Medical injection molding is a specialized technique to create precision parts for the healthcare industry. The process involves injecting molten medical-grade polymers under high pressure into a mold to create precise and intricate parts. Given the critical nature of medical devices, it’s common in the healthcare industry to produce high-quality, consistent, and sterile products on a scale.

The capacity of medical injection molding to satisfy the stringent requirements of the medical field is what makes this process so significant. For medical components, the slightest flaw and contamination can potentially jeopardize patient safety; therefore, precision and hygiene are essential. Adherence to industry standards, such as FDA guidelines and ISO certifications, guarantees that the parts are secure, efficient, and appropriate for use in healthcare settings.

This molding process is a significant technology for the production of medical devices. It can produce components like implants, surgical instruments, and drug delivery systems.

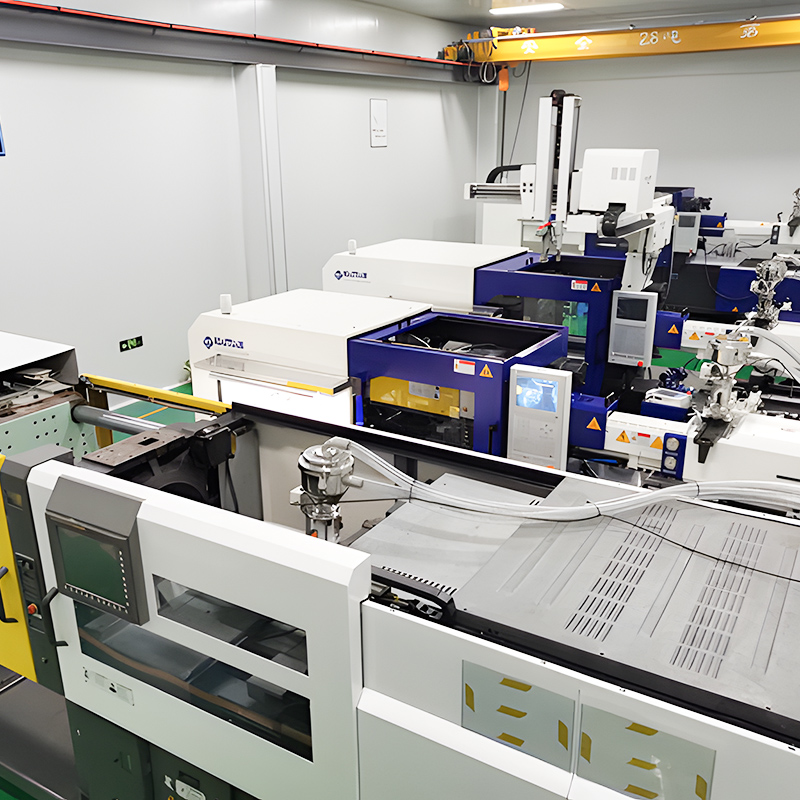

First Mold provides specialized medical injection molding services with advanced technology and expertise tailored to meet the healthcare sector’s demanding standards. With advanced equipment and experienced staff, they can deliver exceptional, tailored medical parts that meet the stringent requirements of the healthcare sector. The following link provides additional information about our medical injection molding capabilities: https://firstmold.com/industries/medical/.

Types of Medical Parts Manufactured Using Injection Molding

Medical injection molding manufactures medical devices that strictly follow quality, safety, and hygiene regulations. These devices can be disposable 또는 reusable.

1. Disposable Medical Items

Disposable medical parts are typically designed for single use to prevent contamination, ensure a high level of hygiene, and minimize the risk of infections. The injection molding process is crucial in developing high volumes of these items while maintaining their quality. The most often produced disposable medical items via injection molding are catheters, vials, and syringes.

주사기

To guarantee patient safety, syringes, for instance, require mass production with extreme precision and sterilization. People widely use them for injections, administering medications, and drawing blood.

카테터

Catheters require flexibility in design and sterility. These flexible tubes help administer medications or drain fluids, and their sterility prevents infection.

IV Tubing and Connectors

IV tubing is the flexible plastic tube that connects an IV bag to the patient’s vein using a catheter or a needle. The minor components of IV connectors link the tubing, IV bags, and catheters, forming a complete IV system. Combined, these components are used in intravenous therapy and are essential for delivering fluids and medications directly into a patient’s bloodstream.

