数控铣床服务

Shape your vision, fast! Create anything you desire.

- Mature tech support and quote system

- Precision equipment, quality staff, guaranteed delivery

- Problem-eliminating engineering and quality-ensuring testing

- Custom processing, efficient and responsive customer support

Providing good alternative options for rapid prototypes.

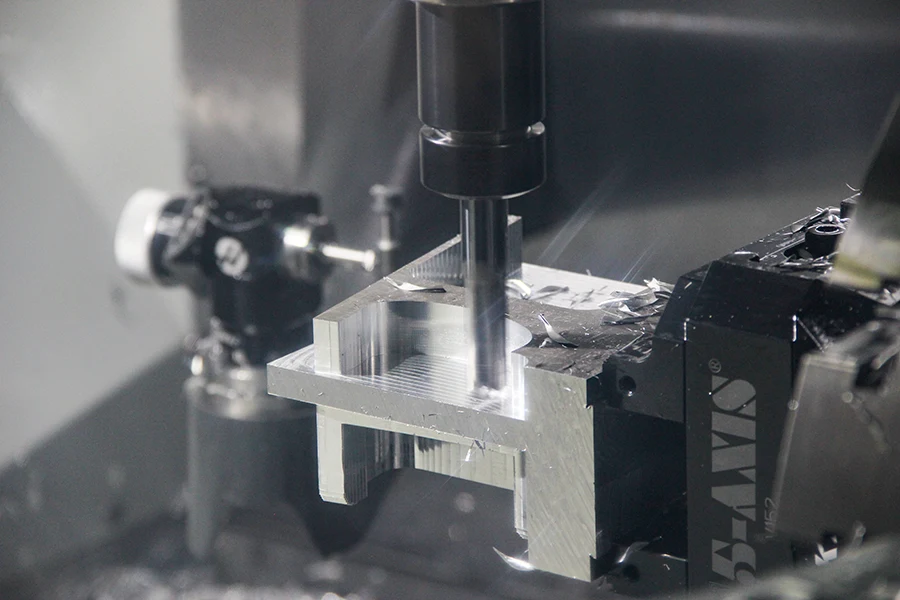

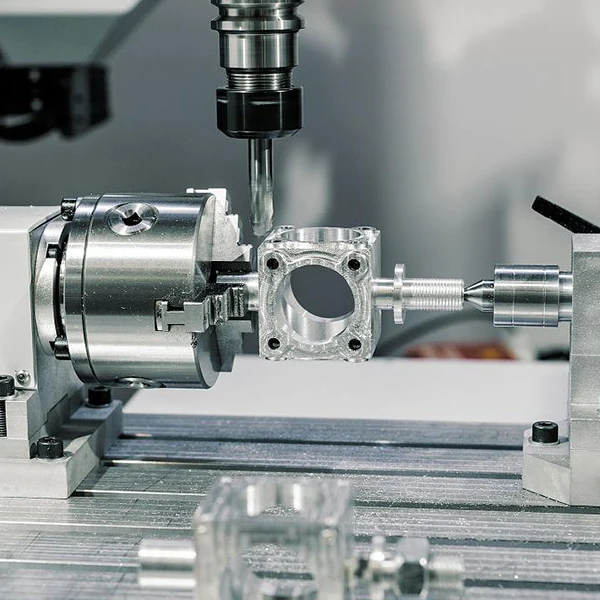

Our 40+ milling machines, including 3 axis, 4 axis, and 5-axis CNC milling centers, are capable of producing rapid prototypes and low-volume units of precision parts with high functionality and complex geometries. CNC milling is ideal for creating parts with flat and jagged geometries like slots and grooves, as well as for post-machining to add details to turned, 3D-printed or molded parts.

