Grinding for engineers isn’t just about making things smoother—it’s about making them better. From the sleek finish on a smartphone to the precise fit of a car engine component, grinding is the hero behind countless products. This meticulous process plays a vital role in ensuring that products meet the highest standards of quality, finish, and precision. Grinding involves removing material from a workpiece using abrasive tools to create smooth and precisely shaped surfaces that meet particular specifications.

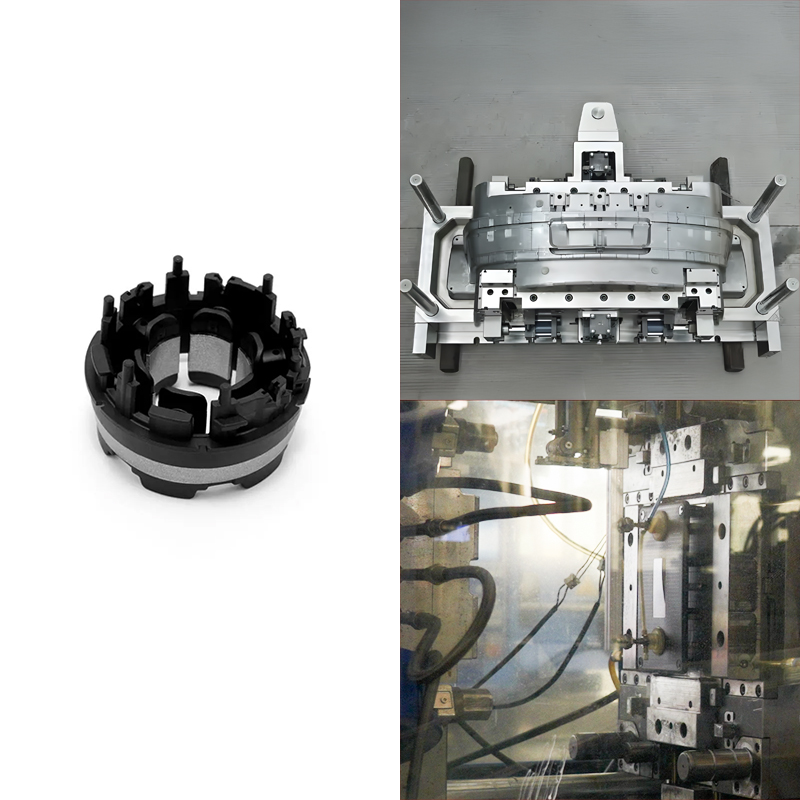

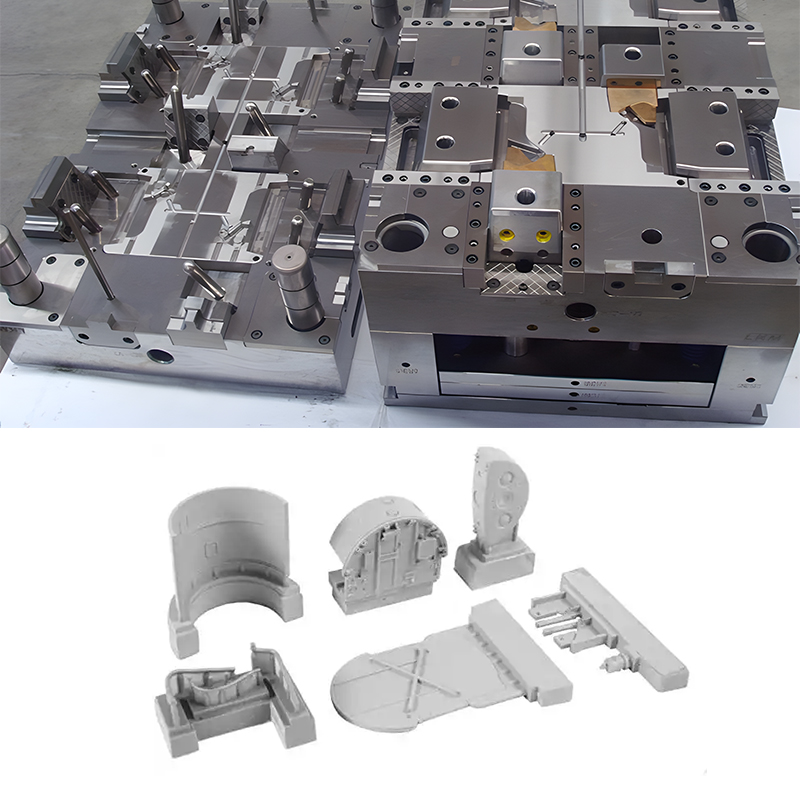

In the dynamic world of engineering, grinding is more than a finishing touch. It’s a vital step in the production process that must meet the requirements. It is highly beneficial in the injection molding industry to yield parts with great surfaces. Many industries, such as the automotive and tooling industries, depend on achieving tight tolerances and excellent surface finishes.