Specimen Cups

They are an essential disposable medical tool serving medical labs, clinics, and hospitals. These containers collect and store body fluid samples like urine, stool, and saliva for diagnostic testing. Since these cups are disposable, they are produced in large quantities, ensuring sterility, uniformity, and leak-proof ability.

Blood Collection Tubes

The tubes are made using injection molding with medical-grade plastics or glass. Both materials offer durability and can withstand various storage and handling conditions. These tubes serve as single-use items to prevent cross-contamination. Additionally, they play a role in various diagnostic procedures to collect, store, and transport blood samples safely. They also conduct blood tests for conditions like blood chemistry imbalance and metabolic disorders. Each tube often contains specific additives like anticoagulants (e.g., EDTA or heparin) or clot activators, depending on the type of test being performed. Blood collection tubes have a vacuum-sealed system, allowing healthcare professionals to draw blood directly into the tube without extra steps. The tubes are then sealed tightly, preventing leaks or exposure during transport to a laboratory.

1. Reusable Medical Items

Reusable medical parts are designed to be used multiple times. They can withstand repeated and harsh sterilization processes such as autoclaving (high-temperature steam). The materials should also be durable enough to endure cleaning without compromising functionality.

2. Surgical Instruments (e.g., forceps, retractors)

In surgical procedures, forceps are hand-held instruments that grasp or hold tissues, blood vessels, or other objects. Forceps come in various designs, from fine-tip forceps for delicate procedures to more extensive, stronger versions for grasping more inflexible tissues.

Retractors: Conversely, retractors are used to retract tissues or organs by providing the surgeon with unobstructed visibility and access to the surgical area.

Precision in design and manufacture enables surgeons to perform their tasks accurately. Manufacturers use high-grade stainless steel or other durable metals, along with injection-molded plastic handles or parts, to improve usability (ergonomics or insulation) and safety. These precision instruments serve multiple purposes in operating rooms.

3. Endoscopic Instruments

They are used in minimally invasive surgeries. Key endoscopic instruments include biopsy forceps, endoscopes, scissors, and graspers. Sterileness is non-negotiable, provided these tools come in direct contact with internal body parts. These tools are also designed for repeated use after proper sterilization.

4. Dental Instruments

Instruments like dental mirrors, explorers, and probes are molded for precision and reuse. Medical-grade plastics or stainless steel are the preferred materials for manufacturing this equipment. They guarantee their durability and ability to endure sterilizing, allowing dentists to perform various procedures with accuracy and ease.

5. Orthodontic Appliances (e.g., braces, brackets, arch wires, retainers)

Patients wear long-term medical devices to correct dental alignment and improve their oral health. They are intended to be worn for extended periods—typically several months to a few years—and durability and safety are paramount. Medical-grade stainless steel, ceramics, and thermoplastics are frequently utilized as molding materials because they are biocompatible and resistant to wear and corrosion.

6. Orthopedic Implants (e.g., artificial joints)

Artificial joints, or orthopedic implants, are medical devices that replace or support diseased or injured bone components. Joints like the hip, knee, and shoulder are typical examples.

Durability and biocompatibility are critical for orthopedic implants, so they must meet strict safety and efficacy standards. Due to their prolonged presence in the body, they must interact safely with body tissues without causing adverse reactions.

7. Sterilization Trays

Sterilization trays are specifically designed to hold, organize, and protect surgical instruments during sterilization processes. They need to be reusable and resistant to pressure and extreme temperatures.

8. Respiratory Masks (Reusable Types)

Unlike disposable masks, advanced respiratory devices are designed for reuse and made from more durable materials that can be cleaned and used repeatedly. They are often made from high-performance materials like nylon or polyester, and the filtration layers have activated carbon or HEPA filters.

Types Of Injection Molding Used In Medical Devices

1. Conventional Injection Molding

This injection molding process is widely used to make various medical devices. It involves melting plastic pellets or other materials and injecting them into a mold cavity under high pressure. This method is highly efficient for producing medical parts with high precision and intricate geometries. Examples of medical parts produced are syringes, Specimen cups, and IV components.

2. Thin Wall Injection Molding

Thin-walled injection molding is a specialized process for manufacturing parts with extremely thin walls, typically under 1mm thick. The thinness of the wall is important because the size of the part limits how thin the wall can be. It is commonly used in the medical industry, where lightweight and high-strength components are essential. Thin-walled injection molding significantly saves on cost, so it’s most preferred for high-volume production. The main applications for this process include small enclosures for medical devices.

