What's Sandblasting?

Advantages of Sandblasting for Your Product

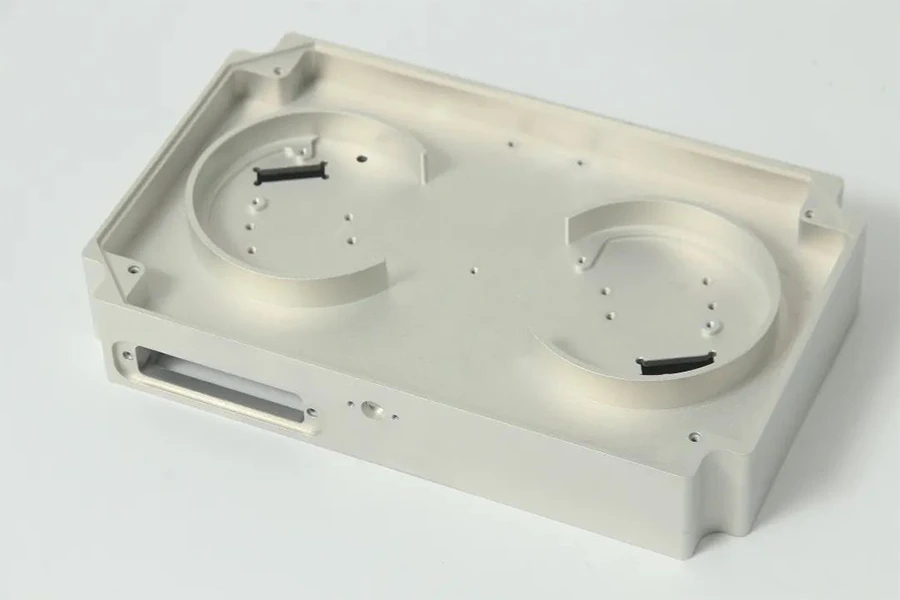

Improving the Performance of Mechanical Parts

Mechanical parts can achieve a smoother finish and have micro-pits on the surface that store lubricating oil, improving lubrication conditions, extending part lifespan, and reducing noise. Examples include gears, crankshafts, textile machinery, and sewing machinery.

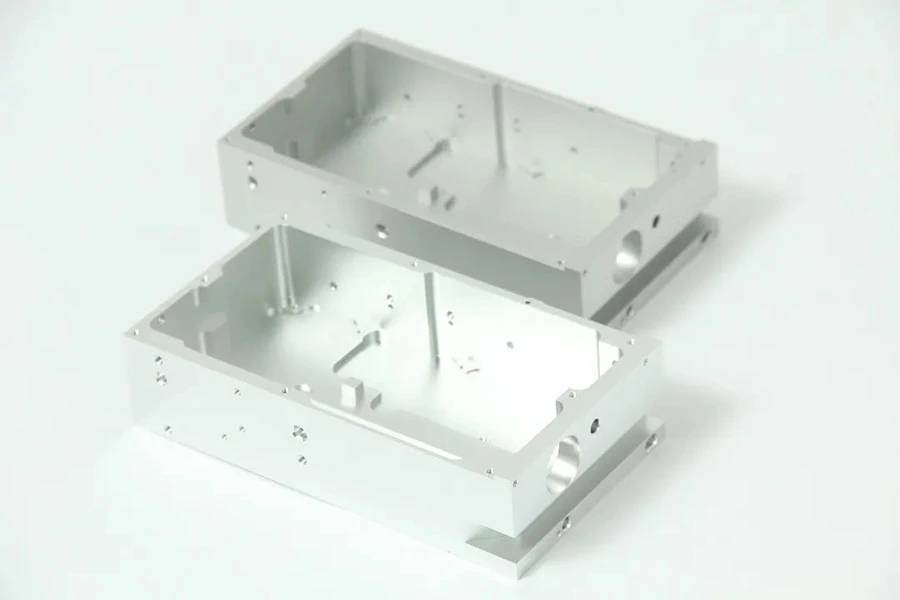

Preparing for Other Surface Treatments

Sandblasting before electroplating increases the bond strength of the plating, especially for hard chrome plating. It also enhances the adhesion of paint and coatings and improves bonding quality for adhesive parts.