In this article, we’ll explore the grinding principles, the types of grinding processes, their application, and their overall significance in transforming raw materials into precision products. By the end, you will have a solid knowledge of the factors that make grinding important in contemporary engineering. Therefore, it will help to make better, more reliable components.

What is Grinding?

Grinding is a machining process that involves an abrasive material to help remove tiny pieces of material from a workpiece’s surface. It’s like giving your workpiece a meticulous trim. The objective is to achieve a specific dimension, shape, or finish that meets precise engineering specifications.

Unlike other machining processes, such as turning or milling, grinding can be up to ten times better in surface finish and precision. Modern grinding machines have continued to evolve with the advancement of technologies like automated CNC systems, which are extremely accurate.

A Historical Overview

Grinding technology has evolved significantly over the years. In the 19th century, it involved a manual process where simple rudimentary tools and stones were used to grind and shape objects. Achieving the desired results required a lot of hand operation and considerable skill. As a result, the process was labor-intensive. These machines involved a rotating stone that sharpened and shaped metals. Later, with the introduction of power-driven machines, a more mechanized process came along that adapted more sophisticated machinery.

Working Principle Of Grinding Machines

At its core, grinding involves an abrasive wheel or belt that typically rotates as it’s brought into controlled contact with a work surface. Most abrasive wheels are made of aluminum oxide or diamond. This grinding wheel has some abrasive grains held together in a binder. These abrasive grains act like tiny cutting tools, shearing away small chips of material from the workpiece. During the process, the tool’s grinding surface comes into contact with the workpiece. When the movement is relative to each other under pressure, the sharp edges on the tool produce the cutting action (Plastic deformation). Some of these particles might roll or slide in between these surfaces and result in slippage (elastic deformation).

Although these particles produce a small amount of cutting action, they evenly remove a thin layer of metal from its surface. Similarly, due to grinding pressure, the workpiece gradually achieves high dimensional accuracy with low surface roughness. This occurs due to the passivated abrasive particles squeezing the peak points of the processed surface.

When using abrasives like steric acid and chromium oxide, a chemical reaction might occur. A thin film of oxide forms on the processed surface. However, it wears off easily during the grinding process. The oxide coating is continuously created and removed throughout the grinding process, smoothing up the treated surface through numerous cycles of repetition.

Due to friction, these abrasive grains are subjected to frequent wear, and the amount removed from the material is reduced. The abrasive granules are removed from the surface through a dressing procedure to restore the wheel’s ability to cut properly. Then, the bonding substance is vitrified to strengthen and harden it, and the wheel is reconditioned.

Материалы

Grinding typically involves several materials, especially those that are hard or require a fine finish. Such materials include metals like steel, aluminum, ceramics, and composite materials. Grinding is also highly preferred for delicate materials like glass and silicon, where precision is critical.

This process is appropriate for the production of versatile surfaces, which can be cylindrical, circular, or even flat.

Key Considerations for Abrasive Selection and Use

There’s more to getting the most out of your grinding abrasive instruments than just selecting the appropriate wheel. For beginners, you must choose the right abrasive material to work with.

Conditions for using an abrasive depend on the following;

- Type of material being worked on.

- The abrasive type being used.

- The speed of abrasive.

- How much pressure is being exerted?

The following general guidelines provide the proper abrasive condition for each application.

- Grinding should be done with abrasive materials that are harder than the substance of the workpiece. Abrasive polishing materials are softer than that of the workpiece.

- Higher speed and lower pressure are associated with coarser abrasives.

- Lower speed and higher pressure are associated with finer abrasives.

- Use low-friability abrasives for grinding, while high-friability abrasives for polishing.

- Lapping is for abrasive materials with a Mohs hardness of 9 or 10.

Getting the abrasive conditions wrong can cause bad quality results, a worn-out abrasive, and a lot of heat you’d rather avoid.

Technical Specifications in Grinding

The success of any grinding operation largely depends on proper technical requirements to attain the best results while grinding.

