Family Molding Service

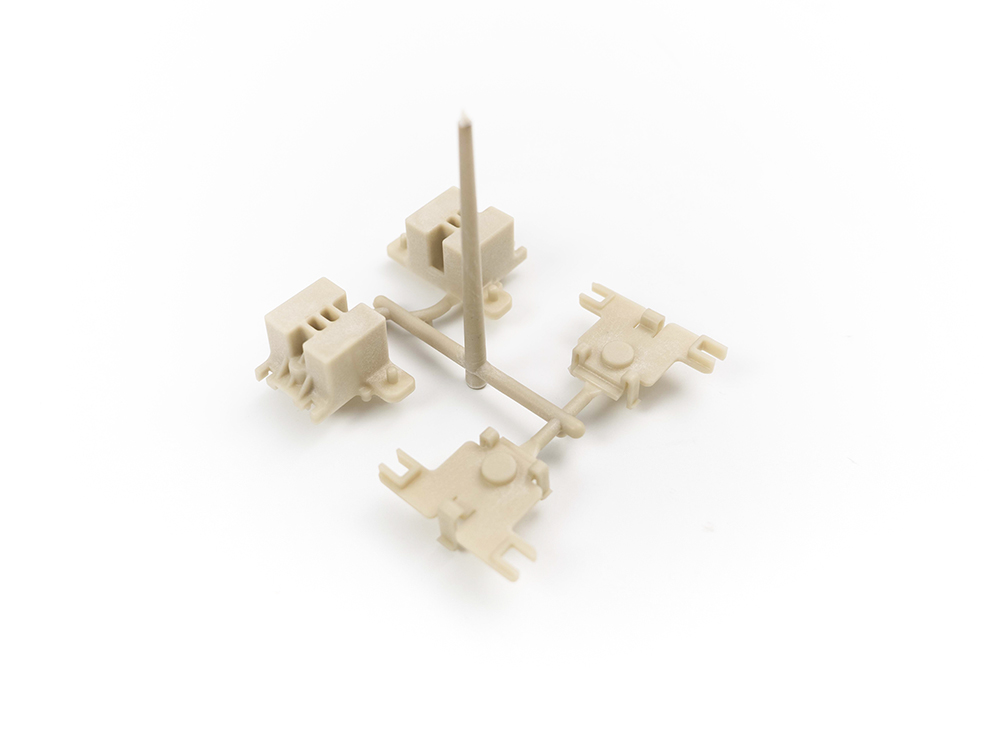

Family molding, where different parts are produced simultaneously with one set of molds.

Custom Family Injection Molding Solutions

We offer all our clients the options of low-cost one-stop-shop family molding solutions. While our family molds using the same colors, our post-processing solutions can finish individual components of your parts in a different array of ways. We are very relationship-focused. This is why many of our solutions can be customized to meet your project requirements.

귀사의 제조를 위한 당사의 장점과 혜택

리드타임 단축을 통한 시장 우위 확보

마감일이 촉박하신가요? 경쟁에서 이기고 싶으신가요? 유니티의 사내 역량과 검증된 제조 공급업체 네트워크를 통해 부품을 즉시 생산에 투입할 수 있습니다.

Unbeatable Design Support

Our design team consists of experts that will help bring the best value out of your project. From our practical design-for-manufacturing evaluation to our immense attention to detail, you can be assured of making beautiful, functional designs every time you work with us. We open your project to different design possibilities and complex geometric configurations, all made feasible with CNC machining and precision injection molding

Tight Tolerances

At Firstmold, we are capable of using optimized processes to make family mold tooling and components with high precision and tolerances of up to 0.010”. Should tighter tolerances be required, we shall evaluate the feasibility, while leadtimes and production costs will increase.

Zero MOQs

At Firstmold, we work with every client irrespective of their volume needs. Our family injection molding solutions are open to everyone. Need low-volume parts? choose our Rapid Aluminum Tooling option. We have zero minimum order quantities to meet the budget or production requirements of all our clients.

Lower Production and Tooling Cost

Our Family Injection molds are an efficient method of making functional parts with multiple components. With these family molds, multiple components of the same part can all be made in one tool and one injection molding, saving thousands of dollars on making individual tooling and molding cycles.

One-stop-shop Services

Firstmold is with you from start to finish. Our complete suite of services mean that we will be with you from design validation to insert molding, post-processing and other finishing services. We simply don’t stop until your end product emerges exactly how you envisioned it.

Seamless Ordering

Firstmold family injection molding makes your part ordering and inventory easier to manage and track. With one order, full sets of parts can be made without worrying about raising orders for individual components in your part.

See What Our Customers Said

“When we first requested CNC machining, we tried to contact First Part.They responded within hours with prices, delivery times and suggestions for our requirements. I am really satisfied with their professional service and high quality control. I would recommend them to my friends Without hesitation.”