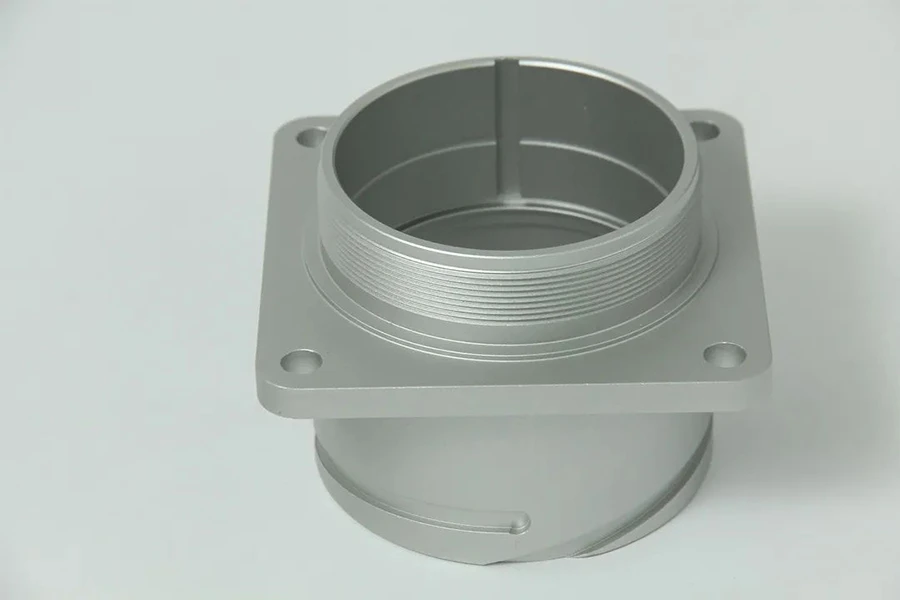

Removing Oxide Scale

Sandblasting effectively removes oxide scale, residual salts, and stains from metal parts after heat treatment, improving surface finish, especially for complex molds and precision parts.

Removing Dirt and Rust

Sandblasting effectively cleans molds used in forging, stamping, rubber, tire, plastic, and glass production by removing mold release agents and scorch marks, thereby extending mold life.

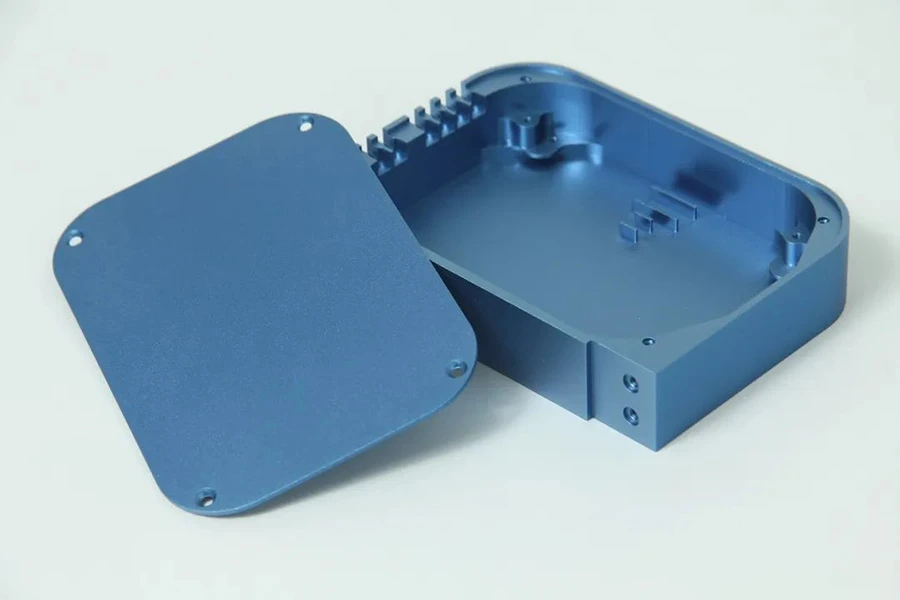

Surface Decoration

Sandblasting is used for parts that need to be smooth but non-reflective, such as surgical instruments. It is also used for frosted glassware, instrument panels, plastic drawing paper, and special fabrics.

研磨

Sandblasting is highly effective for polishing, especially for complex shapes like impeller blades and various mold surfaces. It is an economical method for polishing ceramics, diamonds, and jewelry.