ABS Injection Molding Services

Leading the Way in Advanced ABS Molding Solutions.

- Crafting Perfect ABS Parts for Your Projects.

- High-Tech ABS Molding for Your Most Detailed Designs.

- Fast-Track Your ABS Ideas from Sketch to Shelf.

- Custom-Crafted ABS Solutions, Designed to Your Exacting Standards.

Precision ABS Molding Solution By First Mold

At FirstMold, we bring precision to life with our expert ABS injection molding services. Whether it’s a sleek gadget or a durable household item, we craft every piece to perfection, ensuring quality that lasts. Trust us to turn your design into reality with accuracy and care.

Tips: If you’re new to ABS material, simply click ‘ABS Plastic‘ to learn more.

Diverse Applications of ABS Injection Molding in Industries

ABS plastic fabrication’s applications span various industries due to its durability, strength, and aesthetic appeal.

Automotive & EV

- Dashboard panels

- Air vents

- Instrument clusters

- Interior trim

- Bumper covers

- Door handles

- Mirror housings

Consumer Electronics

- Smartphone cases

- Tablet back covers

- Laptop housings

- Remote controls

- Console bodies

- Mouse shells

- Monitor stands

医疗设备

- Diagnostic devices

- Monitors Casing

- Portable Machine

- Surgical handles

- Inhaler components

- Insulin pens

- Instrument housing

Home Appliances

- Kitchen Appliances

- Blender bases

- Microwave door panels

- Vacuum cleaner casings

- Robotic cleaners

- Shaver housings

- Coffee machine bodies

聚丙烯

PE

个人电脑

聚氯乙烯

ABS

PA

POM

PBT

PMMA

PEEK

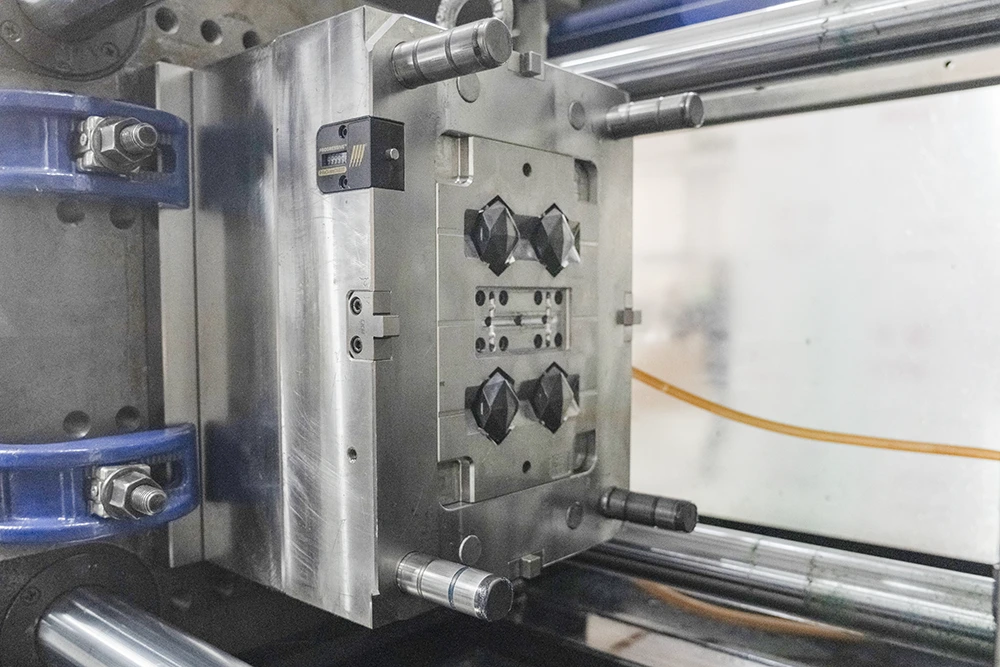

Our ABS Plastic Parts Production Capabilities

At FirstMold, our advanced facility is equipped with a comprehensive array of injection molding machines, perfectly suited for ABS plastic production. This infrastructure underpins our commitment to precision and flexibility in our ABS molding services. Our team’s deep expertise in ABS allows us to harness the latest technologies to create robust and top-tier components for a wide range of applications.

