3D Printing Service

Transforms ideas into tangible prototypes quickly and affordably with 3D printing service

- Rapid turnaround times

- Enables concurrent manufacturing of multiple parts

- Accessible technology for startups and small businesses

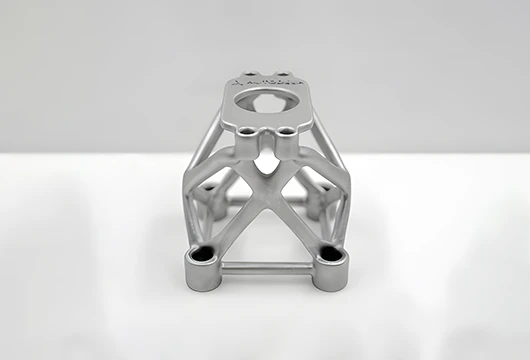

Beautifully Designed CNC Milled Parts for Any Industry

Equipped with multiple large-scale industrial-grade SLA photopolymerization 3D printers, one large-scale industrial-grade SLS laser sintering 3D printer, as well as high-precision metal 3D printers and HP imported MJF inkjet 3D printers, the 3D printing workshop covers an area of 1000 square meters.

Although our 3D printing scale is not large, it is sufficient to meet your various needs through our rapid prototyping solution, which combines 3D printing, CNC prototyping, and vacuum casting. At FirstMold, you will have more options, whether in terms of delivery time or cost.

Main 3D Printing Services At Firstmold

Equipped with various 3D printing process capabilities.

3D print your creativity

Why Choose Us For 3D Printing

Instant Quote

Upload your 3D files to our digital quoting platform to receive instant pricing and manufacturability feedback.

质量保证

We have obtained ISO9001, ISO14001, IATF16949, and ISO27001 international certifications for several consecutive years. The establishment and application of a 6S management system provide a strong guarantee for your product quality.

Order Online Tracking and Management

Through our self-developed ERP and CMS systems, we have a perfect management mechanism to achieve refined production. You can view the project progress in real-time, making everything traceable and safeguarding your project.

3D printing surface treatment

3D printing surface treatment refers to the process of forming a layer on the surface of 3D printed products that has different mechanical, physical, and chemical properties. The main purpose of 3D printing surface treatment is to meet the requirements of the product’s corrosion resistance, wear resistance, decoration, or other special functions.

Common 3D printing surface treatment methods include sanding, polishing, sandblasting, painting, etc.

FAQs For CNC Machining Services

We have a very detailed article on CNC Machining, click on the link “What is CNC Machining“.

CNC machining can work with a wide range of materials, including metals such as aluminum, brass, copper, stainless steel, titanium, and more. It can also process various plastics, such as ABS, PEEK, POM, nylon, polycarbonate, and others, as well as composites, wood, and even some types of ceramics. The specific materials that can be used with CNC machining will depend on the capabilities of the machine and the specific requirements of the project.

CNC machining offers a high level of precision and accuracy in producing parts, which can be difficult to achieve with other manufacturing methods. It also allows for flexibility in design changes, quick turnaround times, and the ability to work with a wide range of materials. Additionally, CNC machining can often be more cost-effective for producing small to medium-sized runs of parts.

At Firstmold, the typical lead time for CNC machined parts depends on the complexity of the part and the quantity ordered. Generally, we can produce CNC machined parts within 3-10 business days, but more complex or larger volume orders may require longer lead times. We work closely with our clients to ensure that we provide accurate lead times based on their specific needs and requirements.