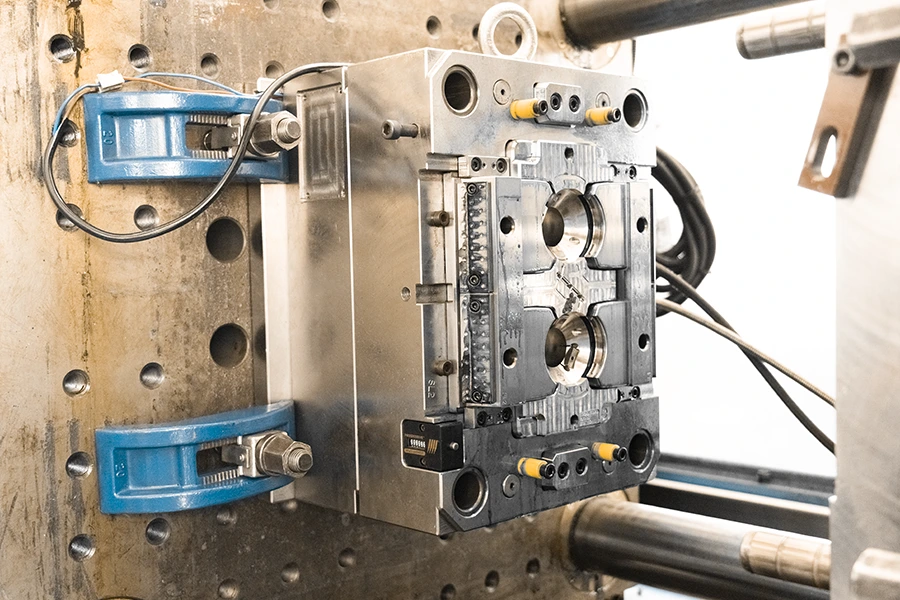

PEEK High-End Part Injection Molding Factory

The high-temperature processing of PEEK may not be suitable for all injection molding part suppliers, as it places high demands on injection molding capabilities. FirstMold, with hundreds of case applications of PEEK material, is well-versed in the properties of PEEK and has substantial practical production experience. Our high-performance machines, knowledgeable professionals, and experienced mold design engineers perfectly match these requirements.”

Applications of PEEK Injection Molding

PEEK, with its creep resistance, ability to withstand various liquid media, and high-temperature resistance, becomes an almost perfect material. However, considering its high cost, it is therefore extensively used in special structural components and performance parts.

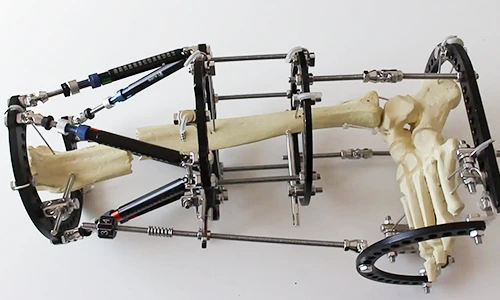

医疗

- Dental Implants

- Orthopedic Implants

- Endoscopic Components

- Surgical Retractors

- Catheter Tips

- Medical Pump Components

- Electrosurgical Tools

航空航天

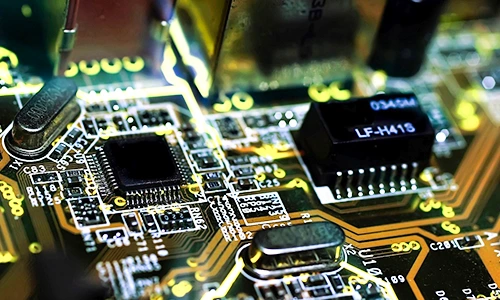

- Connector Housings

- Printed Circuit Board (PCB) Supports

- Sensor Housings

- Light Emitting Diode (LED) Mounts

- Relay Components

- Cable Insulation

- Wearable Device Components

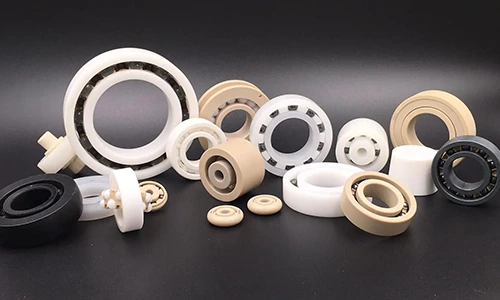

Machinery and Equipment

- Valve Seats

- Seals and Gaskets

- Bearings and Bushings

- Gear Wheels

- Piston Parts

- Slide Rails

- Shaft Sleeves

Electronic

- Fuel System Components

- Electrical Connector Bodies

- Aircraft Door Components

- Landing Gear Parts

- Thrust Reverser Components

- Aircraft Fasteners

- Actuator Cases

The development of AI has accelerated the arrival of the era of robotics. By adopting lightweight materials without sacrificing the original structure and performance, robots can reduce operational energy consumption. Among these materials, PEEK will fully demonstrate its remarkable abilities in this field.

聚丙烯

PE

个人电脑

聚氯乙烯

ABS

PA

POM

PBT

PMMA

PEEK

When Do You Start To Molding PEEK?

Our first PEEK injection molding case dates back to August 2014, involving a relatively simple automotive clutch gear seal ring product.

How Many Cases Have You Completed?

We receive 20-30 PEEK project requests from clients every year, ranging from simple gear molding to complex aerospace specialty performance parts.

What Parts Manufacturing Solutions Do You Offer?

We offer PEEK standard injection molding, PEEK insert molding, PEEK overmolding, PEEK family molding and even PEEK CNC machining solutions.

Why Choosing Our PEEK Injection Molding Service?

Choosing us for PEEK injection molding is a good decision that brings numerous advantages to your projects:

- High-performance machines are tailor-made for PEEK injection molding's stringent demands

- Our expert team, including seasoned engineers, is well-versed in overcoming PEEK molding challenges.

- FirstMold offers comprehensive PEEK molding services, from design and fabrication to post-processing and assembly.