──Brown Abraham

── Jackon Brown

Free & quick DFM FEEDBACK WITHIN 24HRS

Family Injection Molding Manufacturing & Processing

Family injection molding is a delicate process that requires adherence to strict processing parameters to guarantee defect-free parts and components. We achieve the high level of consistency and quality by ensuring we process the mold tool to the tightest of tolerances. There are 3 criteria to be met for our family injection molding. First, the part must be of the same color and material. Next, parts must be ordered and in the same quantity as the molding of each component occurs simultaneously. Lastly, the parts must be almost equal in size and volume to one another to prevent short shots and underfills. At Firstmold, our design experts and engineers are adept at mold fill simulations, helping you mitigate the risks of defects. Our molding equipment has zero downtimes, running 24/7 to truncate delivery times and meet customer timeline expectations. We achieve mold tolerances up to +0.010 inches for parts that require the highest precision and dimensional accuracy, and offer a “Lifetime mold guarantee System” that stores and maintain our clients mold indefinitely for a small token of storage fee. This way, you can be rest assured that your molds will remain in the best shape over the cycle of production it was intended.

자료

Choose from simple commodity plastics to high-performance engineering-grade resins to deliver all the required properties in your plastic injection molding parts. We also stock frequently requested and popular resins in-house to bolster our supply chain for quick-fire projects. Below are some of the categories of materials we work with:

Stock materials – PP, PVC, PS, PE, HIPS, PET | ABS, PC, POM, Nylon/PA66, PBT

Stock materials are the most popular on-the-market material solutions that fit into the everyday needs of conventional molding. These materials are more readily available and affordable for use.

Custom materials

Explore custom materials made for special production or product-use cases. Our custom materials are well engineered to deliver enhanced performance.

Learn more about our molding materials

마감

We have the capability to process finished parts into any desired finish and texture in line with the SPI standards. Our finishing options strike a balanced mix between cosmetic and aesthetic applications. All our injection molded parts can be finished in 4 basic options. These include:

· Standard Finish

Usually SPI B-2 Standard. The standard finish will have your parts delivered as molded with no significant cosmetic inputs on interior facing and non-aesthetic sections of your part.

· Textured/Grained

Textured, grained or patterned surfaces ranging from matte to swirl, lines, mesh and more. Texturing may be done via mold texturing or via post-processing techniques.

· Regular Polished

Regular polishing to keep part surface smooth and uniform. High to low luster that delivers a clean, presentable appearance.

· Mirror Polished

부품 표면의 디테일과 반사율이 우수하고 광택이 높습니다. 표면이 밝고 광택이 나며 고급스러운 룩앤필을 구현합니다.

· Other Finishing Capabilities

퍼스트몰드로 부품의 최종 마무리를 완료하여 시간과 비용, 물류 노력을 절약하세요. 성형 후 다양한 2차 가공 옵션을 제공하여 부품을 장식, 브랜드화 및 맞춤화할 수 있습니다. 현재 2차 작업에는 다음이 포함됩니다:

- UV 코팅

- 실크 또는 패드 인쇄

- 크롬 도금

- 레이저 에칭

- 라벨링

- 인그레이빙

- 스레드 인서트

- 미디어 블라스팅

- 어셈블리

- 페인팅/스프레이 페인팅

- 다른 마감 기능에 대해 자세히 알아보기

산업 분야

Firstmold serves a broad range of clients across a range of industries. Our manufacturing solutions are widely employed in the medical, consumer products, automotive, aerospace, Robotics & Automation and defense industries. We have over 20 years of experience in prototype development, product development and mass production during which we have evolved along with the industry-best practices, equipment and capabilities. Our pool of seasoned engineers are adept at optimizing design and executing production with high precision. We provide a superior advantage garnered through our understanding of the different context and nuances for product development across every industry.

자동차

Aerospace and Defense

의료

Optimize efficiency, reduce weight and mitigate flight risks with our custom manufacturing materials for the aerospace industry.

Surgical-grade parts, wearables and bio-compatible components that meet FDA requirements to deliver life-saving solutions.

전자 제품

소비자 제품

Robotics & Automation

Achieve tight tolerances and complex geometries in consumer electronic products to cater to the various style and class of your end-users.

Create exquisite design that is affordable and scalable to cater to the ever-changing consumer product trends.

Eliminate downtimes and boost efficiency with on-demand components that keep production running while integrating with existing lines and complimentary technology.

Additional Resources & FAQs

1. What is Family injection molding?

Family injection molding is a molding technique that creates multiple components of the same family of parts in a single injection molding cycle.

2. How does it work?

Family molding works the same way as injection molding, however, instead of designing the mold to house one part, family molds contain multiple cavities for different individual components that make up the part.

3. Why should I use Family injection molding?

There are many benefits of using family molding. Some of the most common advantages include consistency, higher cost efficiency, quicker leadtimes and easier ordering.

4. When should I choose Family injection molding?

Choose family injection molding when multiple components of your parts are going to be made from the same materials of thermoplastics, same color and same order volumes.