Family Molding Service

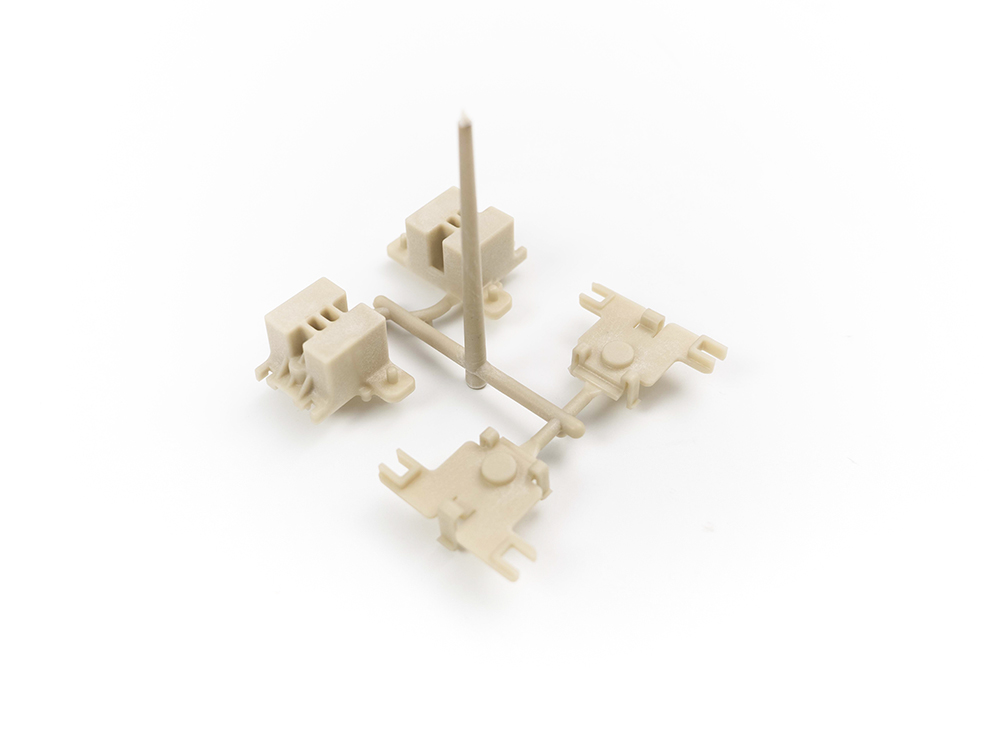

Family molding, where different parts are produced simultaneously with one set of molds.

Custom Family Injection Molding Solutions

We offer all our clients the options of low-cost one-stop-shop family molding solutions. While our family molds using the same colors, our post-processing solutions can finish individual components of your parts in a different array of ways. We are very relationship-focused. This is why many of our solutions can be customized to meet your project requirements.

我们为您的制造业带来的优势和好处

Shorter leadtimes to gain market edge

Got tight deadlines? Looking to beat the competition? Our in-house capacity and network of vetted manufacturing suppliers is all you need to get your part into production in no-time.

Unbeatable Design Support

Our design team consists of experts that will help bring the best value out of your project. From our practical design-for-manufacturing evaluation to our immense attention to detail, you can be assured of making beautiful, functional designs every time you work with us. We open your project to different design possibilities and complex geometric configurations, all made feasible with CNC machining and precision injection molding

Tight Tolerances

At Firstmold, we are capable of using optimized processes to make family mold tooling and components with high precision and tolerances of up to 0.010”. Should tighter tolerances be required, we shall evaluate the feasibility, while leadtimes and production costs will increase.

Zero MOQs

At Firstmold, we work with every client irrespective of their volume needs. Our family injection molding solutions are open to everyone. Need low-volume parts? choose our Rapid Aluminum Tooling option. We have zero minimum order quantities to meet the budget or production requirements of all our clients.

Lower Production and Tooling Cost

Our Family Injection molds are an efficient method of making functional parts with multiple components. With these family molds, multiple components of the same part can all be made in one tool and one injection molding, saving thousands of dollars on making individual tooling and molding cycles.

One-stop-shop Services

Firstmold is with you from start to finish. Our complete suite of services mean that we will be with you from design validation to insert molding, post-processing and other finishing services. We simply don’t stop until your end product emerges exactly how you envisioned it.

Seamless Ordering

Firstmold family injection molding makes your part ordering and inventory easier to manage and track. With one order, full sets of parts can be made without worrying about raising orders for individual components in your part.