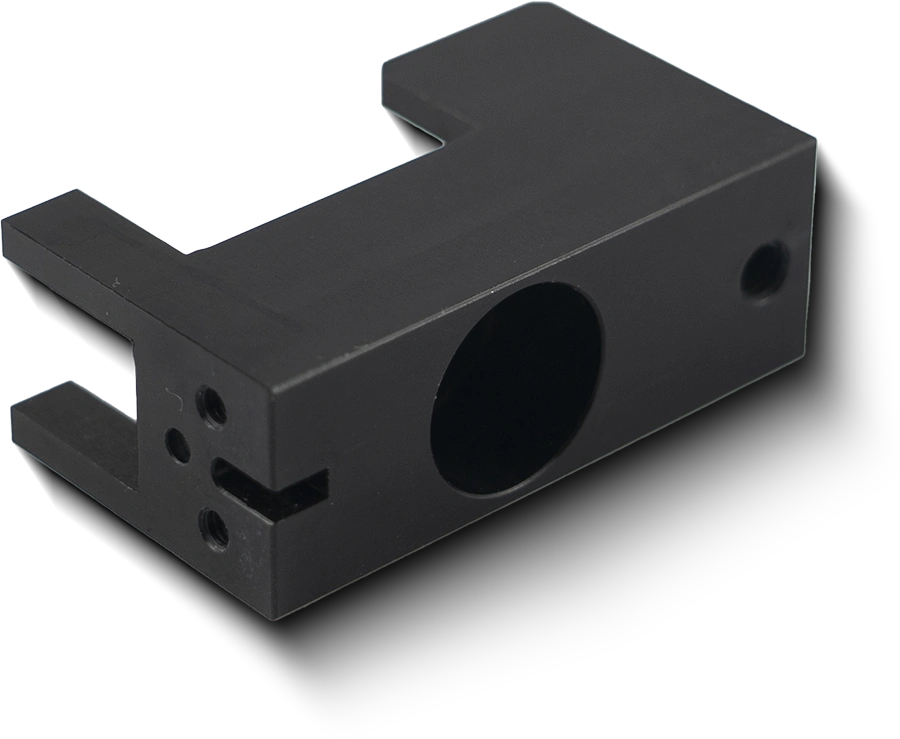

We specialize in making functional parts like brackets, gears, fittings, enclosures, housings, mold tooling, engine parts, medical instruments, punches, and dies, making it an ideal fit for use across many industries.

Tight Tolerance

Creative Design

Mass Processing Available

Industries We Can Mill For

Craft Precision with a Click

Our Advantages and Benefits in Milling

Precision

Our 3-axis, 4-axis, and 5-axis CNC milling centers ensure precision and accuracy to within ±0.001″. This is critical in industries such as aerospace, medical, and automotive where precision is paramount.

Speed

With our 40+ milling machines and skilled machinists, we can produce parts quickly and efficiently without sacrificing quality.

Complex Geometries

Our CNC milling service is ideal for producing complex parts with intricate geometries, such as slots, grooves, and other custom features.

Material Diversity

We can mill a variety of materials including metals, plastics, and composites to fit your specific needs.

设计灵活性

Our experienced engineers and machinists can provide design input to help optimize your parts for production, and can even produce low-volume custom parts with short lead times.

经济高效

With our streamlined process and advanced machinery, we can provide cost-effective milling solutions without sacrificing quality or accuracy.

Our Milling Capability

Mills

40

Department Headcount

60

Monthly Production

100,000 units

Tolerance Standard

ISO-2768-M (for both metal and plastic)

Maximum Tolerance

±0.0254mm (±0.001″)

Maximum Milling Width

800mm (31.50″)

Maximum Machining Height

800mm (31.50″)

Maximum Machining Depth

200mm (7.87″)

Minimum Machining Dimension

5mm x 5mm x 5mm (0.2″ x 0.2″ x 0.2″)

Maximum Machining Depth

200mm (7.87″)

Fastest Delivery Time

3-7 Days

We are trusted by many clients

Ordering Process

Upload Your Design File

Submit your design file to initiate the process.

Choose Materials & Techniques

Select the materials for your product.

Instant Quotation & Ordering

Get a quote instantly and submit your order.

Precision Milling Taken Care

Leave the production to our capable hands.

Receive Your Item On Time

Get your finished item delivered to you.

Supported Milling Materials

FAQs For CNC Milling Services

CNC milling is a manufacturing process that involves using computer-controlled machines to remove material from a workpiece to create a desired shape or design. The milling machine uses rotating cutting tools to remove material from the workpiece to achieve the desired shape. This process is used to create a wide range of parts and products with high accuracy and precision.

CNC Milling can work with a wide range of materials including metals (such as aluminum, brass, stainless steel, titanium, and more), plastics (such as ABS, acrylic, nylon, polycarbonate, and more), and even composites (such as carbon fiber and fiberglass). Some materials may be more challenging to work with than others, and may require specialized tooling or techniques to achieve the desired results.

CNC milling provides more precise and consistent results than manual machining, and it allows for more complex geometries and features to be created.

The typical lead time for CNC milling parts at Firstmold varies depending on factors such as the complexity of the part, the quantity needed, and the availability of materials. However, we always strive to provide our customers with fast turnaround times and efficient production processes. Contact us to discuss your specific project and lead time requirements.

Yes, we offer both CNC milling and CNC turning services at Firstmold. Our state-of-the-art facilities include a wide range of CNC machines, including milling and turning centers, which allow us to produce high-quality parts with a quick turnaround time. Our experienced team of engineers and machinists can help you determine which service is best suited for your specific needs and requirements. Contact us today to discuss your project and learn more about our CNC milling and turning services.

Yes, CNC milling can be more cost-effective and time-efficient than other manufacturing methods, especially for larger production runs or complex parts.

Yes, CNC milling is an ideal solution for creating rapid prototypes and small production runs of custom parts. It allows for quick and accurate adjustments to be made, resulting in faster product development and time to market.