CNC Turning Service

CNC Turning for Optimal Performance and Durability

- Perfect for Long, Cylindrical, and Threaded Components

- Unmatched Precision for Rotational Parts

- Ensures Superior Finish and Symmetry

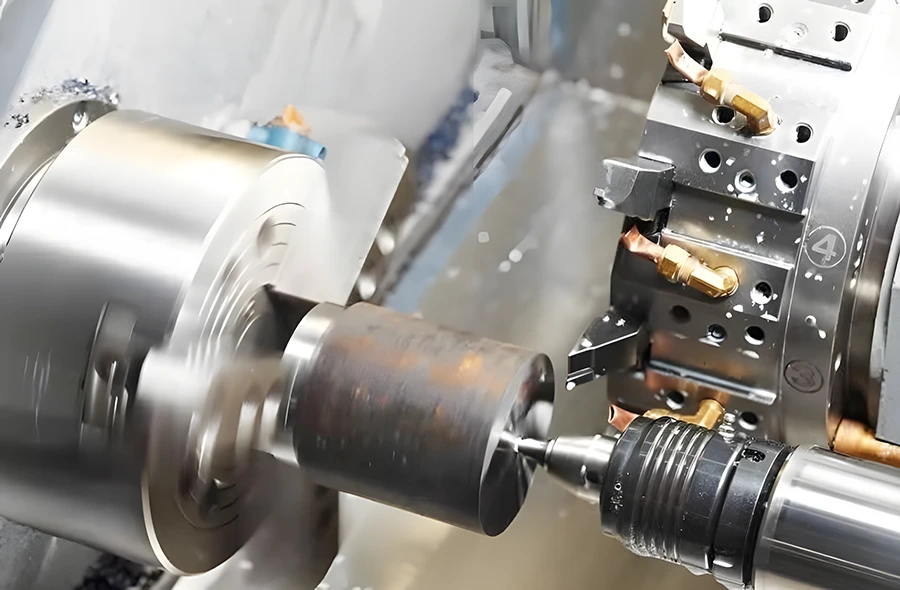

Reliable CNC Turning Services for High-Quality Parts

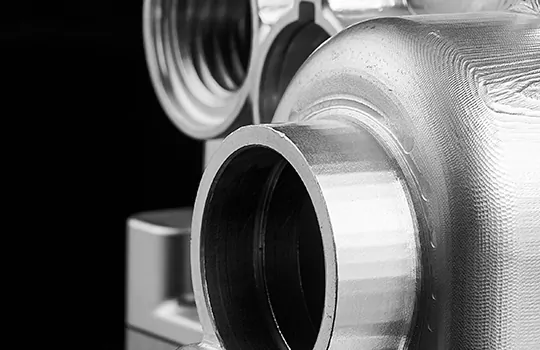

At Firstmold, we offer precision CNC Turning Services designed to deliver high-quality custom parts with quick turnaround times. Using advanced CNC turning equipment and skilled technicians, we produce parts with tight tolerances and complex geometries. Our CNC Turning Service is ideal for producing components such as shafts, bushings, couplings, and threaded parts, with materials including aluminum, brass, steel, and more.

Choose Firstmold for your CNC Turning Service needs and benefit from our commitment to quality, reliability, and precision craftsmanship.

- 24/7 Turning Service

- Diversified custom processing

Affordable Pricing

Experienced Engineers

Firstmold CNC Turning Capabilities

-

Expertise in DFM

-

Advanced equipment

-

Competitive pricing

-

Post-processing

At Firstmold, we have extensive experience in DFM, which enables us to optimize the design of your parts for manufacturability. Our team of engineers works closely with you to identify any potential issues with your design, and suggest modifications to ensure that your parts can be produced efficiently and cost-effectively using our CNC turning service.

We use the latest and most advanced CNC turning machines and equipment to ensure that our clients receive the best possible results.

We offer competitive pricing for our CNC turning services, without compromising on quality. We also work with our clients to find cost-effective solutions for their projects.

We provide a range of post-processing and finishing services to ensure that your parts meet your exact specifications and are ready for use in your final product. With our commitment to quality and attention to detail, you can trust us to deliver exceptional CNC turning services that meet your needs and exceed your expectations.

What can you experience with our turn-mill machining?

Short Process Chain & High Production Effenciency

Turn/Mill can complete all or most of the machining processes in one setup, greatly shortening the product manufacturing process chain. This can guarantee your product delivery time.

Reduce Clamping Times & Tight Tolerance

The reduction of the number of loading cards avoids the accumulation of errors due to the transformation of positioning reference. The online inspection ability can control the accuracy of key parameters in the machining process, improving the machining accuracy.

Turning and Milling Available & Complex Parts Machining

Ordering Process

Upload Your Design File

Submit your design file to initiate the process.

Choose Materials & Techniques

Select the materials for your product.

Instant Quotation & Ordering

Get a quote instantly and submit your order.

Precision Turning Taken Care

Leave the production to our capable hands.

Receive Your Item On Time

Get your finished item delivered to you.

We are trusted by many clients

We offer turning services for various industries including automotive, aviation, electronics, and medical devices. Our products are exported to multiple countries including the USA, Canada, UK, France, Australia, Singapore, and Malaysia. We have established partnerships with renowned companies such as Tesla, Honda, Porsche, and more.

Our Design Tips for Your Turned Parts

01

Avoid Long and Slender Parts

02

Simplify Complex Geometries

03

Incorporate Chamfers and Fillets

04

Select Machinable Materials

05

Maintain Consistent Wall Thickness

06

Ensure Adequate Clamping Surfaces

Please note that even if you don't follow these design tips, we can still manufacture your parts perfectly. However, to help you reduce unnecessary costs, we recommend designing your parts according to our guidelines.

CNC turning is a manufacturing process where a rotating workpiece is cut by a cutting tool to remove excess material and create the desired shape. It is a type of CNC machining that is used to produce cylindrical parts with a high degree of accuracy and precision. The process is automated using computer numerical control (CNC) programming to control the movements of the cutting tool and the workpiece. CNC turning can be used to produce a wide range of parts in various materials, including metals, plastics, and composites.

CNC turning can work with a wide range of materials, including metals like aluminum, brass, steel, stainless steel, and titanium, as well as plastics like ABS, acrylic, nylon, and polycarbonate.

CNC Turning offers several advantages, including high precision, consistent quality, and fast turnaround times. It also allows for complex shapes and features to be produced efficiently and accurately.

At Firstmold, we understand that lead time is critical for our customers’ success. Our state-of-the-art CNC turning equipment and experienced team allow us to produce parts quickly and efficiently without sacrificing quality. The lead time for CNC turning parts typically depends on factors such as the complexity of the design, the quantity of parts needed, and the materials used. However, we always strive to meet our customers’ timelines and offer rush services for urgent orders.

CNC milling involves cutting material using a rotating cutting tool, while CNC turning involves rotating a material and cutting it using a stationary cutting tool.

FAQs For CNC Milling Services