Mass Production Service

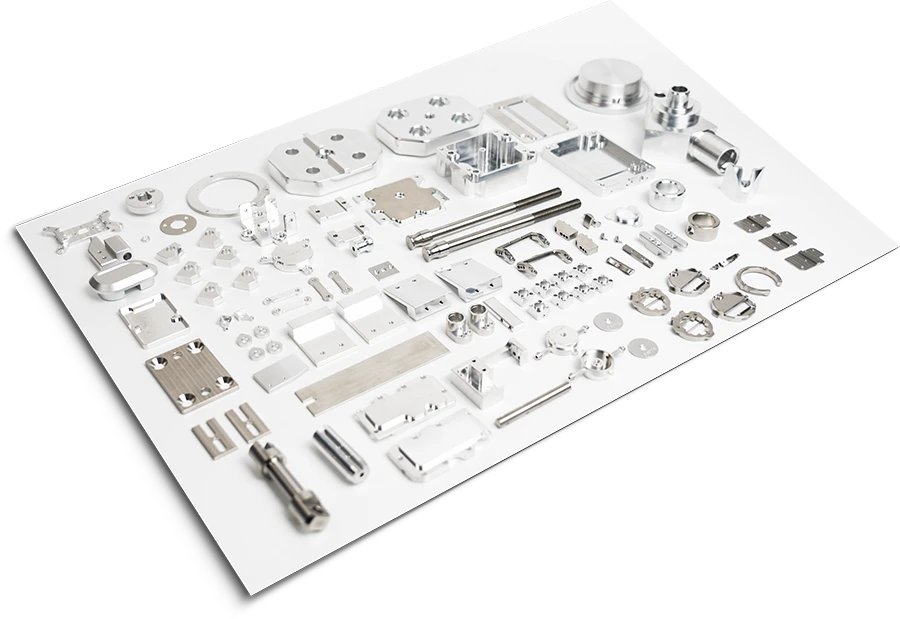

Focusing on mass production of plastic & metal products, providing one-stop solutions

- Full production output of up to 2 million pieces per month

- Stable and consistent productivity

- Strictly control the scrap rate within 0.5%

Save your money with mass production services

Firstmold’s mass production refers to the mass production of plastic products or parts by molding process and metal components by die casting service and CNC machinnig service. Rather than low-volume manufacturing, mass production integrates all of our capabilities to provide a one-stop shop for your product or idea, manufacturing parts, components and products to make your business more prosperous!

Our Productivity In different Industry

- Automotive interior and exterior parts production on a large scale

- Aerospace part high-volume fabrication

- Consumer electronics component extensive assembly

- Medical device part large-scale manufacturing

- Home appliance component bulk production

- Industrial machinery part widespread fabrication

- Energy sector component extensive production

- Precision instrument and timepiece component large-quantity production

- Telecommunications part mass production

- Agricultural machinery component high-volume manufacturing

- Automation system and robotics part extensive making

- Lighting and electrical component mass production

- Plumbing and HVAC system part mass fabrication

- Personal care product component volume fabrication

- Optical and photographic gear part mass fabrication

Craft Perfection with a Click

Mass production with extreme attention to quality control

Details of quality control requirements in mass production

Different factories or customers have different requirements for inspection products. Firstmold has our own quality control standard, and if the customer does not have a special request, we will execute it according to our own standards. The content to be inspected will include size, function, appearance, and other aspects.

- 外观

- Dimensions

- Performance

No defects

No defects are allowed on the product surface, including flash, flow lines, sink marks, short shots, etc.

Surface finishing

The quality of the surface finish of the product, including factors such as roughness, and uniformity. They can affect its appearance, durability, and overall quality

Functionality Testing

Testing the product to ensure that it performs its intended functions as specified, such as electrical or mechanical testing.

壁厚

Dimensional Accuracy

Make sure the degree to which the product conforms to its specified dimensions, such as length, width, height, and diameter.

Environmental Testing

Testing the product under various environmental conditions, such as temperature, humidity, and vibration, to ensure that it will perform as expected in its intended environment.