Abrasive Material

The choice of grinding wheel impacts the grinding operation.

Manufacturers select different materials for specific purposes based on their unique properties.

- Diamond Wheels: used with pretty hard materials like glass, ceramics, and carbide

- Aluminum Oxide Wheels: preferred for steel and metal alloys because of a balance of cutting ability and toughness.

- Ceramic Aluminum Oxide Wheels: grinding of high-strength steel and alloys

- Silicon Carbide Wheels: ideal for cast iron, non-metallic, and non-ferrous metals.

- Cubic Boron Nitride (CBN) Wheels: used for tool steels, certain alloy steels, and high-speed steel.

Speed And Feed Rate

the rotational speed of the grinding wheel is very effective in the process. Higher speed can fasten the process but also increase the temperature, which causes thermal distortion of the workpiece. The workpiece should move relative to the wheel in a synchronized manner for optimal results. The workpiece is fed rate into the grinding wheel affects the precision and the surface finish.

Wheel Grade and Structure

the spacing (structure)) of the grains in the abrasive affect the speed at which the material is removed from the workpiece and the quality of the finish. The hardness (grade), which is the strength of the bond between the grains, depends on the type of material being ground. Harder wheels are for softer materials, whereas softer wheels are for harder materials.

Grinding Pressure

Pressure applied during the process impacts the grinding accuracy. It also affects the wheel wear and the rate of material removal.

Coolant Application

using the right coolant and applying it correctly reduces heat generation. It also lubricates the surfaces. Additionally, it washes away grinding dust and swarf and extends the life of the grinding wheel.

Bonding Material

abrasive grains are bound together by a material that affects the wheel’s performance. These materials might be resinoid, vitrified, or a metal.

Machine Parameters

factors such as horsepower, spindle speed, and machine rigidity (ability to resist deflection under load) significantly affect the level of precision and quality.

Types of Grinding Processes

Surface Grinding

This occurs when an abrasive wheel comes into contact with a flat surface of the workpieces, resulting in a smooth finish. The process is carried out on the surface grinder. The operator positions the workpiece on a table, and it moves horizontally beneath the rotating grinding wheel. This process is ideal for finishing flat surfaces, sharpening tools, and attaining optimal flatness.

The speed range for surface grinding machines is 5,500–6,500 fpm (28–33 m/s.) and a material removal rate of about 1 in³ per second depending on the abrasive material and workpiece hardness.

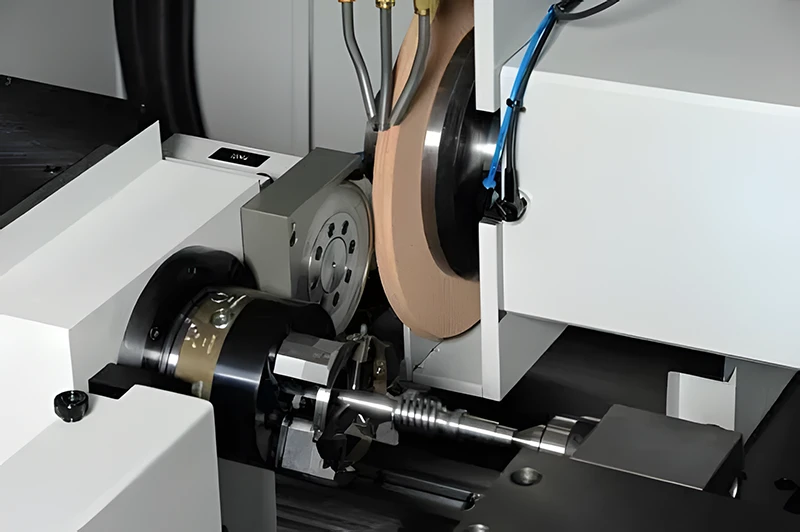

Cylindrical Grinding

Cylindrical Grinding is ideal for creating round parts. The workpiece rotates as it nears the grinding wheel which allows high precision of cylindrical surfaces. The processes are particularly useful in creating axles, shafts, and other cylindrical designs. The operational speed of the cylindrical grinder is between 5000-6500 fpm (25 to 33m/s), and the removal rate of 1 in³ per second.

Centerless Grinding

In centerless grinding, the workpiece is not mechanically held in place; instead, it is supported between the grinding wheel and a regulating wheel.

