Low-volume Production Service

Small Batch, Big Impact: Experience Quality Low-Volume Production

- Flexibility and responsiveness to meet your specific needs

- Increase your profitability & lowering production costs

- High-quality production of unique or custom products

Risk-Free Low-Volume Manufacturing for All Your Needs

Bringing a new product into the market or bringing an old one into a newer market? Low-volume manufacturing is quick and affordable solution geared at mitigating product development risks associated with introducing new products to new markets.

Unlike the high risk and high capital requirement associated with high-volume production that can run into hundreds of thousands or even million units, low-volume manufacturing is a popular philosophy in general manufacturing that has helped several new products navigate the risky journey of idea to product quickly and affordably without compromising on quality standards.

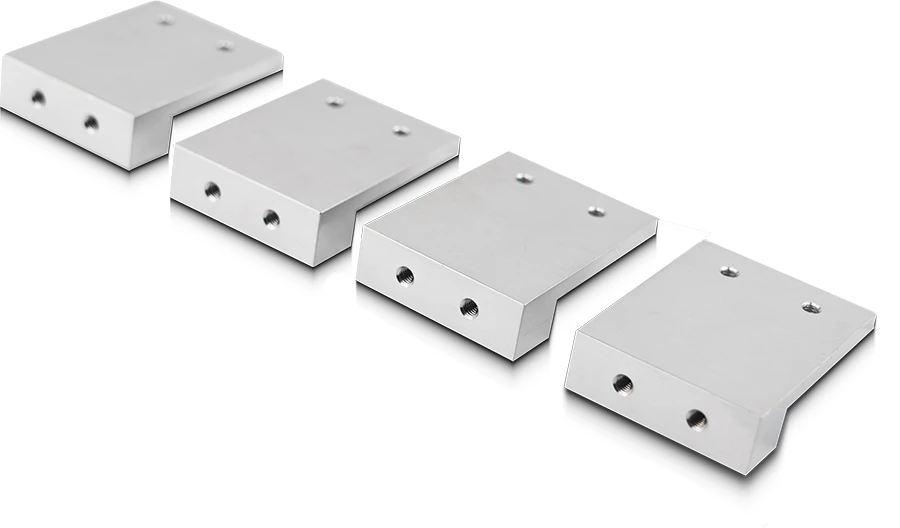

At Firstmold, we achieve low-volume manufacturing with any one or a combination of two of four technologies namely CNC machining, Additive Manufacturing (3D Printing), Rapid Tooling and Polyurethane Vacuum Casting. Firstmold has no minimum order requirements, and can deliver anything between 1 to 1000 units in as quick as 1 to 7 days, and can make low-volume parts that are accurate to 0.005” in dimensions and tolerances.

- 注塑成型

- 数控加工

- 压铸

- Wire EDM

- Vacuum Casting

- 快速原型制作

Enhanced Quality Assurance for Low Volume Production

At FirstMold, it is quality over high-volume runs that we are committed to, ensuring that even small-batch orders are held to rigorous standards. It does not mean that low-volume production compromises quality. Each of our projects is dealt with its detailed and diligent examination procedures. The non-destructive and modern tools that we embrace include a coordinate measuring machine and some other non-destructive testing techniques that result in great accuracy in every part that is fabricated by our firm. Whether the company is producing 10 units or a thousand, the quality control department will ensure that each piece is as near to the designed pattern as possible to reduce the number of faulty items that may be produced and in turn increase customer satisfaction.

Custom Solutions for Niche Markets

One major benefit is being able to cater to niche markets with customized solutions. We offer production strategies tailored to your needs because various industries have different requirements. Our engineers will work with you to develop custom tooling and production processes to maximize your efficiency while keeping costs at a minimum. This allows for flexibility in supporting a wide variety of industries, such as but not limited to the automotive, aerospace, medical, and consumer electronics industries—guaranteeing your product answers market demands without overstretched budgets.

- 注塑成型

- 数控加工

- 压铸

- Wire EDM

- Vacuum Casting

- 快速原型制作

Small Batch, Big Impact with a Click

我们为您的制造业带来的优势和好处

Customization options

Our low-volume production service is highly customizable, allowing customers to choose from a variety of materials, finishes, and design options.

Quality assurance

We utilize advanced quality control measures to ensure that every part we produce meets the highest standards of quality and consistency.

Cost-effective

Customer support

Faster time-to-market

Flexibility

Small Batch Production Ordering Process

1. Upload Project Designs

Upload your project design and tell us all the important details

2. Quotation Reply and Disgn Advices

We will give you a quote and some advice on product design within 24 hours

3.Create BOM and Raw Material Preparation

The PMC department issues the production plan, while the purchasing department prepares the raw materials

4.Production Arrangement and Quality Control

Schedule production according to the production plan and make the quality control

Quality in Every Quantity

Metals

- 不锈钢

- 铝质

- Alloy Steel

- Soft Steel

- 黄铜

- 铜

- 钛

- Inconel

Others

- Rubbers/Elastomers

- Customer-supplied materials

Low-Volume Production Materials

Low-volume manufacturing can be executed with just about every material suitable for mass manufacturing. At Firstmold, our low-volume production services are compatible with materials in the plastic, metal and elastomer categories. We understand the importance of material compatibility, which is why we stock materials that will help our clients deliver on the quality, functionality, strength and any other specifications for their product.

Low-Volume Production Finishes

- 标准

- Brushing

- Polishing

- High Gross Polishing

- Bead Blasting

- Painting

- Tinting

- 阳极氧化

- Soft-touch Painting

- Crome coating & Metal Platingh

- Logo & Symbols

- Powder Coating

FAQs For Low Volume Production Services

Low-volume production refers to the manufacturing of a relatively small number of parts or products. This production method is often used for testing purposes, small-scale production, or to bridge the gap between the prototype stage and full-scale production. Low-volume production typically involves the use of specialized equipment and processes that are designed to produce a smaller number of parts at a lower cost than traditional mass production methods.

Low-volume production is a good option when you need a small quantity of parts or products, typically less than 10,000 units, but don’t want to invest in the high upfront costs of traditional mass production methods such as injection molding or die casting. It’s also a good option for prototyping, testing, or when you need to quickly produce parts or products for market testing or early stage production. Low-volume production allows for flexibility and customization without the high tooling costs associated with mass production methods.

The benefits of low-volume production include lower upfront costs, faster turnaround times, greater flexibility for customization, and reduced waste. Low-volume production can also provide an opportunity to test and refine your design before investing in mass production, potentially saving time and money in the long run. Additionally, low-volume production can allow for greater agility in response to market demand and changes in product design.

Low-volume production can benefit a wide range of industries including automotive, aerospace, medical, consumer electronics, and more. It’s particularly useful for industries that require customized or specialized parts and products, or for those that require a fast turnaround time for prototyping or early-stage production. Low-volume production can also be beneficial for startups or small businesses that require a smaller quantity of parts or products to launch their business or test their product in the market.

The materials used in low-volume production can vary depending on the specific application and industry, but typically include plastics, metals, and elastomers. Common materials include ABS, polycarbonate, nylon, aluminum, stainless steel, and silicone rubber. The choice of material depends on the requirements of the part or product, including strength, durability, flexibility, and temperature resistance.

Yes, low-volume production can be an excellent option for prototyping, especially for parts that will eventually be manufactured using low-volume production methods. By using low-volume production for prototyping, clients can test their product and make design iterations before committing to larger production runs.

The minimum order quantity for low-volume production can vary depending on the manufacturing process and material being used. At Firstmold, we offer low-volume production services with no minimum order quantity, allowing our clients to produce the exact number of parts they need without any excess waste or cost.