Custom Material Solutions

Recognizing the diverse needs of our clients, we specialize in modified ABS injection molding. By altering material properties such as impact resistance, flame retardancy, or UV stability, we tailor ABS to your specific application requirements.

Sector-Specific Expertise

Our ABS composite molding is used for a lot of different industries, for example, automotive, healthcare, consumer electronics, and so on. These include automotive components, medical devices and products that have good aesthetic and functionality.

Mold, Finish, & Quality

Our integrated approach includes in-house mold design and fabrication, advanced finishing techniques, and rigorous quality control, ensuring precision, aesthetic excellence, and unmatched quality in every ABS plastic fabricated part.

Key Advantages of Choosing FirstMold for ABS Molding

Through the various features of ABS injection molded parts, we can easily understand the multiple advantages of ABS injection molding.

- Durability and Precision: ABS plastic fabricated parts provide the necessary impact resistance, dimensional stability, and precision required for components like dashboards and bumpers, durable casings and intricate components.

- Aesthetic Versatility: These parts can be finished to a high-quality appearance, suitable for toys and appliances that require an attractive look, as well as healthcare devices where functionality combines with user-friendly design.

- Cost-Efficient Production for High-Volume Industries: The ease of processing and recyclability of ABS make it ideal for industries like construction and packaging, where cost efficiency and the ability to produce large quantities of durable, precise parts are critical.

According to statistics, ABS material has the highest usage rate in all injection molding projects at FirstMold.

ABS Injection Molding Cases

Custom ABS molding demands meticulous drying and process control to mitigate moisture-related defects, warping, and shrinkage, alongside precise mold design to ensure quality finishes and part integrity. Accordingly, engineering and technology that possess the necessary engineering and advanced machinery skills are required.

Precision ABS injection molding service with small challenges to produce high-quality luggage scale components.

It is a combination of plastic and aluminum materials that are processed through injection molding and mold-making processes. One of the most important factors in the production of Interior LED Lamp is the design and manufacture of its components, particularly the reflector and lens.

A simple case of mass production of portable ECG monitor buttons with a wide range of injection molding applications in the medical industry.

Explore FirstMold's manufacturing service in producing calculator housings with injection molding ro discover how the parts be made.

Overmolding a visually stunning and functionally precise perfume cap presented a unique challenge. Let's check a case of the cometics.

ABS Injection Molding FAQs

What are the advantages of FirstMold's ABS injection molding services?

FirstMold’s ABS injection molding services have several advantages. First, we have an experienced technical team with extensive injection molding experience and professional skills. They are capable of selecting suitable 注塑材料 based on customer requirements and product characteristics, and use advanced injection molding processes and technologies. Secondly, we focus on details and quality, maintaining strict quality standards at every stage from raw materials to the production process. Additionally, we prioritize communication with clients, responding quickly to their needs, and providing professional advice and solutions.

Our ABS products have environmental requirements. How do you ensure the ABS material used in your injection molded products is compliant?

FirstMold places a high emphasis on environmental protection. All our raw materials and products comply with environmental standards. We can provide third-party test reports for the Acrylonitrile Butadiene Styrene raw materials we purchase, or we can buy materials from suppliers you specify and provide proof of raw material purchase. We are also prepared to collaborate with you on any reports or certifications needed for your products to pass various tests.

How do you handle non-conforming products?

If a product is non-conforming, FirstMold will immediately rework or scrap it and analyze the cause to prevent similar issues from recurring. We also provide clients with detailed reports and analyses of the non-conforming products to help them understand the issues. Additionally, FirstMold actively communicates with clients to seek solutions and ensure client satisfaction.