This method allows for high-speed and steady grinding of cylindrical components without the need for rest support. It is commonly used for grinding cylindrical parts that do not require светильники or centers, making it ideal for mass production of cylindrical objects. Centerless grinding can operate at speeds of about 4500-6000 fpm (23-30m/s) with a material removal rate of approximately 1 in³ per second.

Internal Grinding

As the name suggests, manufacturers use this method to finish internal surfaces. A small grinding wheel rotates to grind the internal parts of the workpiece, whether cylindrical or conical, to achieve the desired smoothness. This method is ideal for finishing cylinders, bores, and producing precise internal geometries. It operates at high speeds of about 6500-9500 fpm (33-48m/s) with a material removal rate of approximately 0.5 to 1 in³ per second.

Creep-feed Grinding

Creep-feed grinding is ideal for deep cuts and intricate shapes, differing from common grinding processes. During this process, the wheel moves slowly across the workpiece, removing a significant amount of material in a single pass and reducing the need for additional runs. The extremely slow feed rate and deeper cut make it suitable for producing specialized tools and sharpening cutting tools. The grinder typically operates at speeds of about 4000-600 fpm (20-30m/s) with a material removal rate of 1 in³ in approximately 20 to 30 seconds.

Jig Grinding

Jig grinding perfects dies, mold, jigs, and fixtures. This method offers the best results in situations demanding extreme precision. It’s particularly good at grinding intricate shapes and holes with great accuracy and a clean finish.

Gear Grinding

The technique of gear grinding produces very precise gears with a smooth surface. It’s typically reserved for those gears that need to meet exacting accuracy requirements and boast a high-quality surface. Commonly used in the aerospace and automotive industry for gear manufacturing requiring low noise and high-efficiency operation. The running speed is about 3,500 to 4,500 fpm (18 to 23 m/s), and the material removal rate of about 1 in³ every 30 seconds.

Thread Grinding

Thread grinding is used to produce нитки on nuts, screws, and various fasteners. Its excellence in making uniform and precise threads. Ideal for highly accurate threads on fasteners and is appropriate where tight tolerance and smooth thread finishes are needed. The operational speed is between 2000-2500fpm (10 to 13m/), and the rate of removal is 1 in³ in every 30 – 40 seconds.

Plunge Grinding

Plunge grinding specializes in finishing cylindrical surfaces and functions as a subtype of cylindrical grinding. In this process, the grinding wheel plunges radially into the workpiece, completing a single pass along its entire length. The grinder operates at speeds of about 6500 fpm (33m/s) with a material removal rate of 1 in³ every 20 seconds. This method is commonly used for grinding automotive parts, cylindrical rollers, and bearing races, making it ideal for high-precision cylindrical finishing.

Form Grinding

Form grinding is ideal for pieces that need to have a precise contour or profile since it uses formed grinding wheels to generate complex shapes. Used in the manufacture of items with unique forms, such as gear hobs and turbine blades. Have an operating speed of about 3,500–4,500 fpm (18–23 m/s) and a rate of material removal of 1 in³ in30 to 40 seconds

Profile Grinding

Super abrasive Machining

Super abrasive machining uses diamond or cubic boron nitride (CBN) grinding wheels with higher hardness and cutting power. Operating speeds exceed 6,500 fpm (33 m/s), and the rate of removal is 1 in³ in 10 to 15 seconds.

This technique excels in grinding extremely tough materials such as carbides, ceramics, and hardened steels. It finds extensive use in producing precise components for the automotive and aerospace industries.

Beyond the various types we’ve discussed, there is an extensive range of other grinding techniques, each suited to certain requirements depending on the kind of material, degree of precision, and required surface polish.

Advantages and Disadvantages of the Grinding Process

| Преимущества | Недостатки |

| High Precision and Accuracy | High Equipment Cost |

| Improved Surface Finish | Complex Setup and Operation |

| Ability to Machine Hard Materials | Limited Material Removal Rate |

| Versatility (used for various materials) | Risk of Thermal Damage(if heat not managed) |

| Complex Shape Fabrication( slots, grooves) | Costly Wheel Replacement |

| Consistency and Reproducibility (use of CNC machines) | Noise and Dust Generation |

| Limited Heat Generation (use of coolant) | |

| No Burr Formation. |

Заключение

Grinding is an integral and flexible process used in the manufacturing sector. A nuanced understanding of grinding processes is key to operational improvement for engineers and manufacturers. In the future, the world of manufacturing will have even more options as technology develops since better grinding tools and procedures will be available.