查看客户评价

"当我们第一次要求进行数控加工时,我们尝试联系了 First Part,他们在几小时内就给出了价格、交货时间和针对我们要求的建议。他们的专业服务和高质量控制令我非常满意。我会毫不犹豫地向我的朋友推荐他们。

布朗-亚伯拉罕

杰孔褐(Jackon Brown

24 小时内免费快速 DFM 反馈

Family Injection Molding Manufacturing & Processing

Family injection molding is a delicate process that requires adherence to strict processing parameters to guarantee defect-free parts and components. We achieve the high level of consistency and quality by ensuring we process the mold tool to the tightest of tolerances. There are 3 criteria to be met for our family injection molding. First, the part must be of the same color and material. Next, parts must be ordered and in the same quantity as the molding of each component occurs simultaneously. Lastly, the parts must be almost equal in size and volume to one another to prevent short shots and underfills. At Firstmold, our design experts and engineers are adept at mold fill simulations, helping you mitigate the risks of defects. Our molding equipment has zero downtimes, running 24/7 to truncate delivery times and meet customer timeline expectations. We achieve mold tolerances up to +0.010 inches for parts that require the highest precision and dimensional accuracy, and offer a “Lifetime mold guarantee System” that stores and maintain our clients mold indefinitely for a small token of storage fee. This way, you can be rest assured that your molds will remain in the best shape over the cycle of production it was intended.

材料

Choose from simple commodity plastics to high-performance engineering-grade resins to deliver all the required properties in your plastic injection molding parts. We also stock frequently requested and popular resins in-house to bolster our supply chain for quick-fire projects. Below are some of the categories of materials we work with:

Stock materials – PP, PVC, PS, PE, HIPS, PET | ABS, PC, POM, Nylon/PA66, PBT

Stock materials are the most popular on-the-market material solutions that fit into the everyday needs of conventional molding. These materials are more readily available and affordable for use.

Custom materials

Explore custom materials made for special production or product-use cases. Our custom materials are well engineered to deliver enhanced performance.

Learn more about our molding materials

Finishes

We have the capability to process finished parts into any desired finish and texture in line with the SPI standards. Our finishing options strike a balanced mix between cosmetic and aesthetic applications. All our injection molded parts can be finished in 4 basic options. These include:

· Standard Finish

Usually SPI B-2 Standard. The standard finish will have your parts delivered as molded with no significant cosmetic inputs on interior facing and non-aesthetic sections of your part.

· Textured/Grained

Textured, grained or patterned surfaces ranging from matte to swirl, lines, mesh and more. Texturing may be done via mold texturing or via post-processing techniques.

· Regular Polished

Regular polishing to keep part surface smooth and uniform. High to low luster that delivers a clean, presentable appearance.

· Mirror Polished

High polish with exemplary amount of detail and reflectiveness in the surface of the part. Surface is bright and shiny with a look and feel that is premium.

· Other Finishing Capabilities

Save time, money and logistic efforts by completing your parts final touches with Firstmold. We provide a range of secondary processing options post-molding to decorate, brand and customize your part. Our secondary operations currently include:

· UV coating

· Silk or Pad printing

· Chrome plating

· Laser etching

· Labelling

· Engraving

· Threaded Inserts

· Media blasting

· Assembly

· Painting/Spray painting

· Learn more about our other finishing capabilities

工业

Firstmold serves a broad range of clients across a range of industries. Our manufacturing solutions are widely employed in the medical, consumer products, automotive, aerospace, Robotics & Automation and defense industries. We have over 20 years of experience in prototype development, product development and mass production during which we have evolved along with the industry-best practices, equipment and capabilities. Our pool of seasoned engineers are adept at optimizing design and executing production with high precision. We provide a superior advantage garnered through our understanding of the different context and nuances for product development across every industry.

汽车

Aerospace and Defense

医疗

Optimize efficiency, reduce weight and mitigate flight risks with our custom manufacturing materials for the aerospace industry.

Surgical-grade parts, wearables and bio-compatible components that meet FDA requirements to deliver life-saving solutions.

电子产品

Consumer Products

Robotics & Automation

Achieve tight tolerances and complex geometries in consumer electronic products to cater to the various style and class of your end-users.

Create exquisite design that is affordable and scalable to cater to the ever-changing consumer product trends.

Eliminate downtimes and boost efficiency with on-demand components that keep production running while integrating with existing lines and complimentary technology.

Additional Resources & FAQs

1. What is Family injection molding?

Family injection molding is a molding technique that creates multiple components of the same family of parts in a single injection molding cycle.

2. How does it work?

Family molding works the same way as injection molding, however, instead of designing the mold to house one part, family molds contain multiple cavities for different individual components that make up the part.

3. Why should I use Family injection molding?

There are many benefits of using family molding. Some of the most common advantages include consistency, higher cost efficiency, quicker leadtimes and easier ordering.

4. When should I choose Family injection molding?

Choose family injection molding when multiple components of your parts are going to be made from the same materials of thermoplastics, same color and same order volumes.