3. Over Molding

Over-molding is an advanced technique that involves molding one or two components over a preexisting structure, resulting in a robust and durable grip. It eliminates the need for assembly after molding. Over molding creates handles for surgical instruments and can also enhance medical products without metal parts. For example, silicones or thermoplastic elastomers (TPE) mold onto thermoplastic substrates.

4. Insert Molding

Insert molding can add durable or structural elements within plastic parts, though for medical components like IV connectors, plastic-only designs are preferred for biocompatibility. Plastic can be injected around metal inserts, magnets, or electrical components to form a cohesive part by placing them in the Mold.

5. Liquid Silicone Injection Molding

Liquid silicone rubber (LSR) injection molding produces flexible, biocompatible parts that withstand extreme temperatures, chemicals, and aging. The process used two-part liquid silicon rubber injected into a mold and cured to achieve the end-use properties.

LSR is ideal for medical devices that require flexibility and biocompatibility, making it suitable for items like catheters and seals that often contact skin or bodily fluids.

Another benefit is that silicone is biologically inert, which allows for safe implantation into the body since it doesn’t react with biological tissue.

6. 2-Shot Molding (Two-Shot Molding)

2-shot molding is a designated technique where the process molds and over-molds the medical device or component in a single operation. It begins by forming a basic shape, and then additional material fills the remaining space to add a different texture or color. This process allows for the creation of parts with intricate designs and combining various materials to enhance functionality and appearance within a single production step. With higher-volume programs, this process can offer some cost savings.

7. 3D Printing

Though not technically a form of injection molding, 3D printing is commonly used to create prototypes and test the design before it is injected. 3D printing technique can also print the actual injection molds using either metal or plastic. For some medical devices, metal is not necessary to create a mold, so plastic is the preferred material.

Materials Used in Medical Injection Molding

The most common materials in medical molding are thermoplastics. These materials quickly melt into a molten state and move through a barrel into a mold. Since the injection molding method works with a wide variety of plastic materials, it serves as an excellent choice for producing pharmaceutical and medical parts using any medical-grade plastic required for the project.

Various plastics suitable for the operations offer their unique properties and performance. Some of the common types are:

폴리에틸렌(PE)

Polyethylene, a common thermoplastic, serves various commercial and industrial purposes. It comes in several forms, including LDPE, HDPE, and UHMW, each offering a different level of rigidity and durability. Manufacturers often use UHMW in knee, hip, and other joint prostheses.

폴리프로필렌(PP)

Polypropylene is one of the most popular plastics. It stands out for its toughness, flexibility, and long-lasting durability, along with a strong resistance to chemicals and electrical currents. It is preferred for disposable medical devices like syringes and specimen containers.

Polystyrene(PS)

Polystyrene is a hard plastic with little to no flexibility. However, it exhibits excellent machinability, good impact resistance, and decent dimensional stability. This makes it ideal for creating critical medical components like Petri dishes, diagnostic parts, and culture trays.

폴리카보네이트(PC)

Polycarbonate is transparent and has excellent mechanical properties. This strong engineering-grade thermoplastic offers dimensional stability and flame-retardant properties. It is highly compatible with body tissues, making it ideal for medical equipment manufacturing. It also withstands damage from impacts, high temperatures, and UV exposure.

PEEK

Polyetheretherketone (PEEK) is a high-quality thermoplastic with exceptional mechanical properties, including resistance to harsh environments such as thermal degradation, wear, tracking, and radiation. PEEK creates medical and surgical implants by offering exemplary dimensional stability even after exposure to stress.

실리콘

This chemically inert compound is similar to synthetic rubber and offers exemplary mechanical properties and compatibility with biological tissues. Silicone is the go-to option for medical-grade plastic polymer for the vast production of devices such as connectors, catheters, and tubing.

결론

Medical injection molding makes manufacturing premium medical components and equipment more accessible. Its accuracy and effectiveness have contributed significantly to meeting the high standards needed in the healthcare sector.

First Mold Company is your best choice for superior medical injection molding services. Our team’s expertise and dedication will ensure that your medical products are made with the highest care and quality. For reliable injection molding solutions, First Mold is the way to go!