How do you control temperature in FirstMold's ABS injection molding services to prevent product deformation?

In the acrylonitrile butadiene styrene injection molding process, we prevent product deformation by precisely controlling mold temperature, injection speed, and injection pressure. We adjust these parameters based on the characteristics and requirements of the product to ensure accuracy and consistency. Additionally, we have a temperature control system that continuously monitors and controls the temperature of the mold and materials, ensuring accuracy and stability.

How can we optimize the ABS injection molding process to improve production efficiency?

Optimizing the ABS plastic molding process can be approached from several angles, such as increasing injection speed, reducing mold temperature, and optimizing barrel temperature. These measures can effectively improve production efficiency while ensuring product quality. Additionally, further efficiency gains can be achieved by improving mold design and optimizing raw material formulations. The key is to enhance production efficiency without sacrificing product quality, including appearance and performance.

What color issues might occur in ABS injection molded products? How can they be resolved?

ABS plastic molding might exhibit some molding defects, such as color variation. First, we recommend that clients choose standard colors or conduct color tests before production to ensure color consistency of the products. Then, we improve and optimize the mold design and injection molding process based on the experience of our engineers to ensure your products fully meet delivery standards.

What costs are included in the quotation for ABS injection molding?

The quotation for ABS parts production usually includes the following injection molding costs:

1. Material costs: This includes the purchase and transportation costs of ABS materials.

2. Processing costs: This includes the production and maintenance costs of injection molds, as well as the energy, labor, and equipment depreciation costs required for the injection molding process.

3. Packaging costs: This includes the costs of packaging materials, such as plastic bags, foam, etc., as well as the labor costs for packaging.

4. Tax and fee costs: This includes potential costs such as tariffs, tax, and freight charges, as well as other government taxes and transportation expenses.

In addition to these, the injection molding quotation may also include other costs, such as design fees, mold modification fees, testing fees for new molds, quality inspection fees, and after-sales service fees. The specific costs may vary depending on the manufacturer, region, and complexity of the product. When determining the injection molding quotation, it is advisable to communicate in detail with the specific manufacturer or supplier to understand the specific cost structure and pricing strategy.

What are your quality control standards for ABS products?

First, we use internationally accepted measurement standards to measure and inspect the dimensional accuracy and surface quality. This means we precisely measure all critical dimensions of the product to ensure they meet our design and customer requirements.

Secondly, we inspect the surface quality of the product to ensure there are no obvious defects or flaws. This includes checking whether the surface is smooth and free from scratches, dents, or other signs of imperfection.

Additionally, we test the material properties of the product. We check the hardness and toughness of the ABS material to ensure they meet our requirements and do not negatively affect the performance of the product.

Finally, we conduct additional tests to assess the durability and stability of the product. This includes long-term usability tests of the product under various environmental conditions to evaluate whether they can withstand the expected loads and conditions.

If you would like to learn more, you can refer to the “Injection Molding Inspection Standards“.

Can you use CNC machining of ABS as a substitute for injection molding processes?

We offer ABS plastic fabrication services, and we can use CNC machining of ABS materials to replace some injection molding processes. ABS has excellent physical, mechanical, and processing properties, making it suitable for substituting some injection molding processes. However, due to the characteristics of ABS material, 数控加工 cannot completely replace injection molding, especially in cases where large-scale mass production is required and precision demands are not high. Therefore, when considering using CNC machining as a substitute for injection molding, it is important to consider the specific application and requirements, and consult our professionals.

Can products made from ABS injection molding be surface treated?

Products made from injection molding can indeed undergo surface treatment. Common surface treatment methods include silk printing, painting, electroplating, anodizing, surface hardening, etc., to enhance the appearance and wear resistance of the products. The specific treatment method depends on the product’s application scenario and requirements. Before surface treatment, it may be necessary to clean the ABS products to ensure that the surface is free from impurities. The treated products should meet relevant quality standards and requirements to ensure their performance and service life.